A battery module pressing device and its stand

A battery module and bench technology, applied in the field of battery module pressing equipment and its bench, to achieve the effects of convenient adjustment, convenient riveting, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

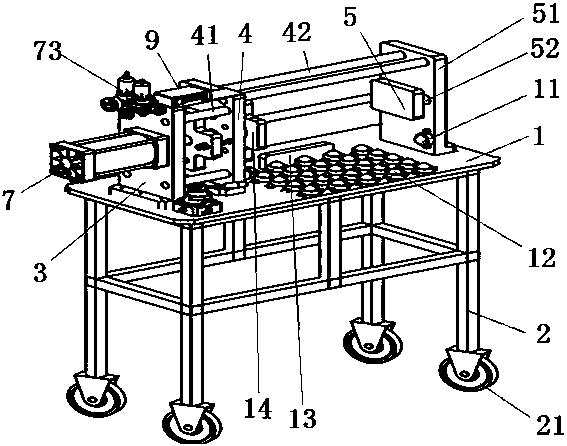

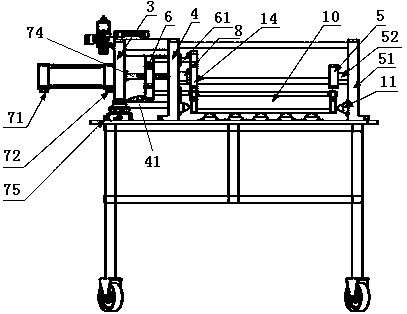

[0045] A specific embodiment of the battery module pressing device of the present invention, such as Figure 2 to Figure 9 As shown, the battery module pressing equipment includes a stand and a tray arranged on the extrusion station of the stand. The stand includes a bracket 2 and a platform 1 welded on the bracket 2. The bracket 2 is a height-adjustable frame with Four supporting legs, universal wheels 21 are installed on the bottom of the supporting legs to facilitate the movement of the equipment and improve portability. The platform 1 is a rectangular plate, and the platform 1 is fixed with the first baffle 3, the middle baffle 4 and the second baffle 5 by bolts from left to right along its length direction, wherein the first baffle 3 and the middle baffle 4 Directly fixed by bolts, the second baffle plate 5 is fixedly connected with the second moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com