Method for preparing higher fatty acid alkali salt

A technology of higher fatty acid and alkaline earth metal, which is applied in the preparation of calcium salt, strontium salt, and the field of higher fatty acid magnesium salt, can solve the problem of no clear description, and achieve the effect of saving energy, simple equipment and ensuring energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

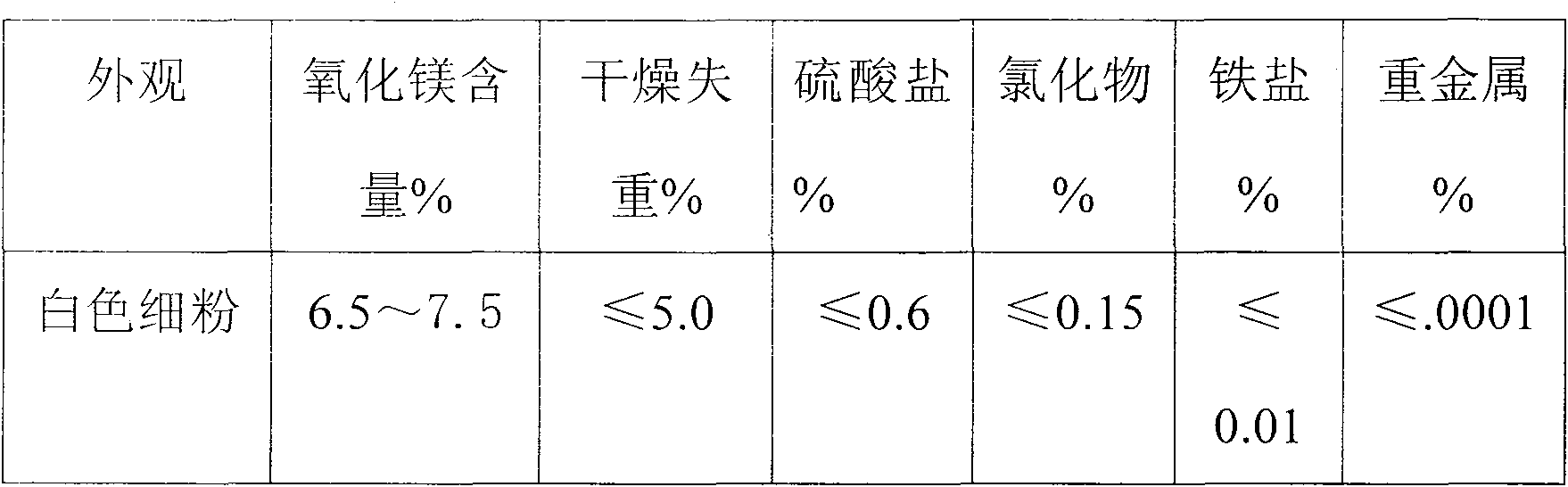

[0020] Embodiment 1: the preparation method of magnesium stearate

[0021] 100 kilograms of stearic acid (acid value 210), heated to 80 DEG C, added 8.2 kilograms of magnesium oxide (96%) micropowder, premixed, dispersed, and then preheated to 80 DEG C containing catalyst (acetic acid 0.06kg), moistening Wet agent (sodium lauryl sulfate 0.12kg) aqueous solution 20kg, continuously fed into the high-speed mixer that can control the premixing time, the premixing time is about 20 seconds, and then continuously output to the heat preservation machine that has been preheated to 80-90°C In the tank, keep warm for 2 hours, and after pulverization, the target product can be obtained. Its quality indicators are: magnesium oxide content 7.5%, free acid ≤ 1%, heating loss ≤ 3%, melting point ≥ 120°C, fineness ≤ 75μm.

[0022] Note: The stearic acid (acid value 210) used in this example is a mixed acid with a hexadecanoic acid content of 60% and an octadecanoic acid content of 40%, so the...

Embodiment 2

[0023]Embodiment 2: the preparation method of magnesium stearate

[0024] Stearic acid (acid value 210) 100 kilograms, is heated to 80 ℃, adds 11.5 kilograms of magnesium hydroxide (98%) micropowders, premixes, disperses, and then preheats to 80 ℃ containing catalyst (hydrogen peroxide 0.2kg), Wetting agent (potassium laurate 0.12kg) aqueous solution 20kg, continuously fed into the high-speed mixer capable of controlling the premixing time, the premixing time is about 15 seconds, and then continuously output to the insulation tank that has been preheated to 80-90°C , kept warm for 2 hours, and after pulverization, the target product was obtained. Its quality indicators are: magnesium oxide content 7.5%, free acid ≤ 1%, heating loss ≤ 3%, melting point ≥ 120°C, fineness ≤ 75μm.

