Bearingless induction motor with square stator

An asynchronous motor, bearingless technology, used in asynchronous induction motors, electric components, electrical components, etc., can solve the problems of ineffective utilization, low power density, and increased motor temperature, and ensure normal output torque and power density. , the effect of improving power density and critical speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

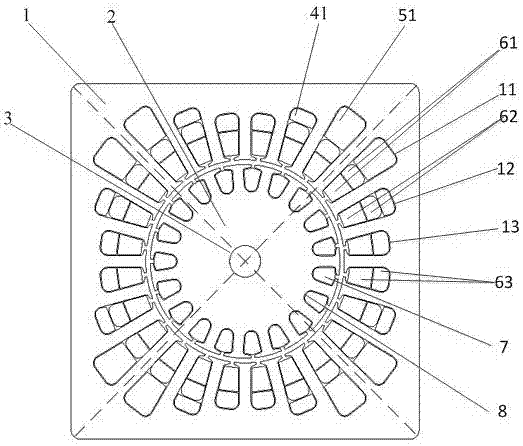

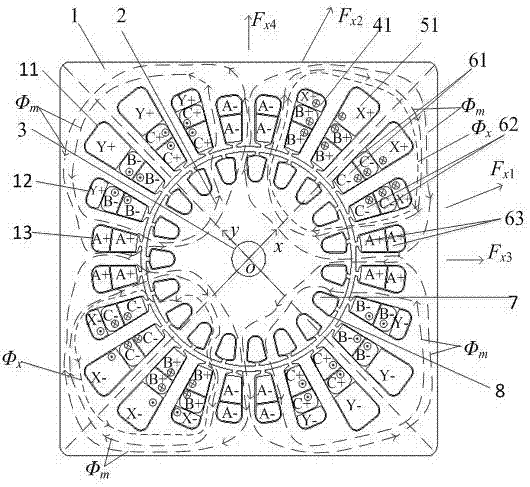

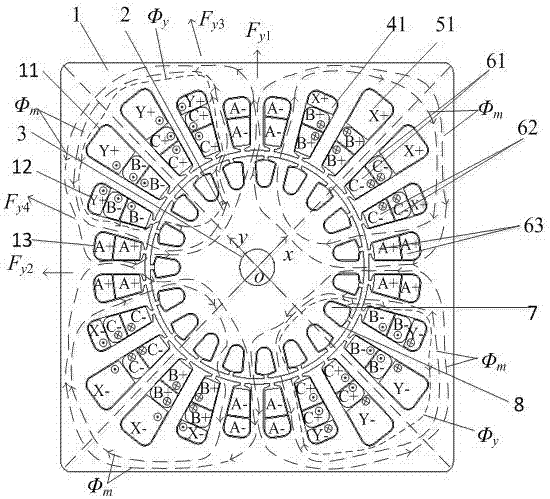

[0013] see figure 1 , the center of the present invention is the rotating shaft 3, the rotor core 2 is coaxially fixed outside the rotating shaft 3, the square stator 1 is coaxially sleeved outside the rotor core 2, and there is a radial gap between the rotor core 2 and the square stator 1 . The cross section of the outer wall of the square stator 1 is square, the inner hole is circular, and there is a radial gap between the inner hole wall and the outer wall of the rotor core 2 .

[0014] Each of the four corners of the square of the square stator 1 has arc chamfering. The square stator 1 is provided with 24 stator slots to form 24 stator teeth. The 24 stator slots are evenly arranged along the circumferential direction, and the angle between the centers of two adjacent stator slots is 15 degrees. The 24 stator slots are composed of 8 identical large slots 11, 8 identical middle slots 12, and 8 identical small slots 13. Each of the 8 identical large grooves 11 is in group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com