Phase-change heat pipe with high reliability and high heat transfer performance

A reliable and high heat transfer technology, applied in the direction of heat storage equipment, heat exchange equipment, heat exchanger types, etc., can solve the problems that have not yet collected data, no explanation or report found, etc., and achieve good isothermal performance and weight index Small, highly reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

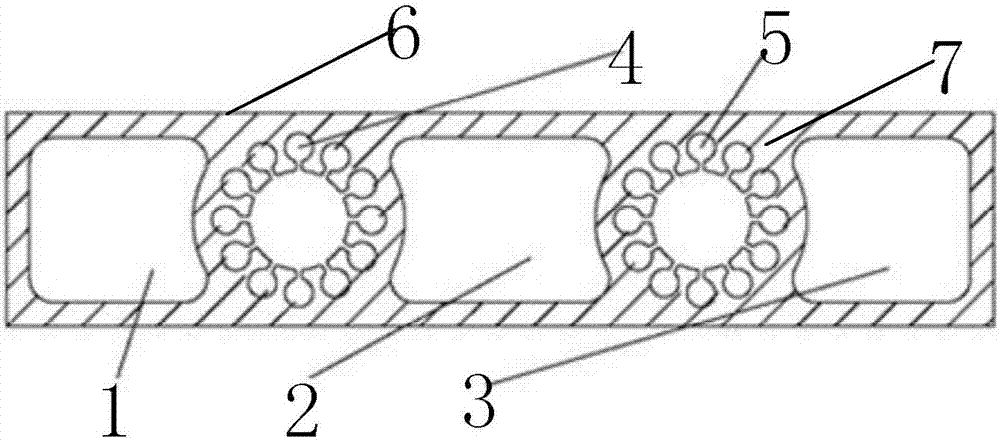

Image

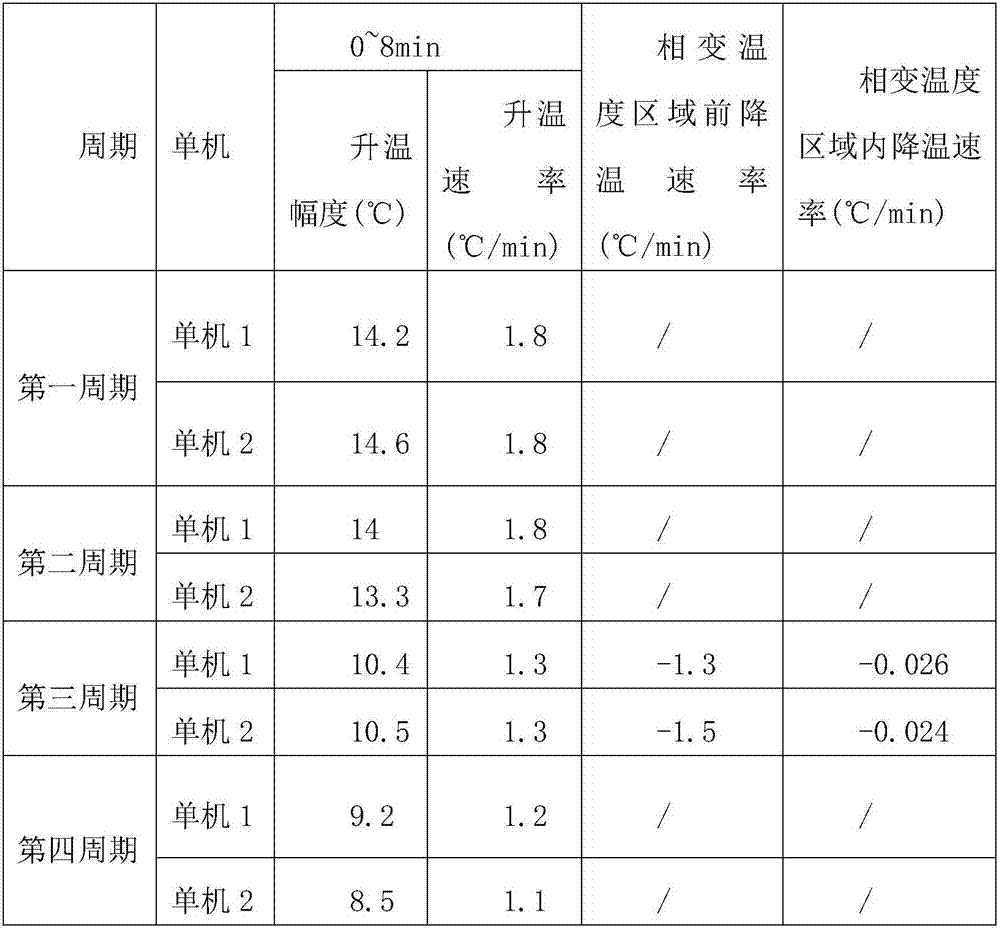

Examples

Embodiment 1

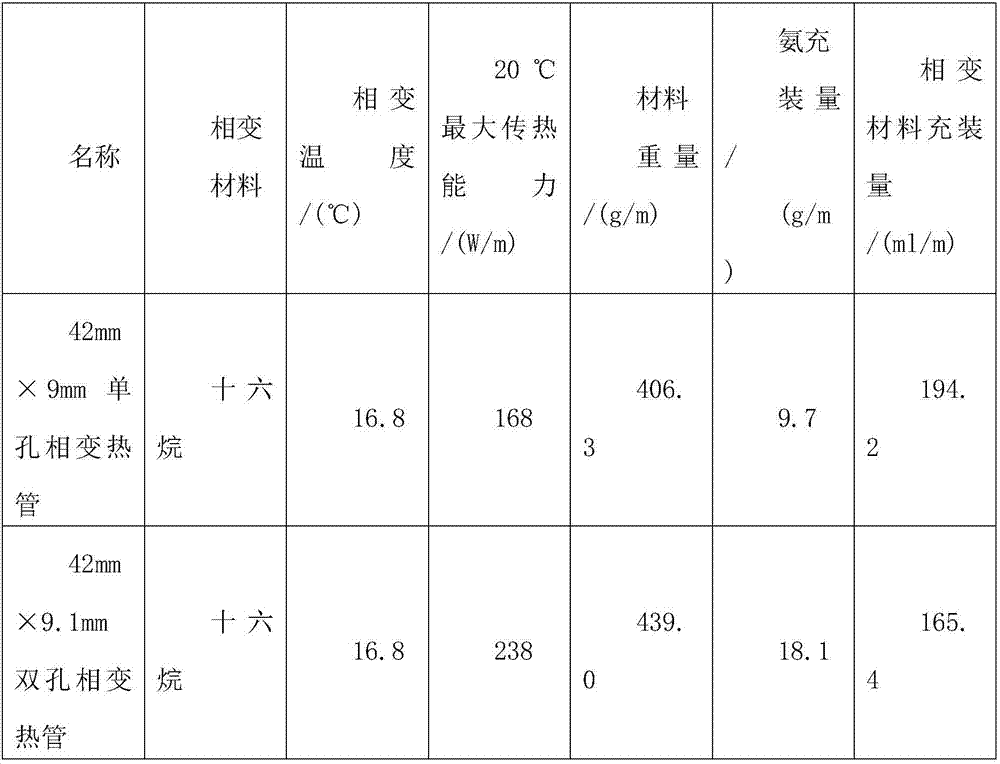

[0026] The phase-change heat pipe body of this embodiment is high-purity ammonia, and the phase-change material is hexadecane (the phase-change heat pipe body is 700mm, and the filling length of the phase-change material is 670mm). The relevant data of the calculation and test are shown in Table 1. .

[0027] Table 1

[0028]

[0029] As shown in Table 1, the 42mm×9.1mm double-hole phase-change heat pipe body has almost no change in external dimensions and only 8% increase in weight compared with the single-hole phase-change heat pipe body, and the maximum heat transfer capacity at 20°C has increased. 41.7%, the heat transfer capacity of the double-hole phase change heat pipe body is significantly improved.

[0030] The reliability calculation of the phase-change heat pipe body of the present invention shows that the basic failure rate of the phase-change heat pipe body is 100 fit. According to the requirement that the on-orbit operating life of the heat pipe is ≥ 5 years,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com