Modified plastic and manufacturing method thereof

A plastic and modified technology, applied in the field of materials, can solve the problems of low notch impact strength, easy to be corroded by halogenated hydrocarbons, large molding shrinkage rate, etc., to achieve the effect of low molding shrinkage rate, overcoming notch sensitivity, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

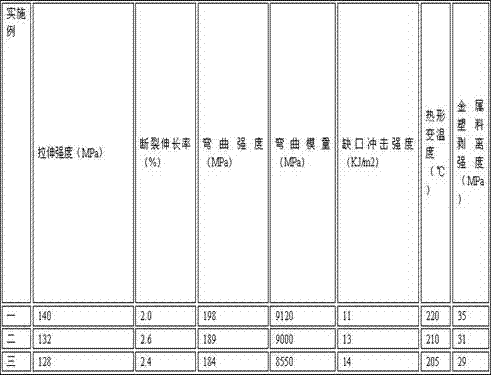

Examples

Embodiment 1

[0021] Embodiment 1: a kind of modified plastic, the mass percent of each component is:

[0022] Polybutylene terephthalate 60%;

[0023] Toughener 1%;

[0024] Lubricant 0.4%;

[0025] Compatibilizer 2.7%;

[0026] Reinforcing agent glass fiber 33%;

[0027] Nanomaterials 0.6%;

[0028] Antioxidant 0.8%;

[0029] Coupling agent 1.5%.

Embodiment 2

[0030] Embodiment two: a kind of modified plastics, the mass percent of each component is:

[0031] Polybutylene terephthalate (PBT) 65%;

[0032] Toughener 1%;

[0033] Lubricant 0.4%;

[0034] Compatibilizer 2%;

[0035] Reinforcing agent glass fiber 29%;

[0036] Nanomaterials 0.5%;

[0037] Antioxidant 0.8%;

[0038] Coupling agent 1.3%.

Embodiment 3

[0039] Embodiment three: a kind of modified plastic, the mass percent of each component is:

[0040] Polybutylene terephthalate (PBT) 58%;

[0041] Toughener 1%;

[0042] Lubricant 0.4%;

[0043] Compatibilizer 3%;

[0044] Reinforcing agent glass fiber 35%;

[0045] Nanomaterials 0.6%;

[0046] Antioxidant 0.8%;

[0047] Coupling agent 1.2%.

[0048] A method for manufacturing modified plastics, the steps are as follows:

[0049] S1 Dry the polybutylene terephthalate at 120°C-140°C, and dry the nanomaterial at 100°C-110°C for use;

[0050] S2 Weigh the dry polybutylene terephthalate and nanomaterials according to a certain mass percentage ratio, add them to the high-speed mixer, and add glass fiber, toughening agent and lubricant according to the mass percentage ratio at the same time , compatibilizer, coupling agent, and antioxidant, stirred for 10 minutes, and discharged after being fully mixed;

[0051] S3 Place the mixed material in a twin-screw extruder and comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com