Degradable non-toxic sucker material with cold and hot application

A straw, hot and cold technology, applied in the field of degradable non-toxic cold and hot straw materials, can solve the problems of poor heat resistance, consumption of wood and metal resources, water resistance, etc., to achieve good use effect, easy to absorb beverages, Good heat resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

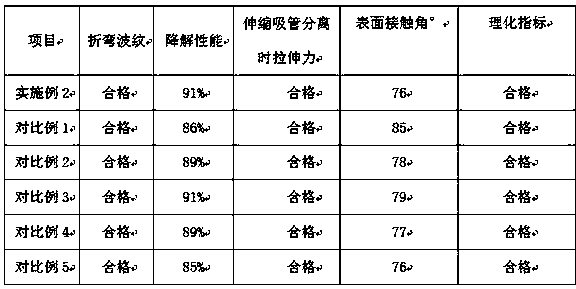

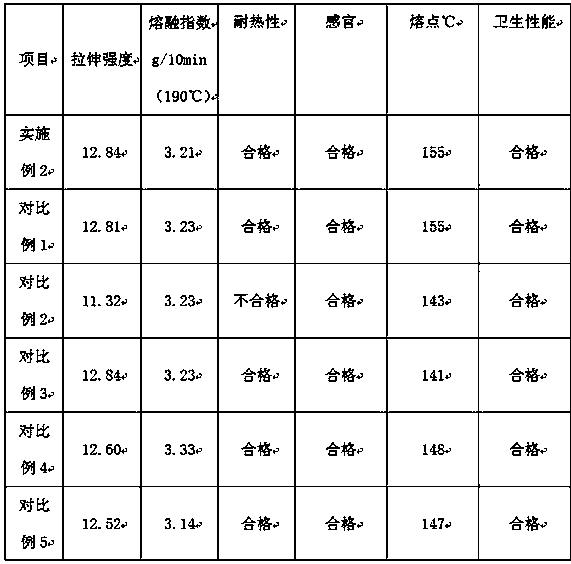

Examples

preparation example Construction

[0027] A degradable non-toxic cold and hot straw material is characterized in that its preparation method comprises the following steps:

[0028](1) Weigh each raw material, add hydroxyapatite powder, calcium phosphate, bagasse fiber, mung bean starch, polyvinylpyrrolidone, stabilizer, regulator, sodium alginate into the high mixer, heat up to 70°C, add Mix xanthan gum and konjac mannan evenly, then cool down to 60°C, add glycerin and polyethylene glycol, stir for 3 minutes, and discharge evenly to obtain mixture A;

[0029] (2) Add POE to the internal mixer, raise the temperature to 150°C, banbury and add polylactic acid, polycyclohexyl carbonate, polyhydroxyalkanoate at the same time, keep the temperature for 10 minutes and then discharge the mixture to obtain the mixture B ; (3) mix the mixture A and mixture B obtained above evenly, banbury for 3 minutes, granulate through an extruder, extrude, and draw to form a straw; (4) shape the straw At a volume concentration of 0.20...

Embodiment 2

[0034] A degradable and non-toxic cold and hot straw material is mainly prepared from the following raw materials in parts by weight:

[0035] 4.3 parts of hydroxyapatite powder, 2.1 parts of tricalcium phosphate, 105 parts of polylactic acid, 13 parts of polycyclohexyl carbonate, 15 parts of polyhydroxyalkanoate, 23 parts of bagasse fiber, 16 parts of glycerin, 13 parts of mung bean starch, poly 6.5 parts of ethylene glycol, 4.7 parts of polyvinylpyrrolidone, 1.4 parts of xanthan gum, 1.2 parts of konjac mannan, 0.6 parts of stabilizer, 0.5 parts of regulator, 1.4 parts of sodium alginate, and 12 parts of POE.

[0036] A degradable non-toxic cold and hot straw material is characterized in that its preparation method comprises the following steps:

[0037] (1) Weigh each raw material, add hydroxyapatite powder, calcium phosphate, bagasse fiber, mung bean starch, polyvinylpyrrolidone, stabilizer, regulator, sodium alginate into the high mixer, heat up to 80°C, add Mix xanthan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com