A preparation method of silicon-aluminum composite abrasive for sapphire substrate polishing

A sapphire substrate, composite abrasive technology, applied in polishing compositions containing abrasives, chemical instruments and methods, other chemical processes, etc., can solve the problem that the scratch of alumina particles cannot be effectively suppressed, and the redispersion of composite abrasive particles is difficult to maintain. , is not conducive to large-scale production and other problems, to achieve the effect of avoiding the mixing of alumina, high surface quality characteristics, and enhancing dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

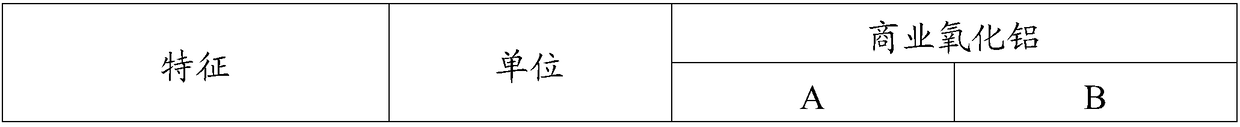

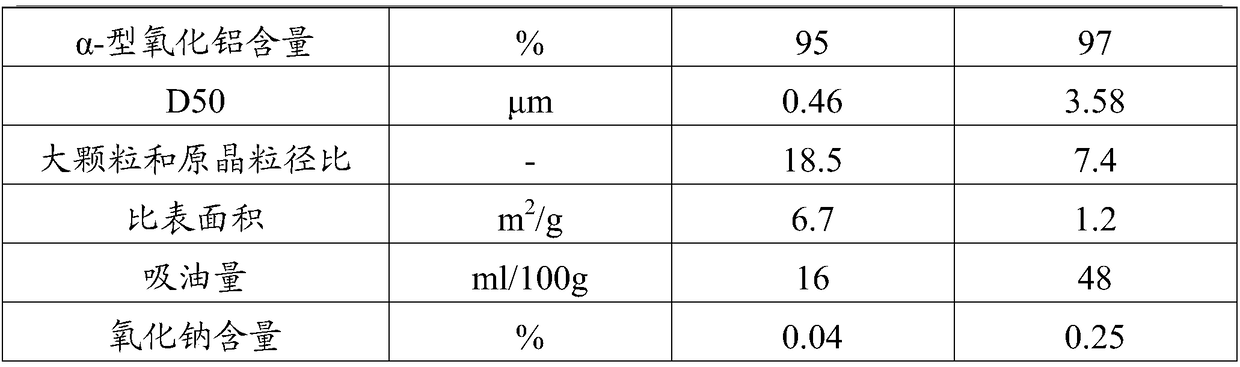

Embodiment 1

[0018] 1g of aminopropyltriethoxysilane and 100g of commercial alumina powder A in Table 1 were uniformly dispersed in 1000g of water solvent successively, and the pH value of the dispersion was adjusted by using a sodium hydroxide (NaOH) solution with a concentration of 1wt.%. After adjusting to 9.5, the dispersion was heated to 100°C. Keep the temperature at 100°C constant, add 800ml of pre-prepared orthosilicic acid (the concentration of silicon oxide is 3wt.%) to the suspension of alumina powder at a rate of 2ml / min, and at the same time, add it at a rate of 0.05ml / min. The NaOH solution with a concentration of 1 wt.% was continuously supplemented to maintain the pH value of the reaction system at 9-10. Continue to keep warm for 30 minutes after feeding, then stop heating and cool to room temperature to prepare silicon-aluminum composite abrasive with stable suspension and dispersion.

Embodiment 2

[0020]3g of mercaptopropyltrimethoxysilane and 200g of commercial alumina powder A in Table 1 were uniformly dispersed successively in 1000g of water solvent, and the pH value of the dispersion was adjusted to 10.0 with a concentration of 5wt.% ammonia solution and then heated. Dispersion to 95°C. Keep the temperature at 95°C constant, add 800ml of pre-prepared orthosilicic acid (silicon oxide concentration: 4wt.%) to the suspension of alumina powder at a rate of 4ml / min, and at the same time, add it at a rate of 0.05ml / min. The ethylenediamine solution with a concentration of 1 wt.% was continuously supplemented to maintain the pH value of the reaction system at 9-10. Continue to keep warm for 30 minutes after feeding, then stop heating and cool to room temperature to prepare silicon-aluminum composite abrasive with stable suspension and dispersion.

Embodiment 3

[0022] 5g of mercaptopropyltrimethoxysilane and 5g of sulfopropyltriethoxysilane and 100g of commercial alumina powder B in Table 1 were uniformly dispersed in 1000g of water solvent successively, and the acetic acid solution with a concentration of 1wt.% was used to dissolve After adjusting the pH of the dispersion to 9.0, the dispersion was heated to 100°C. Keep the temperature at 100°C constant, add 2000ml of pre-prepared orthosilicic acid (silicon oxide concentration: 5wt.%) to the suspension of alumina powder at a rate of 4ml / min, and at the same time, add 0.05ml / min The rate is to continuously replenish the triethanolamine solution with a concentration of 2wt.% to maintain the pH value of the reaction system at 9-10. Continue to keep warm for 30 minutes after feeding, then stop heating and cool to room temperature to prepare silicon-aluminum composite abrasive with stable suspension and dispersion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com