Micro diaphragm pump upper end cover

A technology of micro-diaphragm pumps and end caps, applied to pumps, pump components, variable-capacity pump components, etc., can solve the problems of complex structure, troublesome assembly, and many parts, and achieve small volume, convenient assembly, and few parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

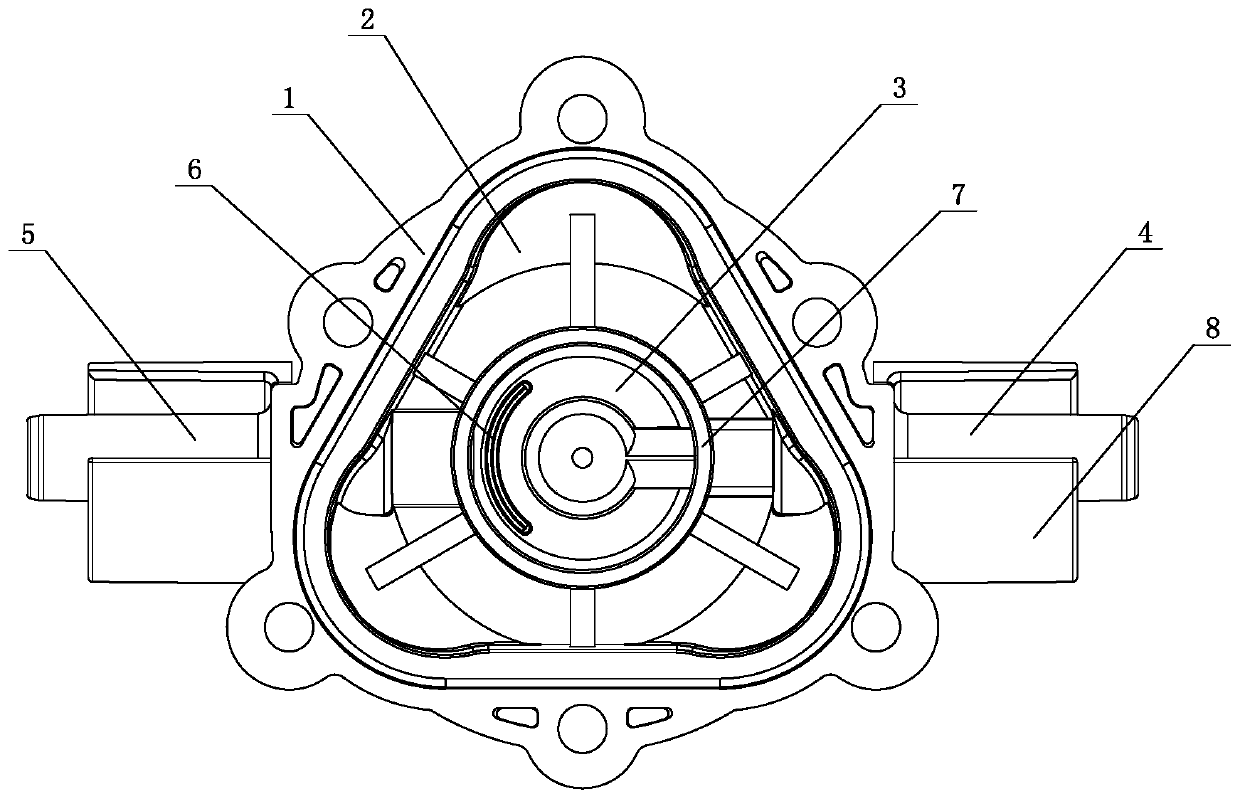

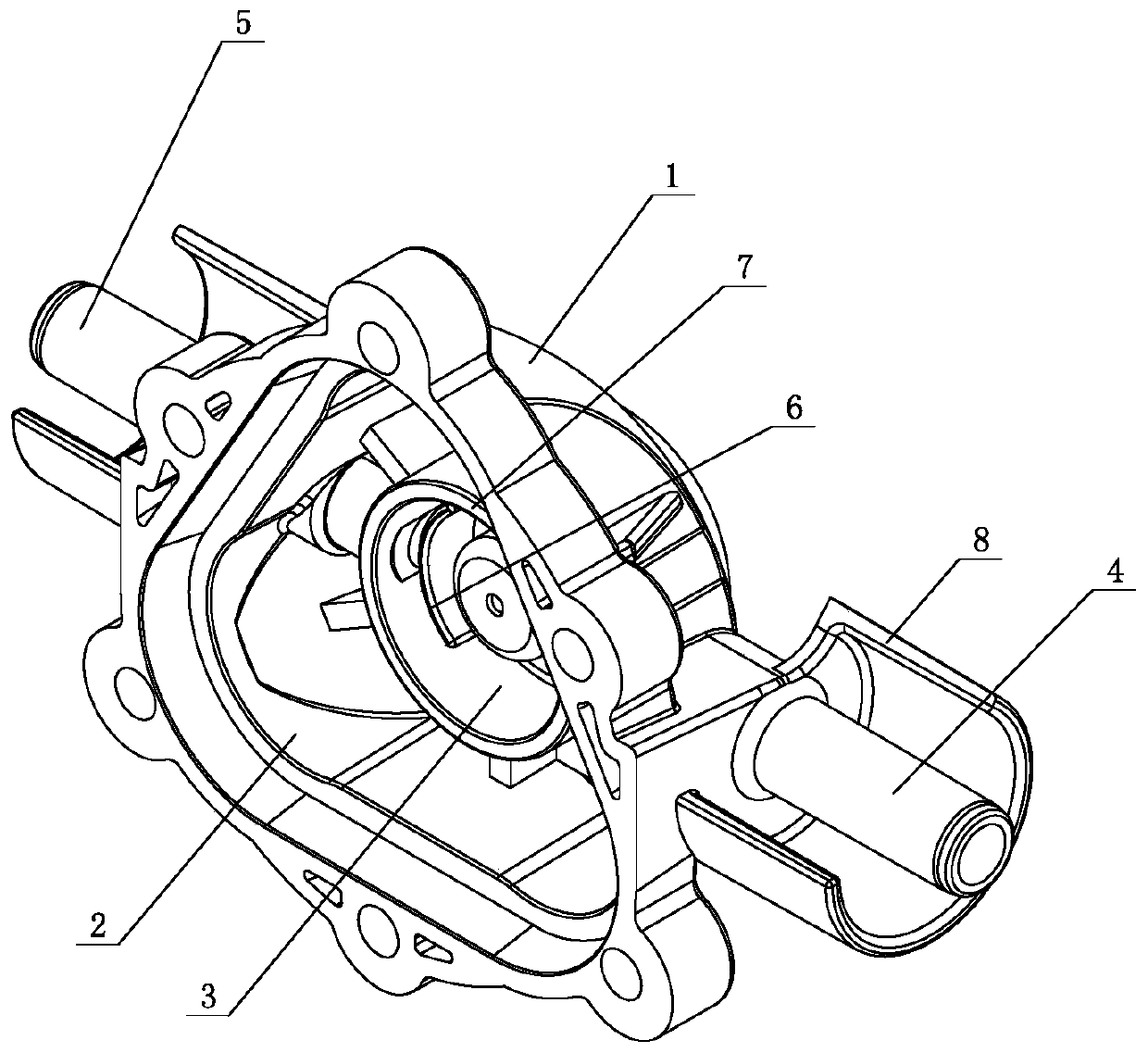

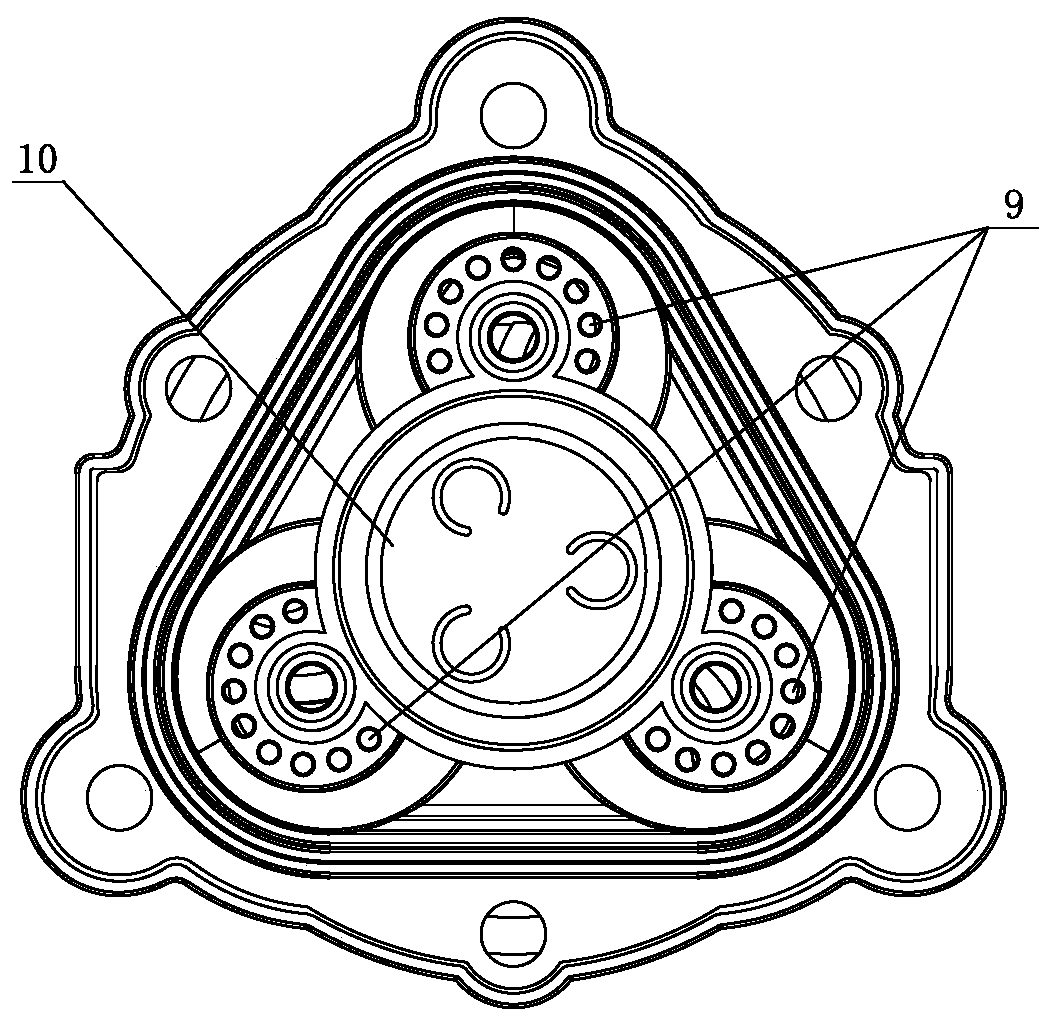

[0022] Such as figure 1 and figure 2 Shown, a kind of micro-diaphragm pump upper end cover, it comprises the cover body 1 that covers on the micro-diaphragm pump head, and the micro-diaphragm pump head that cover body 1 covers (seeing image 3 ) position, the head of the micro-diaphragm pump is provided with a water inlet 9 and a water outlet 10, and the water inlet 9 and the water outlet 10 are provided with a one-way valve plate, and the cover body 1 is provided with a water inlet chamber 2 and a water outlet chamber 3, and the two sides of the cover body 1 are respectively provided with a water inlet pipe 4 and a water outlet pipe 5, the water inlet pipe 4 communicates with the water