Brick-making raw material conveyor

A conveyor and raw material technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of lack of push settings, the height of both ends cannot be adjusted at the same time, easy hardening and solidification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

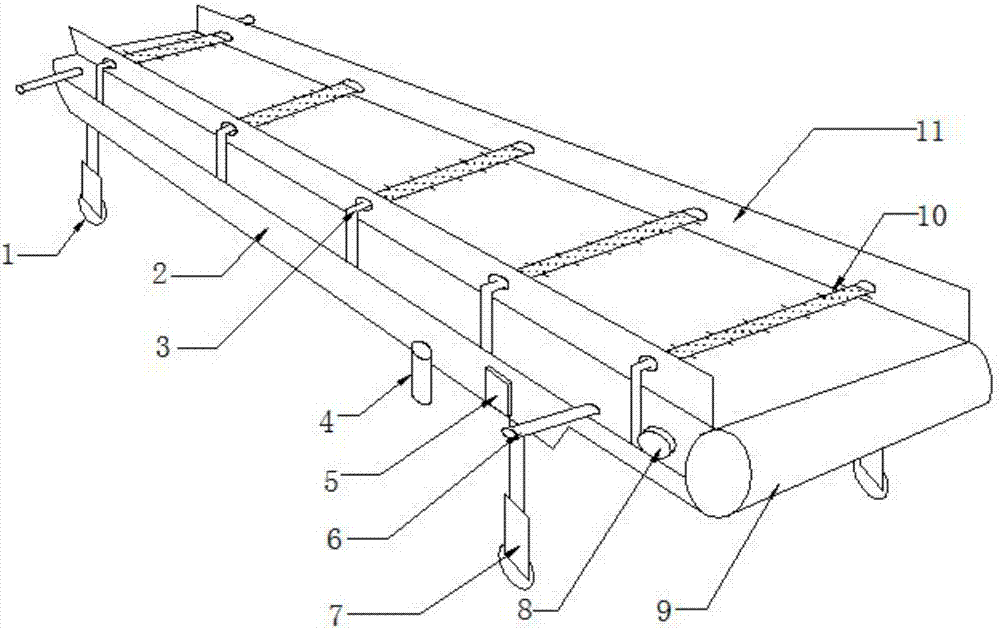

[0016] Such as figure 1 As shown, the present invention provides a kind of brick material conveyor, including wheels 1, body 2, drive shaft 3, motor 4, controller 5, handle 6, electric lift rod 7, conveyor belt 9, mixing shaft 10 and guard plate 11; The machine body 2 is provided with a conveyor belt 9 for transporting brick-making raw materials. Both sides of the conveyor belt 9 are equipped with guard plates 11, which prevent the leakage of the raw materials. The guard plate 11 is provided with multiple stirring shafts 10, 10 through the rotation to drive the rotation of the iron hook for stirring, the stirring shaft 10 is movably connected with the guard plate 11 through the transmission shaft 3, the transmission shaft 3 drives the rotation of the stirring shaft 10 through rotation, and there are multiple handles on both sides of the body 2 6. It is convenient to push the conveyor manually. The motor 4 and the controller 5 are respectively provided on one side of the body 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com