Color belt tensioning mechanism of intelligent card lithoprint device

A technology of tensioning mechanism and smart card, applied in inking device, printing and other directions, can solve the problems of increasing production cost, occupying large space and high technical requirements, and achieving the effect of reducing production cost, easy disassembly and assembly, and simplifying the overall mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

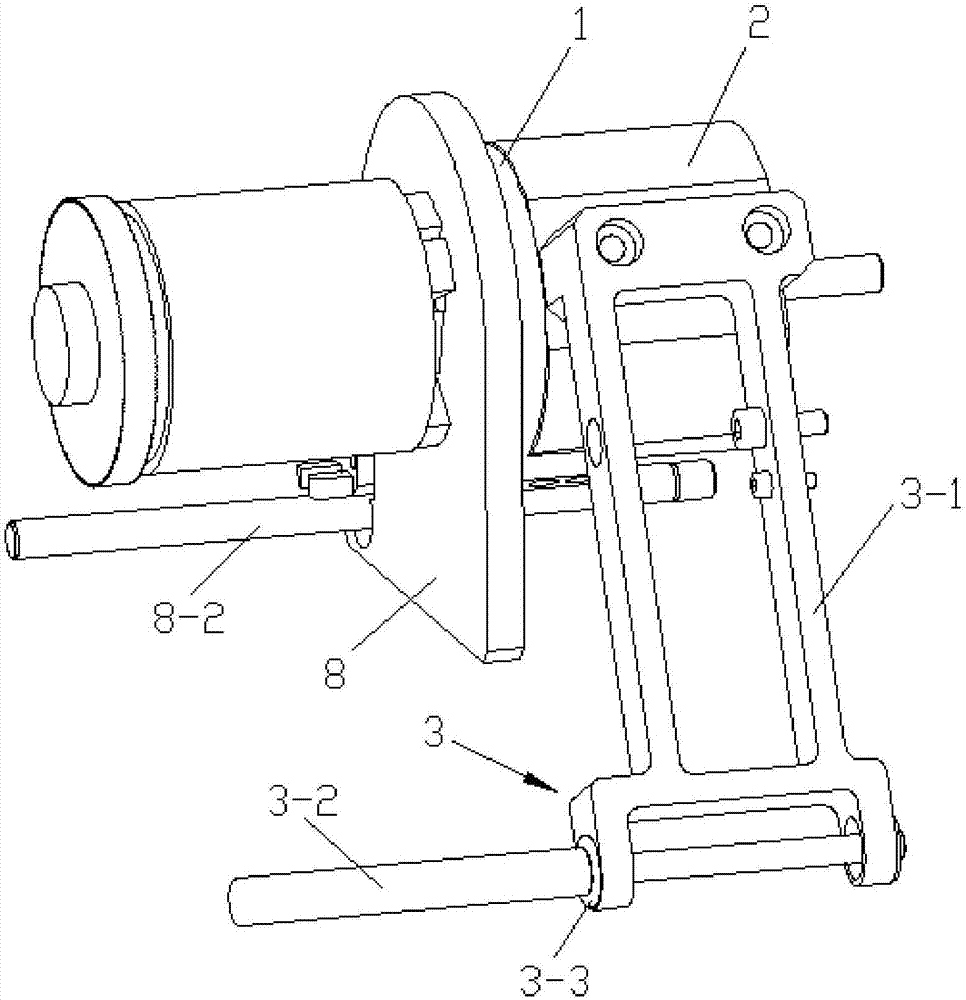

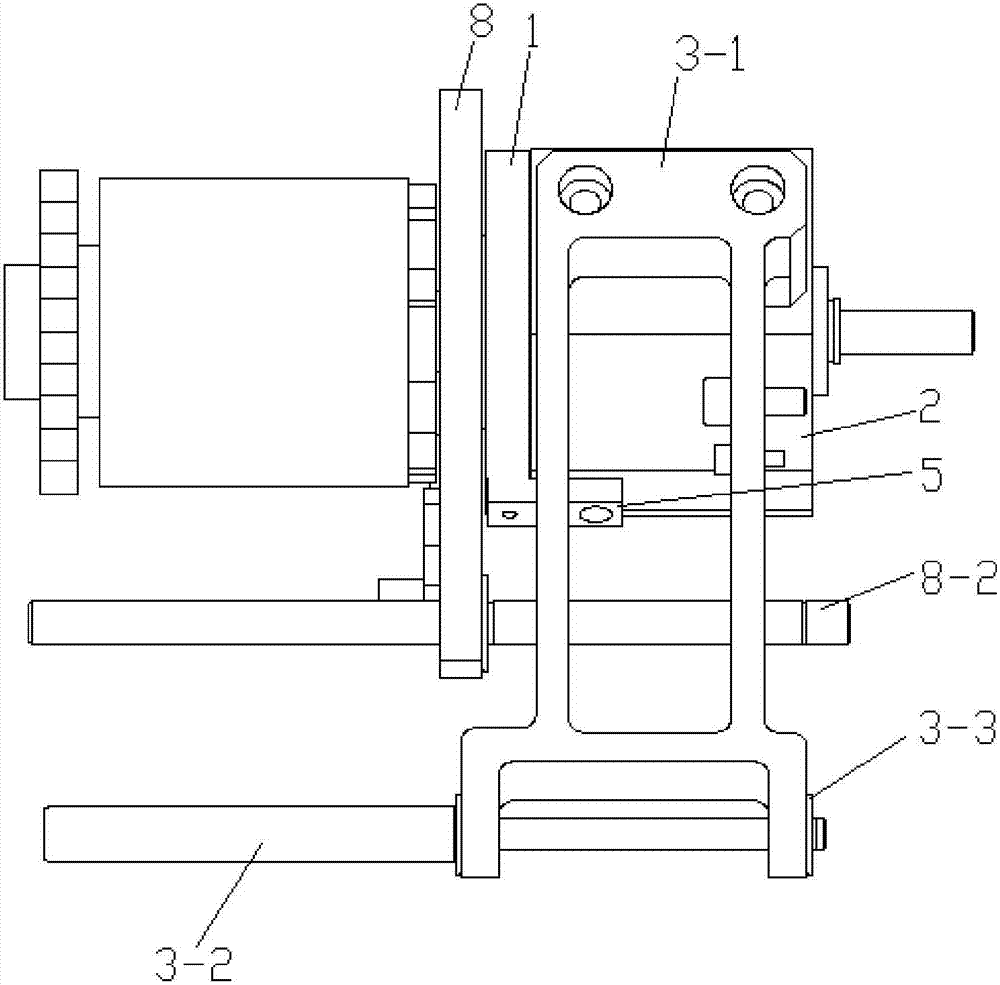

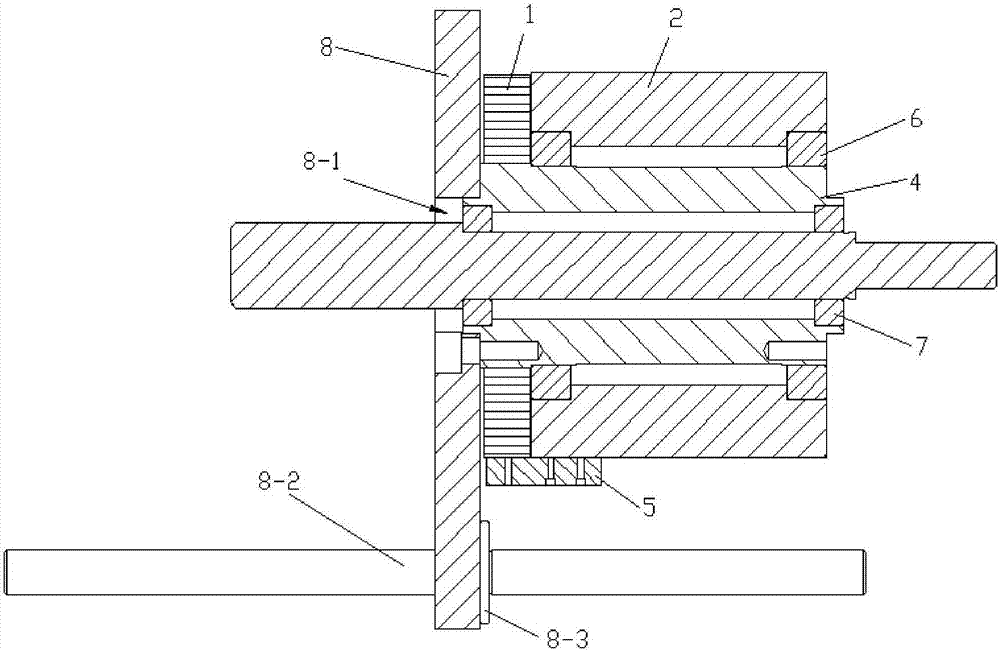

[0030] see Figure 1-6 , the ribbon tensioning mechanism of a smart card offset printing device in this embodiment includes a coil spring 1 and a rotation control mechanism fixedly connected to the coil spring 1, and the rotation control mechanism includes a rotation connecting cylinder 2 and a limiter for the ribbon. The tension control assembly 3 in the position, the rotating connecting cylinder 2 is provided with a fixed sleeve 4, the fixed sleeve 4 is coaxially arranged outside the drive shaft for retracting and unwinding the ribbon, and the rotating connecting cylinder 2 is rotatably connected to The tension control assembly 3 is fixedly connected to the rotating connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com