Embodiment 3

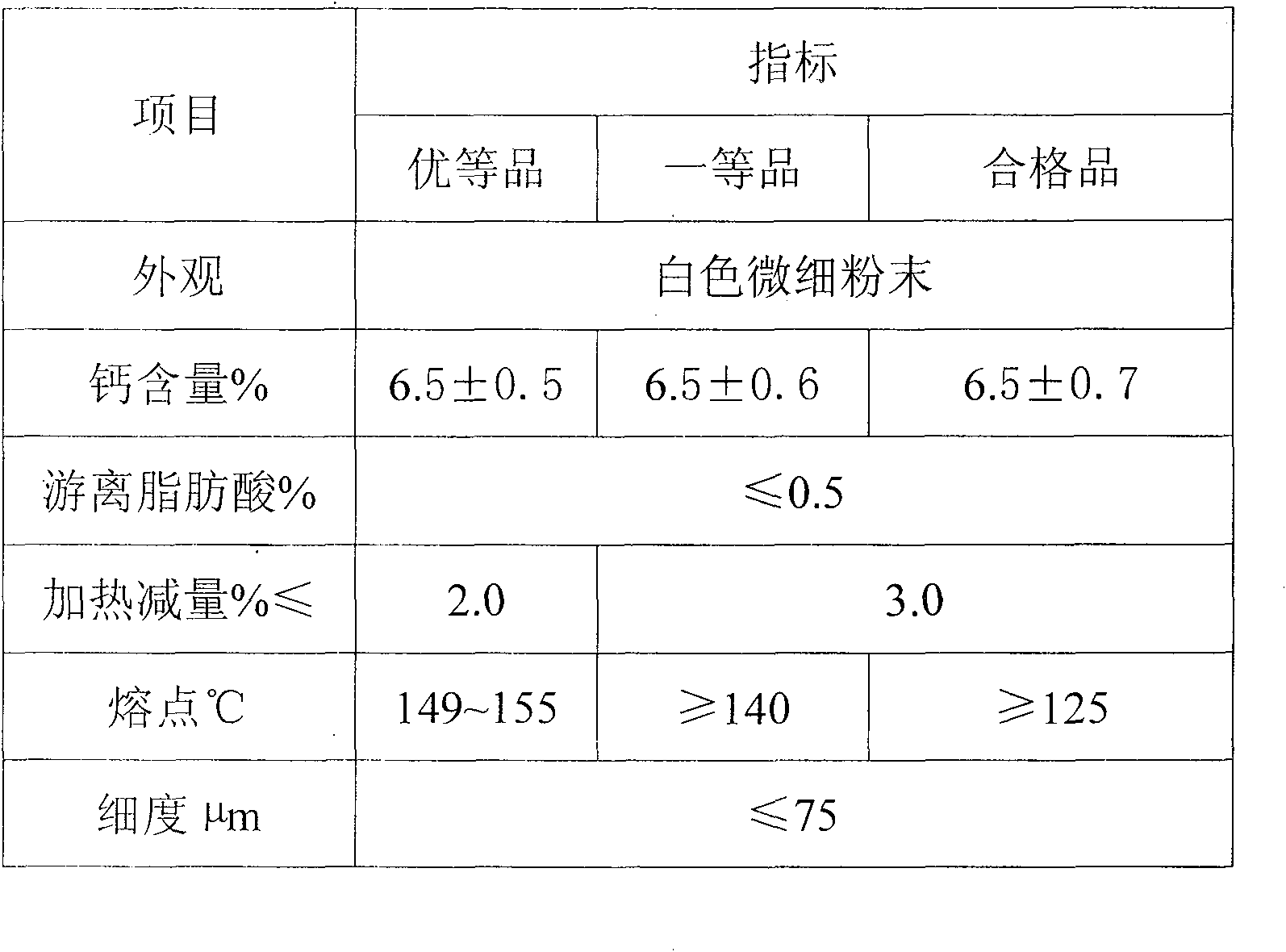

[0025] Embodiment 3: the preparation method of calcium stearate

[0026] Stearic acid (acid value 210) 100 kilograms, is heated to 75 ℃, adds 12.1 kilograms of calcium oxide (89%) micropowders, premixes, disperses, and then preheats to 80 ℃ containing catalyst (p-toluenesulfonic acid 0.04kg), wetting agent (20kg of aqueous solution of diisooctyl alcohol succinate sodium sulfonate 0.06kg), continuously feed into the high-speed mixer that can control the premixing time, the premixing time is about 15 seconds, and then continuously output to Preheated to 80 ~ 90 ℃ insulation tank, heat preservation for 2 hours, after pulverization, the target product can be obtained. Its quality indicators are: calcium content 7.0%, free acid ≤ 1%, heating loss ≤ 3%, melting point ≥ 150°C, fineness ≤ 75μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com