Heat treatment method for adjusting alpha-beta-phase titanium alloy texture

A heat treatment method and titanium alloy technology, which is applied in the field of titanium alloy processing, can solve the problems of many influencing factors, and achieve the effect of simple parameters, improved stability, and small influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Lamellar tissue transforms into spherical tissue after heat treatment:

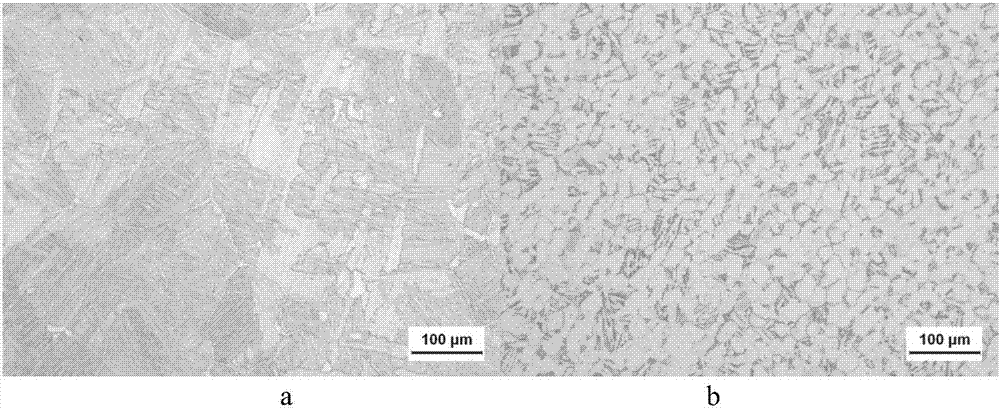

[0034] The material uses TC4 titanium alloy rod with a diameter of 210mm. The phase transition point is 990°C measured by metallographic method. figure 1 as shown in a.

[0035] Step 1: Use a resistance heat treatment furnace with a heat preservation uniformity of less than or equal to ±15°C in the effective heating zone, and raise the temperature to 840°C (150°C below the phase transition point);

[0036] Step 2: Put the bar into the effective area of the heat treatment furnace. At this time, the furnace temperature will drop to about 700°C. When the furnace temperature rises to 840°C, start to calculate the holding time;

[0037] Step 3: The total holding time is set to 30 hours. After the holding time reaches the requirement, it can be released from the oven, and the bar is air-cooled at room temperature.

[0038] Sampling and checking the structure of the bar, and comparing the structure of...

Embodiment 2

[0040] The lamellar structure transforms into a two-state structure after heat treatment:

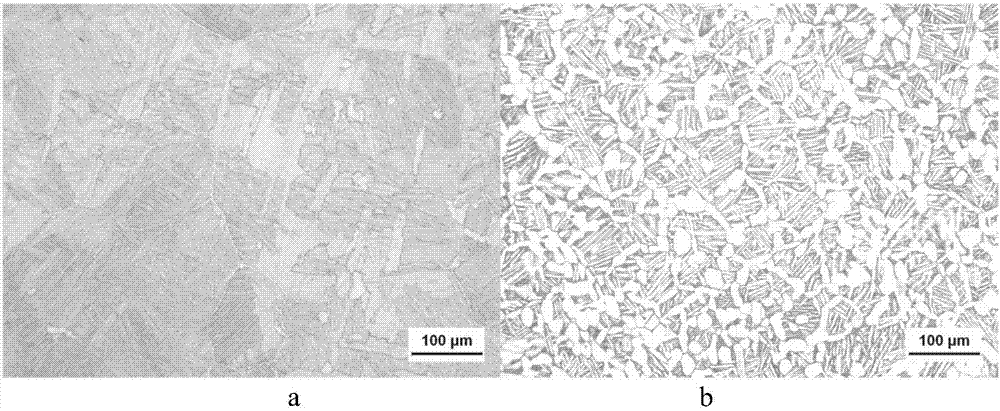

[0041] The material uses TC4 titanium alloy rod with a diameter of 210mm. The phase transition point is 990°C measured by metallographic method. figure 2 as shown in a.

[0042] Step 1: Use a resistance heat treatment furnace with a heat preservation uniformity of less than or equal to ±15°C in the effective heating zone, and raise the temperature to 960°C (30°C below the phase transition point);

[0043] Step 2: Put the bar into the effective area of the heat treatment furnace. At this time, the furnace temperature will drop to about 800°C, and the holding time will be calculated when the furnace temperature rises to 960°C again;

[0044] Step 3: The total holding time is set to 10 hours. After the holding time reaches the requirement, it can be released from the oven, and the bar is air-cooled at room temperature.

[0045] Sampling and checking the structure of the bar, the struc...

Embodiment 3

[0047] After heat treatment, the spherical structure transforms into a two-state structure:

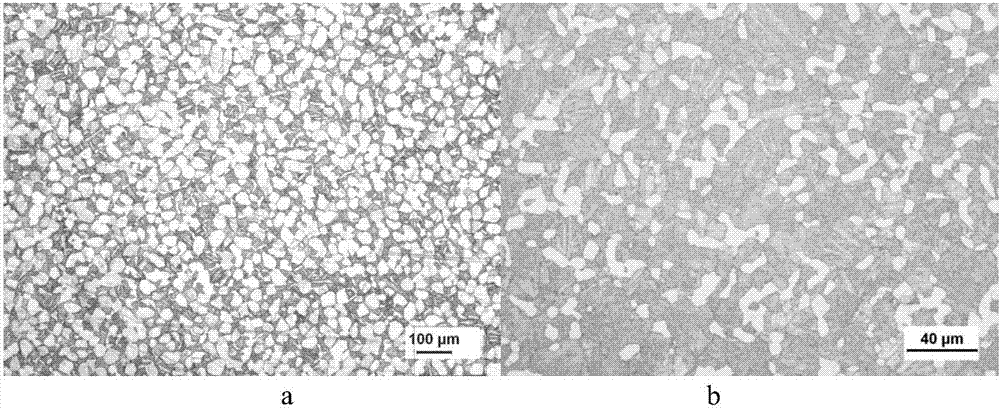

[0048] The material is TC4 titanium alloy bar with a diameter of 210mm. The phase transition point is 990°C measured by metallographic method. The bar is obtained by forging the ingot through multiple fires below the phase transition point. image 3 as shown in a.

[0049] Step 1: Use a resistance heat treatment furnace with a heat preservation uniformity of less than or equal to ±15°C in the effective heating zone, and raise the temperature to 970°C (20°C below the phase transition point);

[0050] Step 2: Put the bar into the effective area of the heat treatment furnace. At this time, the furnace temperature will drop to about 800°C. When the furnace temperature rises to 970°C, start to calculate the holding time;

[0051] Step 3: The total holding time is set to 3 hours. After the holding time reaches the requirement, it can be released from the oven, and the bar is air-cooled a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com