Blasting method of through oblique-pulling truss girder bridge

A cable-stayed and truss technology, which is applied in blasting, bridges, bridge construction, etc., can solve problems such as the impact on navigation, and achieve the effects of shortening the construction period, reducing impact, and reducing the degree of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to further illustrate the technical means adopted by the present invention and its effects, the following is a detailed description in conjunction with preferred embodiments of the present invention.

[0039] A method for blasting a cable-stayed truss girder bridge, the blasting method is divided into the following steps:

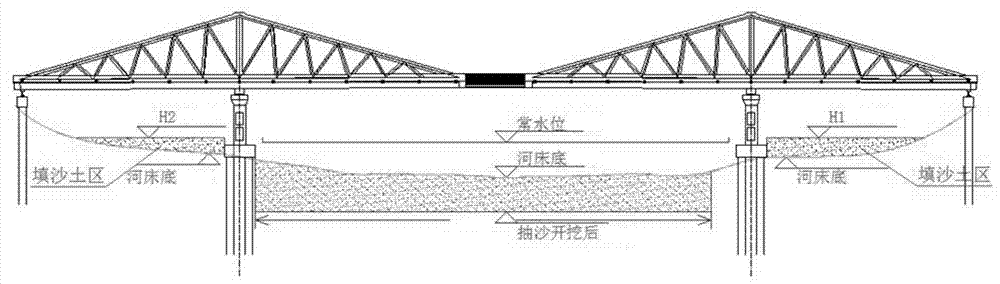

[0040] Step 1. Filling of the river: fill the two sides of the bridge towards the center of the river, the height of the filling is 1m higher than the normal water level, and the filling is perpendicular to the direction of the river to the edge of the bridge cap, and the width of the filling is determined according to the actual situation, such as figure 1 shown;

[0041] Step 2. Cleaning up the range of the river course: build construction access roads on both sides of the bridge, use dredgers to clear the silt at the bottom of the canal, and excavate a trench with a certain width between the two piers in the river channel, at least 5 mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com