Tubular ultrasonic separation cavity

A separation cavity, tube-shaped technology, applied in the chemical/physical/physical-chemical process of applying energy, mechanical oscillation water/sewage treatment, water/sewage treatment, etc. Ultrasonic concentration or separation device processing capacity limitation, affecting processing efficiency and other problems, to achieve the effect of expanding the scope of industrial applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

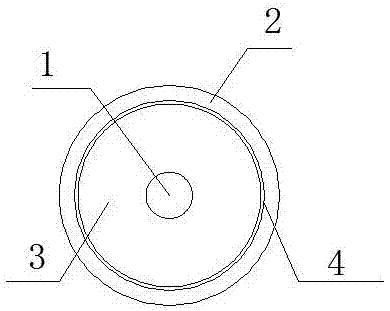

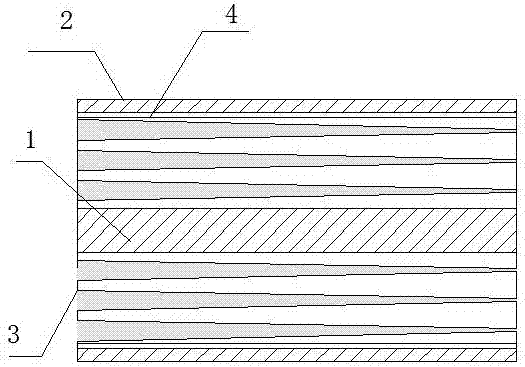

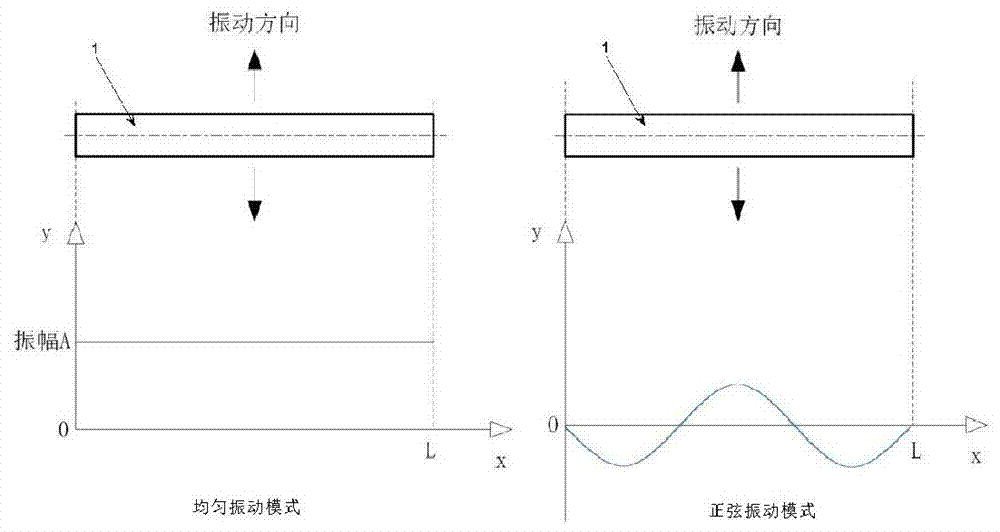

[0022] Such as figure 1 , 5 As shown, a tubular ultrasonic separation chamber includes a columnar ultrasonic vibration source 1 and a tubular reflector 2, characterized in that: the columnar ultrasonic vibration source 1 is in the tubular reflector 2, and the columnar ultrasonic vibration source 1 An annular cavity 3 is formed between the tubular reflector 2 , and the inner wall of the tubular reflector 2 is provided with an acoustic reflection material 4 . Between the columnar ultrasonic vibration source 1 and the tubular reflector 2 is an annular cavity 3, in which various fluid media to be treated can pass through. The fluid medium to be treated can have two kinds of motion states: static state and axisymmetric laminar flow state. The function of the tubular reflector 2 is to reflect almost all the sound waves transmitted through the fluid medium to be treated back to the fluid medium to be treated, thereby forming a standing acoustic wave in the fluid medium to be treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com