A kind of graphene/rubber composite material preparation method

A composite material and graphene technology, which is applied in the field of graphene/rubber composite material preparation, can solve the problems of graphene being difficult to disperse, deteriorated rubber properties, easy to agglomerate, etc., and achieves environmental friendliness, high preparation efficiency, and application prospects. expansive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

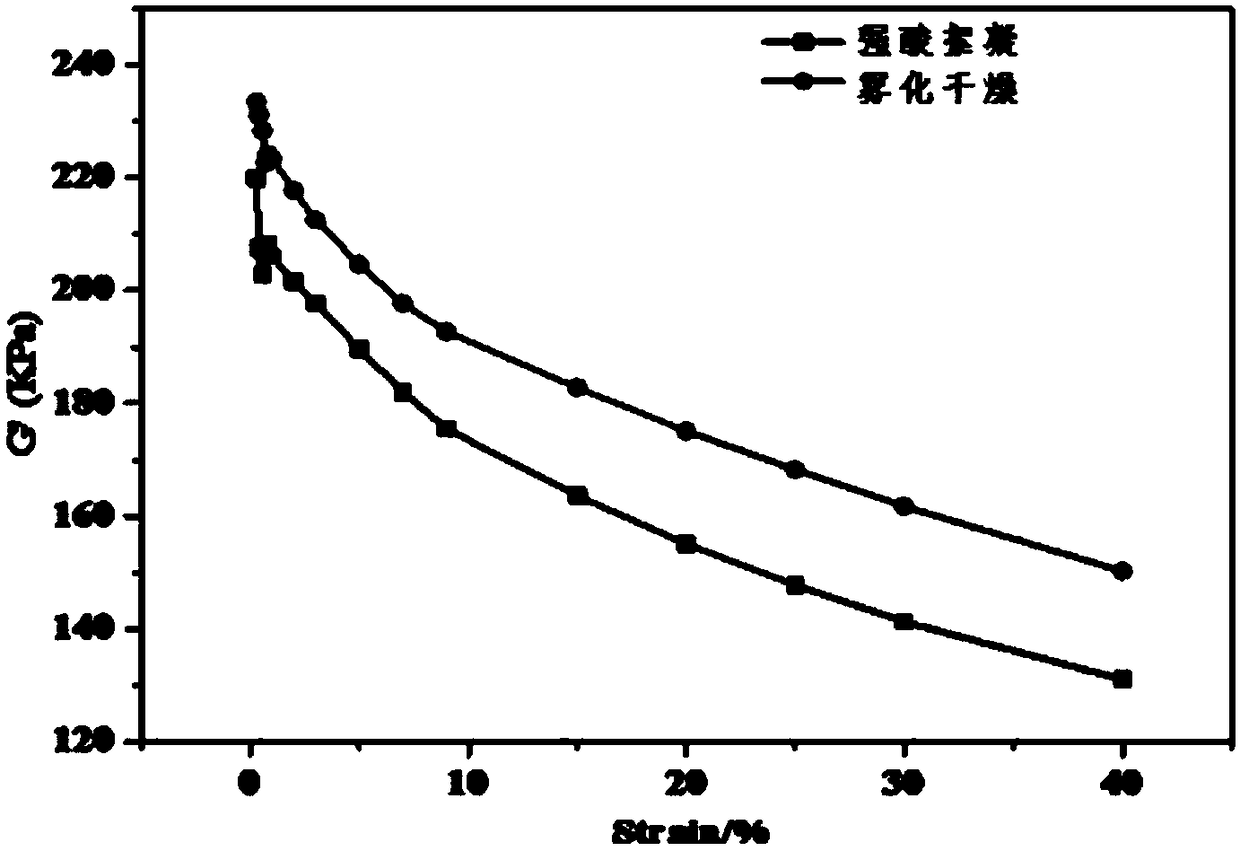

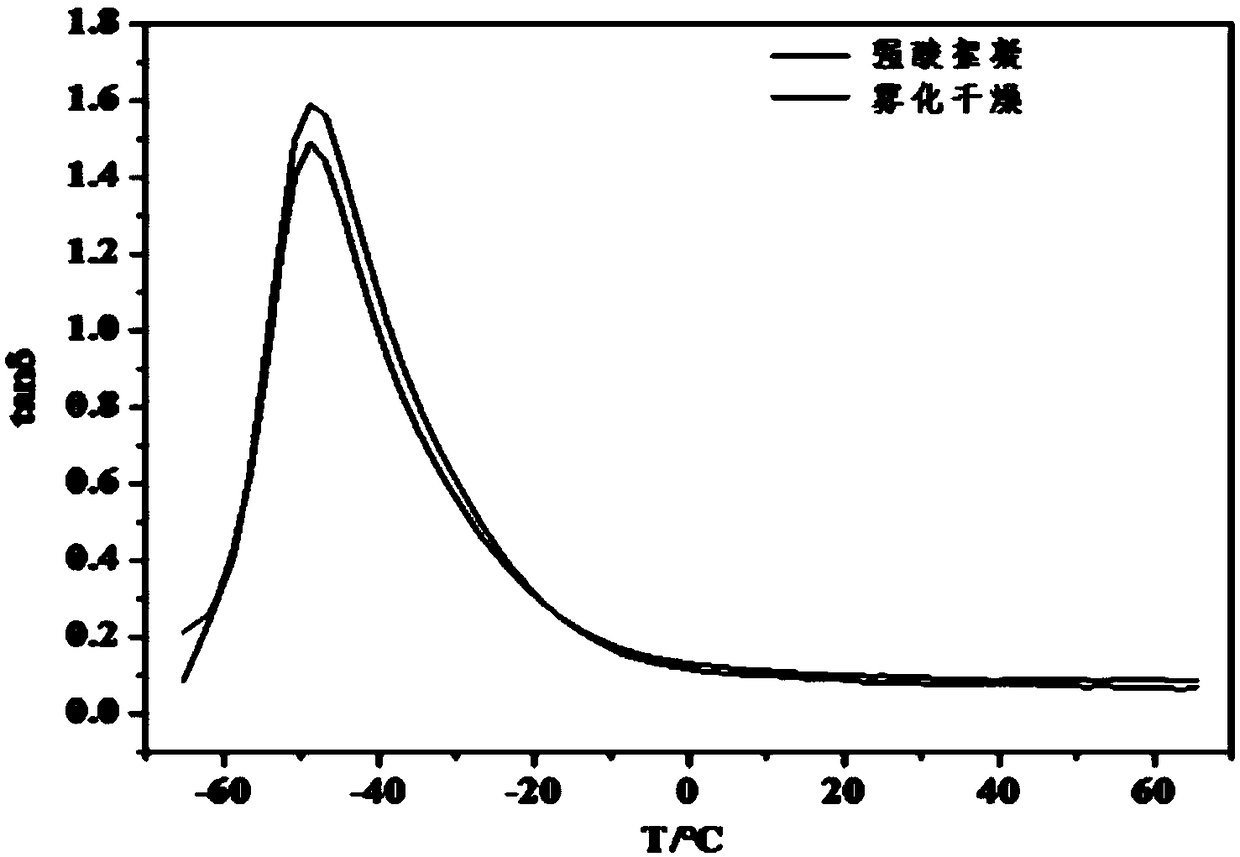

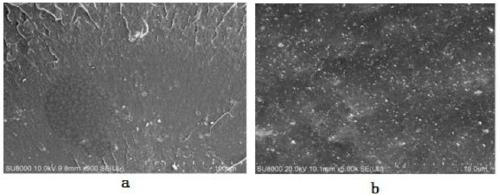

[0021]The preparation method of the silica / rubber composite material involved in this embodiment is also called the atomization drying method, and its process includes three steps of preparing the masterbatch mixture, preparing the masterbatch and preparing the composite material:

[0022] (1) Preparation of masterbatch mixture: first prepare modified graphene oxide aqueous solution: graphene oxide powder and water are ultrasonicated for 15min-12h at a temperature of 25-100°C and a power of 500-1500W to prepare graphene oxide Aqueous solution, the content of graphene oxide in the graphene oxide aqueous solution is 1-10mg / ml, adding γ-aminopropyltriethoxysilane (KH-550) to the deionized water of set quality and diluting to a mass percentage concentration of 0.5-2% KH-550 aqueous solution, add graphene oxide aqueous solution to KH-550 aqueous solution to form a mixed solution, ultrasonically disperse the mixed solution at room temperature for 10-30min, and then place the mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com