A method for supercritical carbon dioxide extraction of ursolic acid from Ligustrum lucidum

A technology of carbon dioxide and Ligustrum lucidum, applied in organic chemistry, steroids, bulk chemical production, etc., can solve the problems of long extraction time, large amount of organic solvent, environmental pollution, etc., and achieve good reproducibility and high extraction efficiency High, process-stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

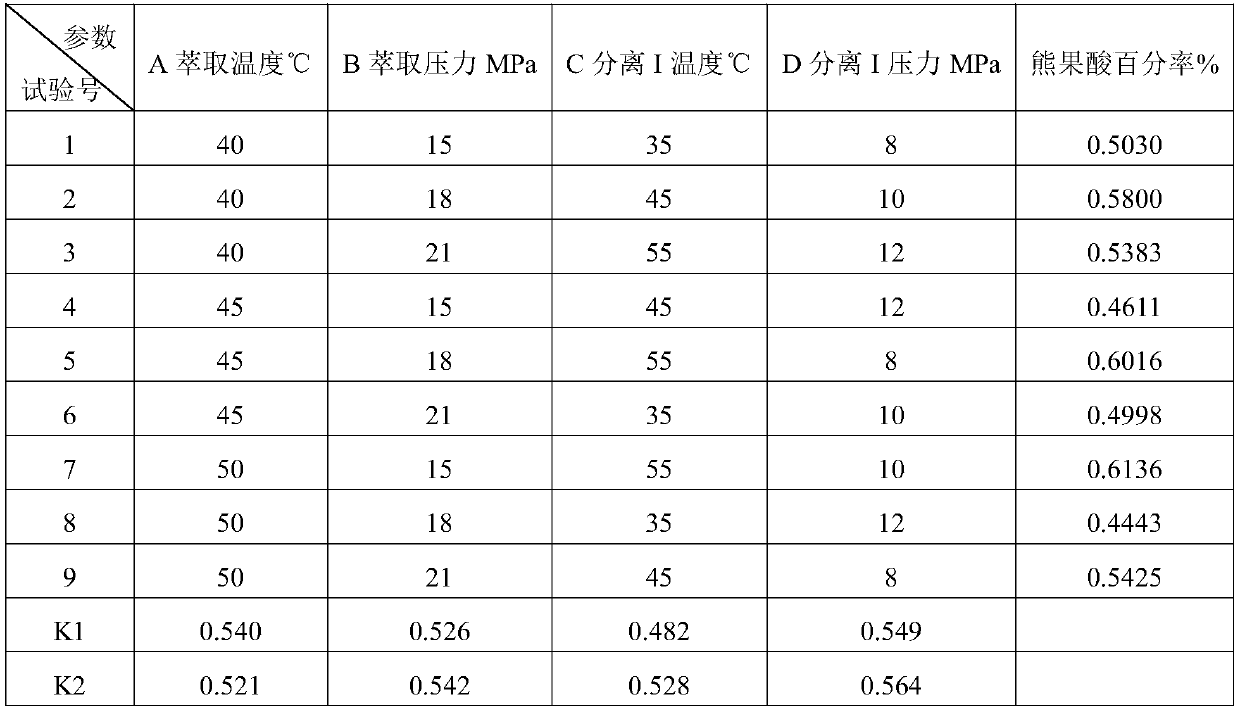

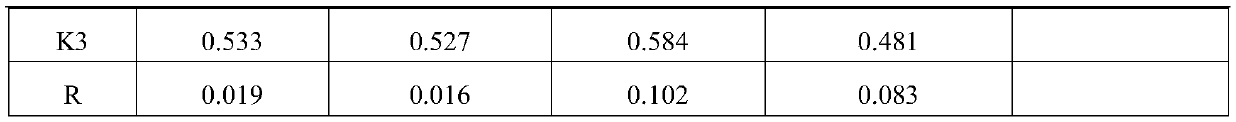

Method used

Image

Examples

Embodiment 1

[0023] The method of embodiment 1 supercritical carbon dioxide extraction Ligustrum lucidum ursolic acid

[0024] S1, pretreatment: pulverize Ligustrum lucidum to 50 mesh for later use;

[0025] S2, feeding: take by weighing 200g of privet fruit powder pulverized in step S1, put it into the extraction kettle of the supercritical carbon dioxide extraction device, tighten the extraction kettle cover, and check whether the separation kettle cover and the relevant valve are in a closed state;

[0026] S3. Heating process: start the power supply, connect the cooling water, start the refrigerant switch, and turn on the heating switch of the extraction kettle and the separation kettle, and set the temperatures of the extraction kettle and the separation kettle I, II, and III to 35°C and 35°C respectively. ℃, 45℃, 45℃;

[0027] S4. Boosting process: When the temperature of the refrigerator drops to 5°C, and the temperature of the extraction kettle and the separation kettle reaches th...

Embodiment 2

[0029] The method of embodiment 2 supercritical carbon dioxide extraction Ligustrum lucidum ursolic acid

[0030] S1, pretreatment: pulverize Ligustrum lucidum to 50 mesh for later use;

[0031] S2, feeding: take by weighing 200g of privet fruit powder pulverized in step S1, put it into the extraction kettle of the supercritical carbon dioxide extraction device, tighten the extraction kettle cover, and check whether the separation kettle cover and the relevant valve are in a closed state;

[0032] S3. Heating process: start the power supply, connect the cooling water, start the refrigerant switch, and turn on the heating switch of the extraction kettle and the separation kettle, and set the temperatures of the extraction kettle and the separation kettle I, II, and III to 40°C and 55°C respectively. ℃, 45℃, 45℃;

[0033] S4. Boosting process: When the temperature of the refrigerator drops to 5.5°C, and the temperature of the extraction kettle and the separation kettle reaches ...

Embodiment 3

[0035] The method of embodiment 3 supercritical carbon dioxide extraction Ligustrum lucidum ursolic acid

[0036] S1, pretreatment: pulverize Ligustrum lucidum to 50 mesh for later use;

[0037] S2, feeding: take by weighing 200g of privet fruit powder pulverized in step S1, put it into the extraction kettle of the supercritical carbon dioxide extraction device, tighten the extraction kettle cover, and check whether the separation kettle cover and the relevant valve are in a closed state;

[0038] S3. Heating process: start the power supply, connect the cooling water, start the refrigerant switch, and turn on the heating switch of the extraction kettle and the separation kettle, and set the temperatures of the extraction kettle and the separation kettle I, II, and III to 55°C and 45°C respectively. ℃, 45℃, 45℃;

[0039]S4. Boosting process: When the temperature of the refrigerator drops to 6°C, and the temperature of the extraction kettle and the separation kettle reaches the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com