Automatic clutch gear shifting arm assembly, engine and motorcycle

A technology of automatic clutch and shift arm, which is applied in the direction of mechanical equipment, components with teeth, transmission device control, etc., can solve the problems of poor reliability of parts strength, unreliable guidance, accelerated wear, etc., to improve accuracy and stability performance, ensure guiding accuracy, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

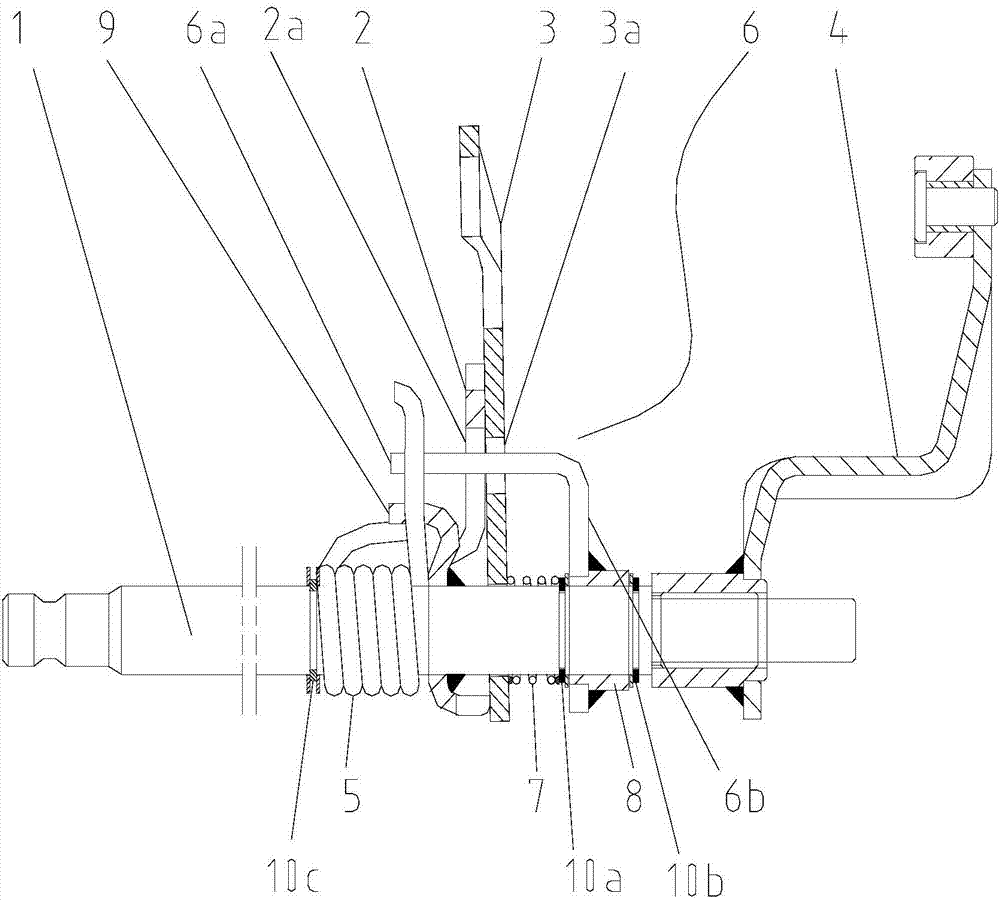

[0017] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the automatic clutch shift arm assembly in this embodiment; includes a shift shaft 1, a limit plate 2, a shift plate 3, a clutch control arm 4 and is used to make the shift shaft 1 Return torsion spring 5 to return to the position; the shift plate 3 is movably overlaid on the shift shaft 1 and axially pressed against the limit plate 2 fixed on the shift shaft 1 under the action of an elastic force, the clutch operates The arm 4 is fixedly arranged on the shift shaft 1 along the circumferential direction, and the shift shaft 1 realizes shifting by driving the shift plate 3 to rotate in a manner that the rotation lags behind the clutch control arm 4; 6, the guide 6 slides and guides the shifting plate 3 in the axial direction; the elastic force can be provided by a cylindrical spring 7 that is outside the shift shaft 1, and the cylindrical spring 7 is located between the shifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com