inlet chamber 2, the water outlet pipe 5 communicates with the water outlet chamber 3, and the water outlet chamber 3 is provided with The water baffle 6 prevents the outlet water from the water outlet 10 of the head of the micro-diaphragm pump from directly entering the outlet pipe 5 . The ...

Embodiment 2

[0030] A kind of micro-diaphragm pump upper end cover, it comprises the cover body 1 that covers on the micro-diaphragm pump head, and the micro-diaphragm pump head that cover body 1 covers (see image 3 ) position, the head of the micro-diaphragm pump is provided with a water inlet 9 and a water outlet 10, and the water inlet 9 and the water outlet 10 are provided with a one-way valve plate, and the cover body 1 is provided with a water inlet chamber 2 and a water outlet chamber 3, and the two sides of the cover body 1 are respectively provided with a water inlet pipe 4 and a water outlet pipe 5, the water inlet pipe 4 communicates with the water inlet chamber 2, the water outlet pipe 5 communicates with the water outlet chamber 3, and the water outlet chamber 3 is provided with The water baffle 6 prevents the outlet water from the water outlet 10 of the head of the micro-diaphragm pump from directly entering the outlet pipe 5 . The water inlet 9 of the head of the micro-diap...

Embodiment 3

[0033] A kind of micro-diaphragm pump upper end cover, it comprises the cover body 1 that covers on the micro-diaphragm pump head, and the micro-diaphragm pump head that cover body 1 covers (see image 3) position, the head of the micro-diaphragm pump is provided with a water inlet 9 and a water outlet 10, and the water inlet 9 and the water outlet 10 are provided with a one-way valve plate, and the cover body 1 is provided with a water inlet chamber 2 and a water outlet chamber 3, and the two sides of the cover body 1 are respectively provided with a water inlet pipe 4 and a water outlet pipe 5, the water inlet pipe 4 communicates with the water inlet chamber 2, the water outlet pipe 5 communicates with the water outlet chamber 3, and the water outlet chamber 3 is provided with The water baffle 6 prevents the outlet water from the water outlet 10 of the head of the micro-diaphragm pump from directly entering the outlet pipe 5 . The water inlet 9 of the head of the micro-diaph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com