Track inspection system host

A technology of patrol inspection system and main engine, which is applied in the direction of data processing power supply, instrument, electrical digital data processing, etc. It can solve the problems of low work efficiency, heavy workload, inability to meet the requirements of railway fine inspection and timely and accurate maintenance and repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described below in conjunction with the drawings.

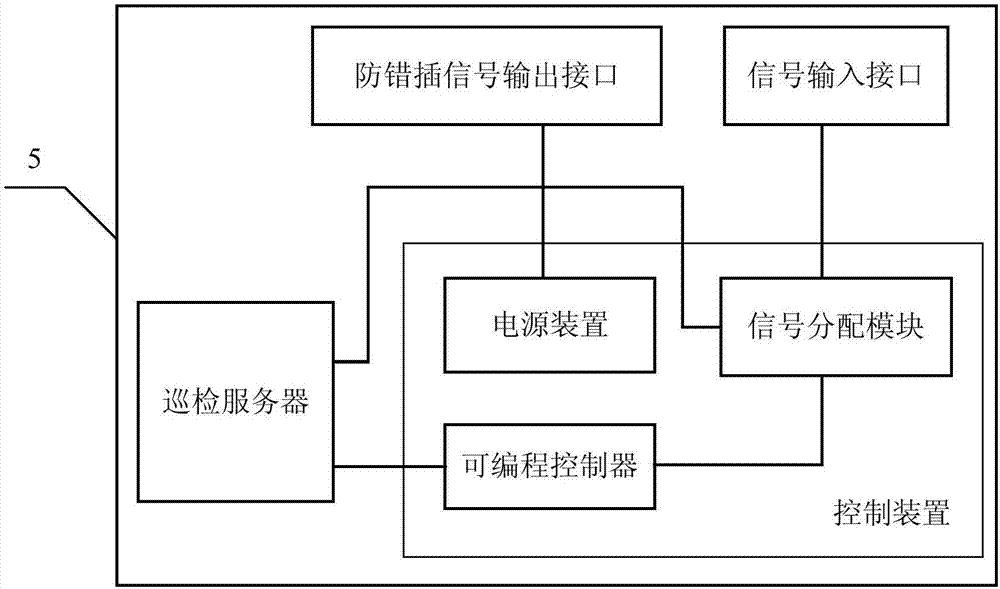

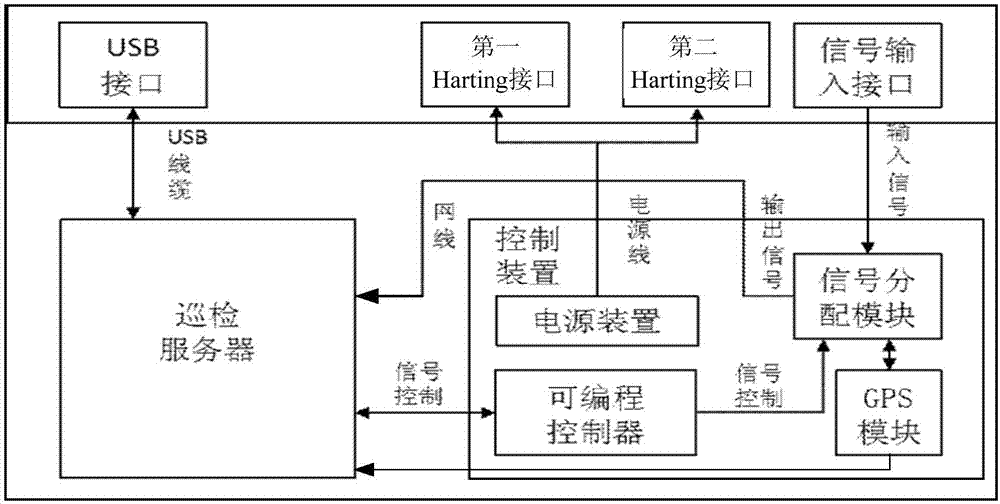

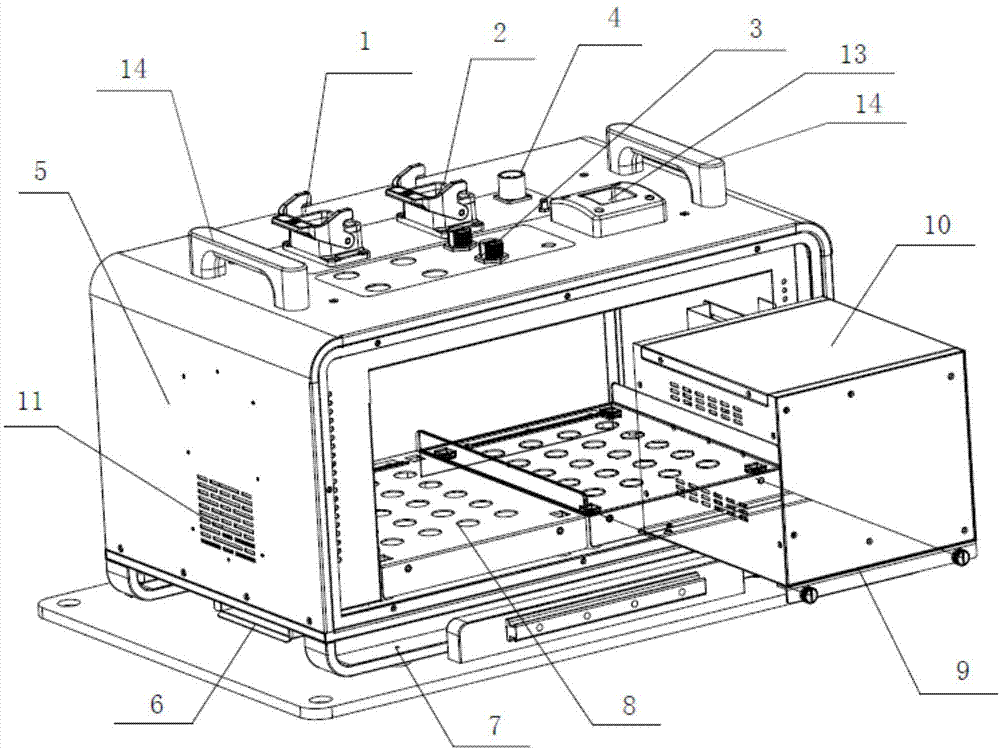

[0032] The invention relates to a mainframe of a track inspection system, and its structure principle diagram is as follows figure 1 As shown, it includes a host chassis 5 and a patrol server and a control device that are all set inside the host chassis 5. The host chassis is provided with a signal input interface and more than one misplug-proof signal output interface, figure 1 The illustrated embodiment is an output interface for preventing misplugging signals, and multiple output interfaces for preventing misplugging signals may also be provided. The control device includes a power supply device, a signal distribution module, and a programmable controller. The signal input interface is connected to the signal distribution module to prevent Wrong plug signal output interfaces are all connected to the inspection server, power supply device and signal distribution module, and the inspection ser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com