Equipment and method for recovering waste circuit boards

A technology for waste circuit boards and recycling equipment, applied in electronic waste recycling, plastic recycling, recycling technology and other directions, can solve the problem of resin ring fiber powder being discarded and not being built.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

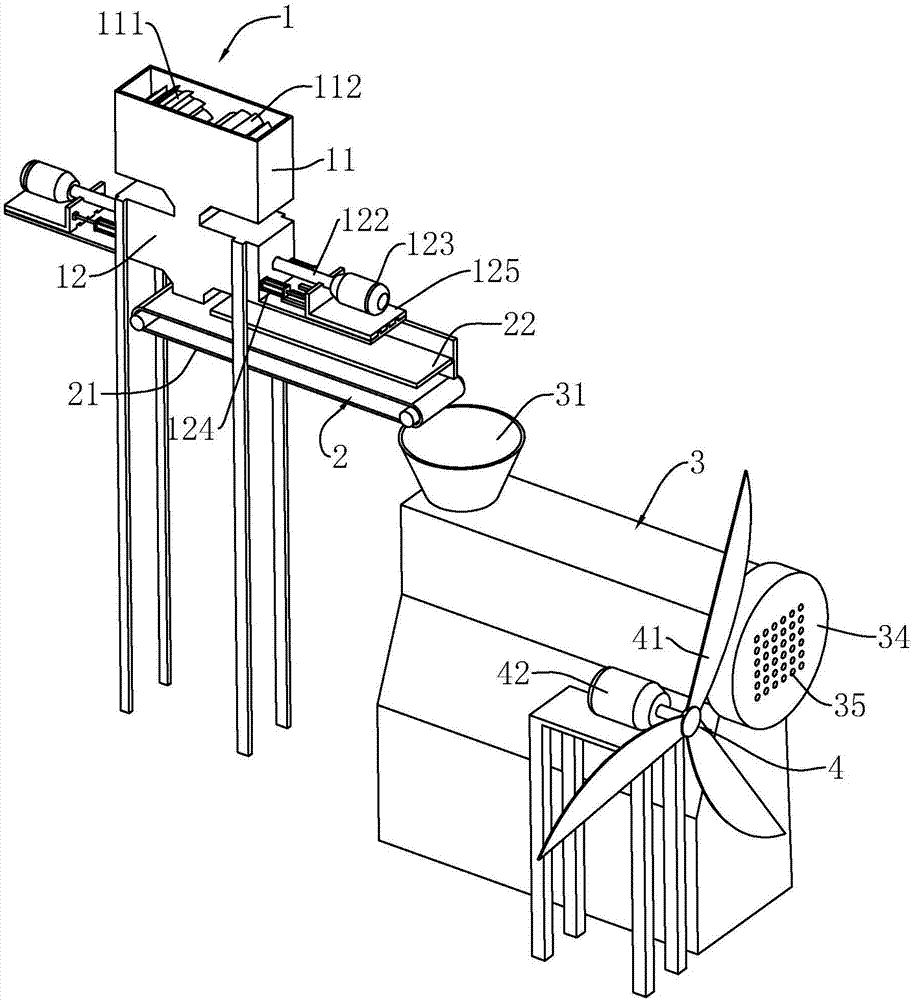

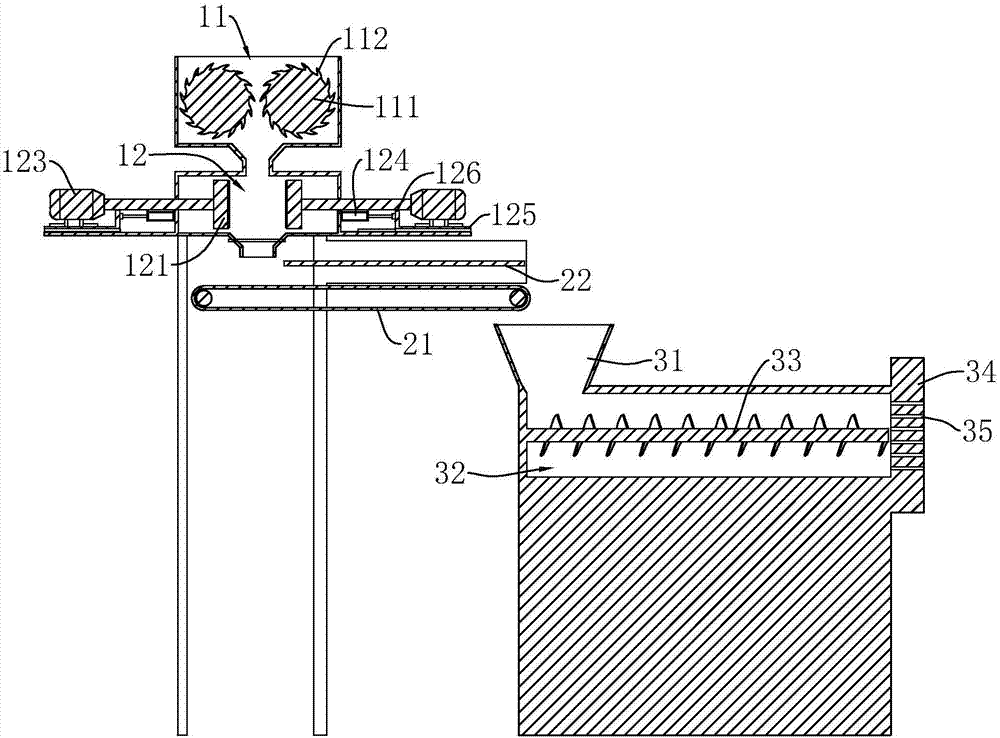

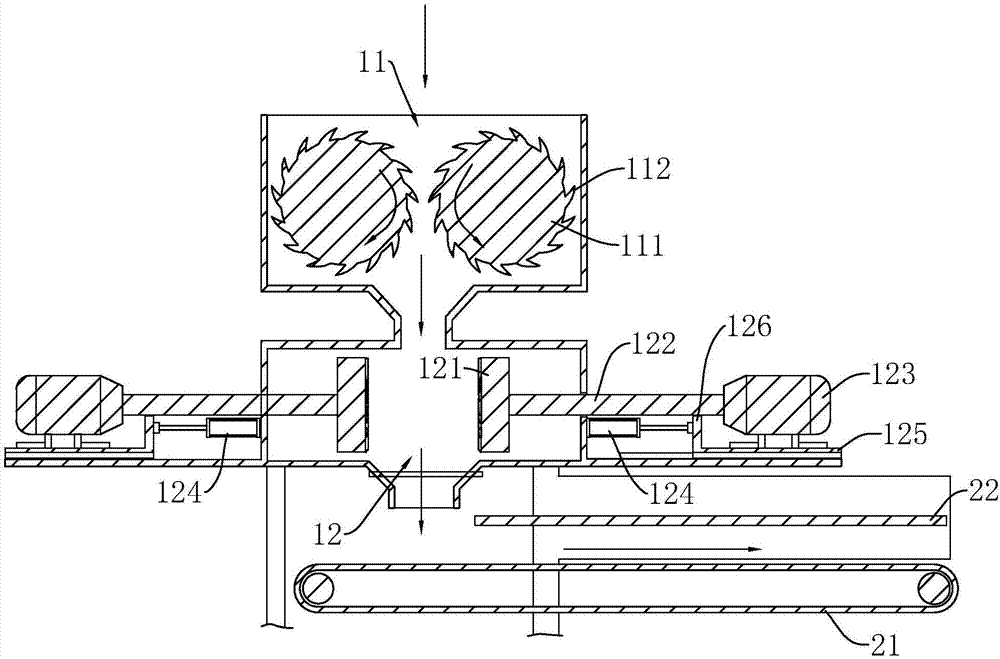

[0039] A recycling device for waste circuit boards provided in this embodiment has a structure such as Figure 1-4 shown.

[0040] Such as figure 1 As shown, the waste circuit board recovery equipment includes a crushing mechanism 1, a sorting mechanism 2, a mixing mechanism 3 and a pelletizing mechanism 4 arranged in sequence.

[0041] Wherein, the crushing mechanism 1 includes a slitting chamber 11 and a crushing chamber 12 arranged vertically. The discharge opening below the crushing chamber 12 faces the conveyor belt 21 . The other end of the conveyor belt 21 extends above the feed opening 31 , and an electromagnet 22 is arranged above the conveyor belt 21 .

[0042] The feeding port 31 communicates with a mixing chamber 32 , and the other end of the mixing chamber 32 is provided with a detachable die 34 . An outlet 35 is provided on the die head 34 .

[0043] The cutting knife 41 is controlled by the pelletizing motor 42 and sweeps the outlet intermittently.

[0044...

Embodiment 2

[0058] A method for recycling waste circuit boards, comprising the steps of:

[0059] S1. Crushing waste circuit boards into crushed materials with a particle size of no more than 80 meshes;

[0060] S2. Removing the metal material in the crushed material by magnetic field separation to obtain resin ring fiber powder;

[0061] S3. Mix the resin ring fiber powder with the reinforcing agent and plastic to obtain the glass-plastic mixture. The ratio of the mixed mass of the three to the total mass is 35% to 50% of the plastic, the reinforcing agent is not less than 15%, and the rest is resin ring fiber pink;

[0062] S4, heating the glass-plastic mixture to obtain the glass-plastic mixture particles;

[0063] S5. Obtain glass-plastic handicrafts by means of hot pressing, extrusion molding, and the like.

[0064] Wherein, the resin ring fiber powder obtained in S2 is air-dried so that the moisture content of the resin ring fiber powder does not exceed 6%. During the separation...

Embodiment 3

[0066] A composite floor, including the glass-plastic layer prepared by the recycling method in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com