Heatproof aqueous treating agent for super black and super haze as well as preparation method thereof

A treatment agent and temperature-resistant technology, which is applied in the field of temperature-resistant water-based super black and special fog treatment agent and its preparation, can solve the problems such as difficult to form super black and special fog effect, achieve smooth hand feeling, increase cost, and clear color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

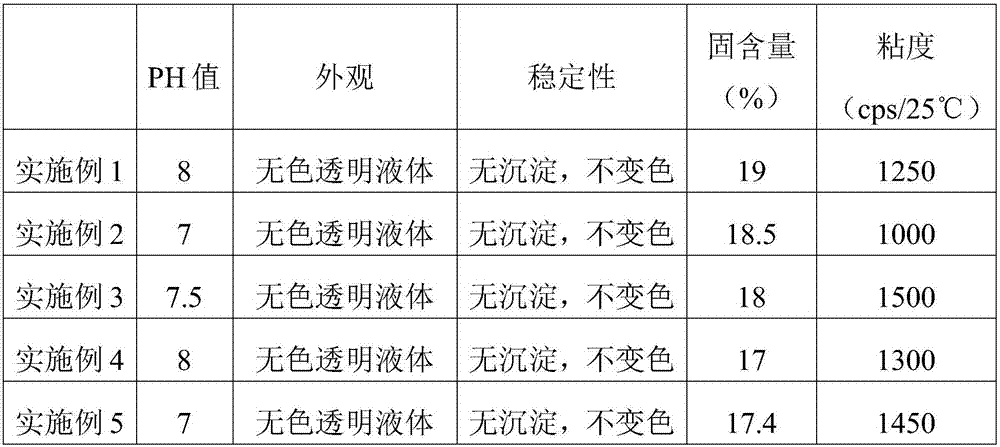

Examples

Embodiment 1

[0019] The temperature-resistant water-based ultra-black and special fog treatment agent is composed of the following components: 34.8kg temperature-resistant water-based polyurethane, 10.5kg butyl ether, 45kg water, 6.5kg silica matting powder, 1.25kg dispersant, 0.1kg Defoamer, 0.6kg wetting agent, 1.25kg thickener.

[0020] The preparation method of the temperature-resistant type water-based ultra-black special mist treatment agent of the embodiment of the present invention 1 comprises the following steps:

[0021] 1) Weigh each component material in proportion, mix 17.4kg of temperature-resistant water-based polyurethane, 10.5kg of butyl ether, 45kg of water, 6.5kg of silica matting powder, 1.25kg of dispersant, and 0.1kg of defoamer;

[0022] 2) Fully stir the mixture at a stirring speed of 1000r / min, and disperse for 30min;

[0023] 3) Add the remaining 17.4kg of temperature-resistant water-based polyurethane, 0.6kg of wetting agent, and 1.25kg of thickener into the mix...

Embodiment 2

[0026] The temperature-resistant water-based ultra-black and special fog treatment agent is composed of the following components: 33kg temperature-resistant water-based polyurethane, 11.5kg butyl ether, 50kg water, 5kg silica matting powder, 1.75kg dispersant, 0.12kg defoaming agent agent, 0.5kg wetting agent, 1.5kg thickener.

[0027] The preparation method of the temperature-resistant type water-based ultra-black special mist treatment agent of the embodiment of the present invention 2 comprises the following steps:

[0028] 1) Weigh each component material in proportion, mix 16.5kg of temperature-resistant water-based polyurethane, 11.5kg of butyl ether, 50kg of water, 5kg of silica matting powder, 1.75kg of dispersant, and 0.12kg of defoamer;

[0029] 2) Fully stir the mixture at a stirring speed of 1000r / min, and disperse for 50min;

[0030] 3) Add the remaining 16.5kg of temperature-resistant water-based polyurethane, 0.5kg of wetting agent, and 1.5kg of thickener into ...

Embodiment 3

[0033] The temperature-resistant water-based ultra-black and special fog treatment agent is composed of the following components: 35kg temperature-resistant water-based polyurethane, 10kg butyl ether, 42kg water, 6kg silica matting powder, 1kg dispersant, 0.2kg defoamer, 0.8kg wetting agent, 1kg thickening agent.

[0034] The preparation method of the temperature-resistant type water-based special black special mist treatment agent of the embodiment of the present invention 3 comprises the following steps:

[0035] 1) Weigh each component material in proportion, mix 17.5kg of temperature-resistant water-based polyurethane, 10kg of butyl ether, 42kg of water, 6kg of silica matting powder, 1kg of dispersant, and 0.2kg of defoamer;

[0036] 2) Fully stir the mixture at a stirring speed of 1000r / min, and disperse for 60min;

[0037] 3) Add the remaining 17.5kg of temperature-resistant water-based polyurethane, 0.8kg of wetting agent, and 1kg of thickener into the mixture, and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com