Wellhead gas-liquid two-phase flow metering method and device

A gas-liquid two-phase flow and flow metering technology, which is applied in measuring devices, measuring flow/mass flow, liquid/fluid solid measurement, etc., can solve problems such as fluid disturbance, short maintenance cycle, instability, etc., and achieve improved stability and accuracy, increase compensation algorithm, and improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, further illustrate the present invention with embodiment. But this embodiment is only illustrative, and the protection scope of the present invention is not limited by this embodiment.

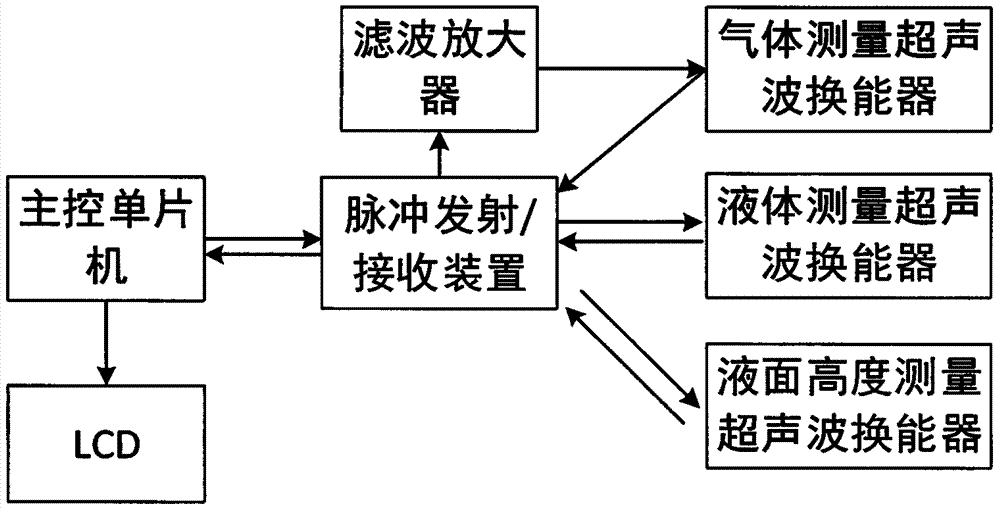

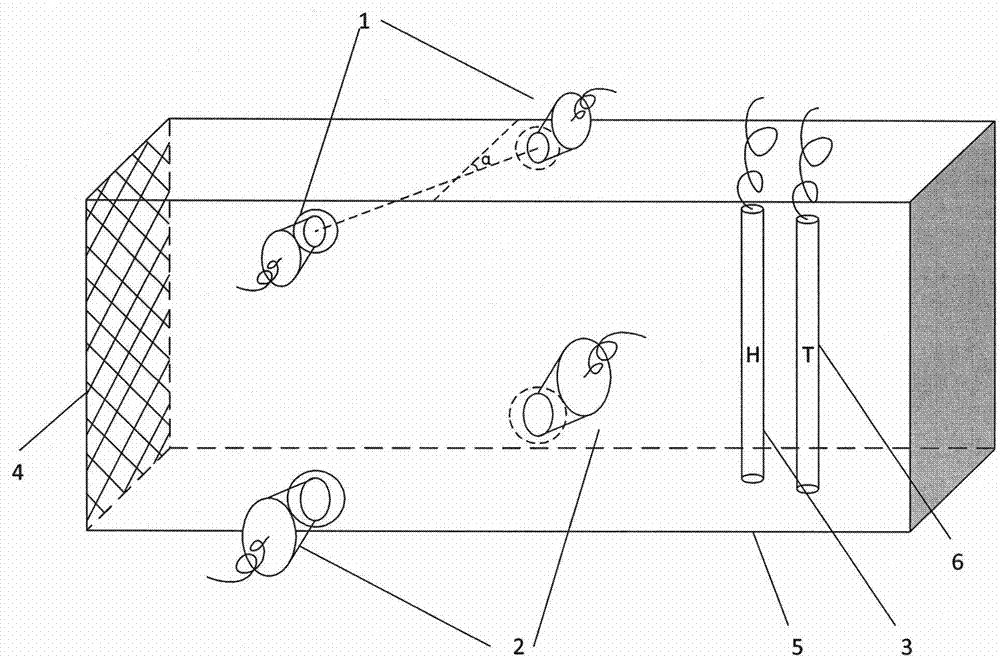

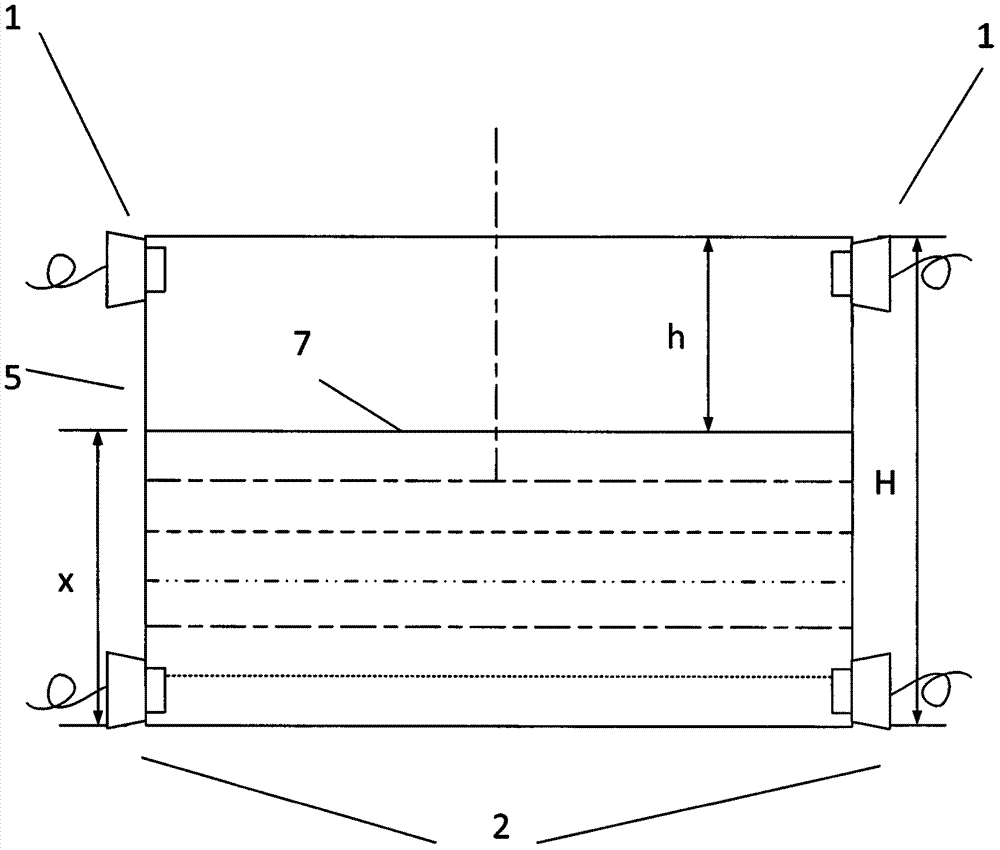

[0031] The method of the present invention is that 2 sets or more than 2 sets of ultrasonic transducer devices integrating transceiver functions are installed on the pipeline wall of the gas-liquid two-phase flow; the ultrasonic transducer emits ultrasonic pulses into the gas-liquid two-phase flow, and the The set of transducers is used to measure the flow velocity of gas and liquid in the gas-liquid two-phase flow at the wellhead. There is an included angle between the emitted ultrasonic pulse direction and the fluid direction, generally 45 degrees; these two sets of ultrasonic transducer devices emit ultrasonic waves Start the timer at the same time as the pulse, and stop timing when the receiving end receives the pulse, thus obtaining a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com