Method for removing carbonate in cyanide silver-plating bath solution

A carbonate and silver-plating tank technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of severe heat release, large safety hazards, etc., and achieve the effect of less environmental pollution, less safety hazards, and less volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Get a volume and be 100L sodium cyanide silver-plating bath solution, measure Na in the cyanide silver-plating bath solution by chemical analysis 2 CO 3 .10H 2 The O content is 259.6g / L, and now it is planned to 2 CO 3 .10H 2 O content reduced to 50g / L, according to CaCl 2 with Na 2 CO 3 .10H 2 The chemical reaction equation of O:

[0033] CaCl 2 +Na 2 CO 3 .10H 2 O→CaCO 3 ↓+2NaCl+10H 2 o

[0034] Calculate the need to add CaCl 2 8.13Kg;

[0035] Accurately weigh 8.13Kg CaCl 2 , dissolved in water to give CaCl 2 Solution, join in the sodium cyanide silver-plating bath, stir evenly, after standing for 8h, adopt filtering device to filter the sodium cyanide silver-plating bath, adopt chemical analysis to detect Na in the cyanide silver-plating bath 2 CO 3 .10H 2 The O content was 50.3 g / L.

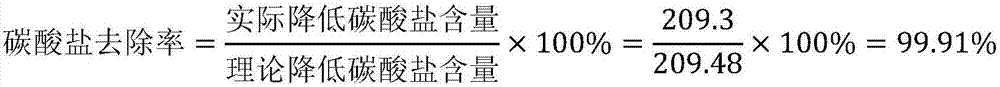

[0036] According to the above analysis results, it can be learned that adding 8.13Kg CaCl 2 actually reduce Na 2 CO 3 .10H 2The O content is 259.6g / L-50.3g / L...

Embodiment 2

[0040] With a volume of 100L sodium cyanide silver plating bath, measure Na in the cyanide silver plating bath by chemical analysis 2 CO 3 .10H 2 The O content is 259.6g / L, and now it is planned to use BaCl 2 2H 2 O's method converts Na 2 CO 3 .10H 2 O content reduced to 50g / L, according to BaCl 2 2H 2 O and Na 2 CO 3 .10H 2 The chemical reaction equation of O:

[0041] BaCl 2 2H 2 O+Na 2 CO 3 .10H 2 O → BaCO 3 ↓+2NaCl+12H 2 o

[0042] Calculate the need to add BaCl 2 2H 2 O is 17.88Kg;

[0043] Accurately weigh 17.88Kg BaCl 2 2H 2 O is directly added to the sodium cyanide silver-plating bath, stirred evenly, and after standing for 10 days, a filter device is used to filter the sodium cyanide silver-plating bath, and chemical analysis is used to detect Na in the cyanide silver-plating bath. 2 CO 3 .10H 2 The O content was 134.5 g / L.

[0044] According to the above analysis results, it can be learned that adding 17.88Kg BaCl 2 2H 2 O actually lowers...

Embodiment 3

[0047] With a volume of 100L potassium cyanide silver plating bath, K in the cyanide silver plating bath is measured by chemical analysis 2 CO 3 The content is 127.3g / L, now it is planned to add K 2 CO 3 The content is reduced to 40g / L, according to CaCl 2 with K 2 CO 3 The chemical reaction equation:

[0048] CaCl 2 +K 2 CO 3 →CaCO 3 ↓+2KCl

[0049] Calculate the need to add CaCl 2 7.02Kg;

[0050] Accurately weigh 7.02Kg CaCl 2 , dissolved in water to give CaCl 2 Solution, join in the sodium cyanide silver-plating bath, stir evenly, after standing for 8 hours, adopt filtering device to filter the sodium cyanide silver-plating bath, adopt chemical analysis to detect K in the cyanide silver-plating bath 2 CO 3 The content is 40.16g / L.

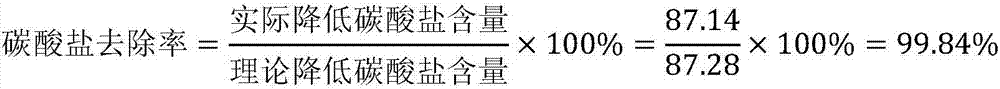

[0051] According to the above analysis results, it can be known that adding 7.02Kg CaCl 2 actually reduce K 2 CO 3 The content is 127.3g / L-40.16g / L=87.14g / L; according to CaCl 2 with K 2 CO 3 According to the chemical reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com