Drive axle for electric vehicle

A technology for electric vehicles and drive axles, which is applied to vehicle components, axles, wheels, etc., can solve the problems of increasing wear of drive axle components, reducing the service life of drive axles, and reducing driving efficiency, so as to achieve no increase in wear and improve safety , to avoid the effect of energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

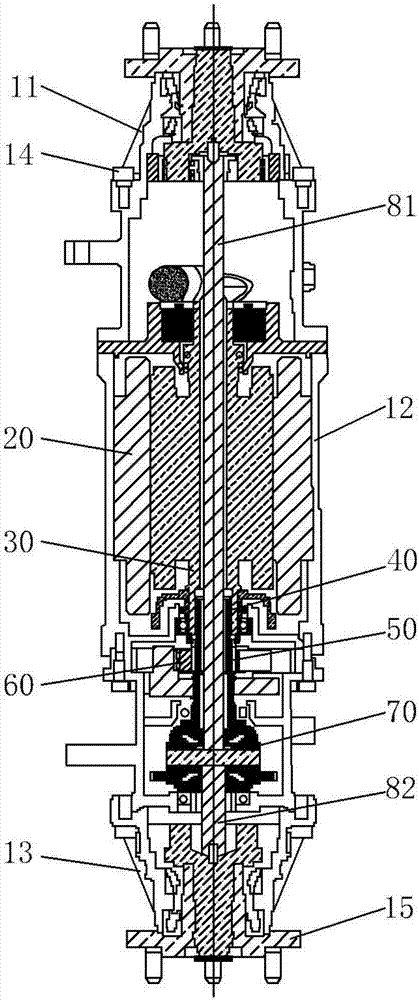

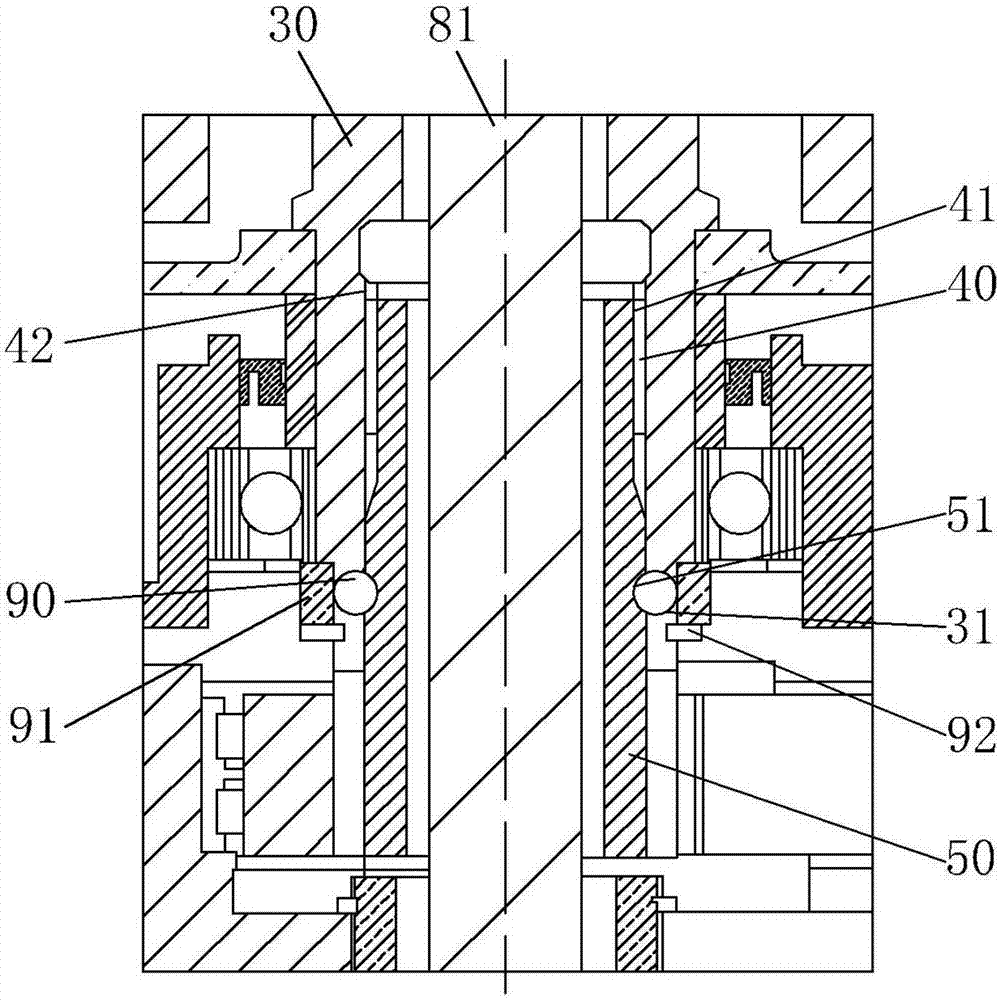

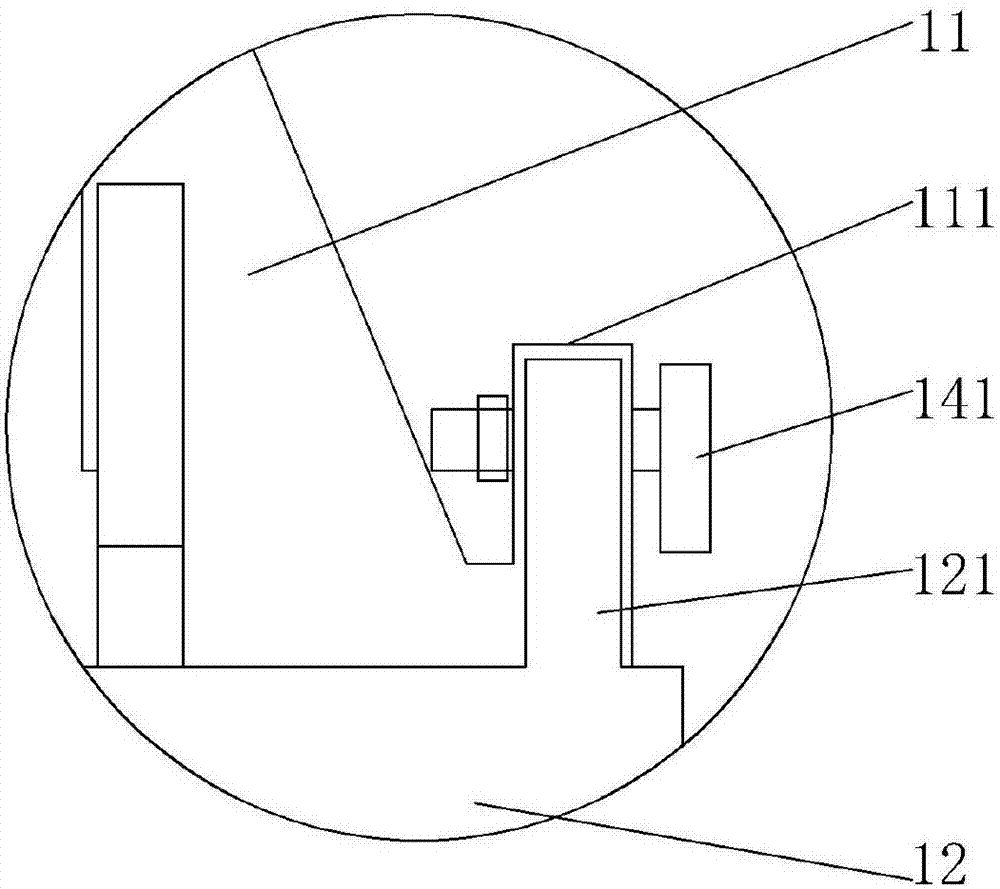

[0019] see Figure 1 ~ Figure 3 , a driving axle for an electric vehicle according to the present invention includes a driving axle housing and a driving motor 20, a hollow shaft 30, a connecting shaft 40, a sun gear 50, a planetary stage 60, a differential Driven gear 70, left half axle 81, right half axle 82 and at least two driving bodies 90. The drive motor 20 coaxially drives the hollow shaft 30 to form a drive shaft. The driving torque of the driving motor 20 is transmitted to the connecting shaft 40 via the hollow shaft 30 , and then transmitted to the sun gear 50 and the planetary stage 60 . The hollow shaft 30 is rotatably connected with the sun gear 50 , and can slide along the axial direction of the sun gear 50 , and the radial cleara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com