GH2132 high-temperature alloy and heat treatment method for improving hardness of GH2132 high-temperature alloy

A technology of GH2132 and heat treatment method, applied in the field of heat treatment of GH2132 superalloy and improving the hardness of GH2132 superalloy, can solve the problems of low plasticity and insufficient hardness, achieve excellent tensile strength, good plasticity and cutting performance, and overcome notch sensitivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

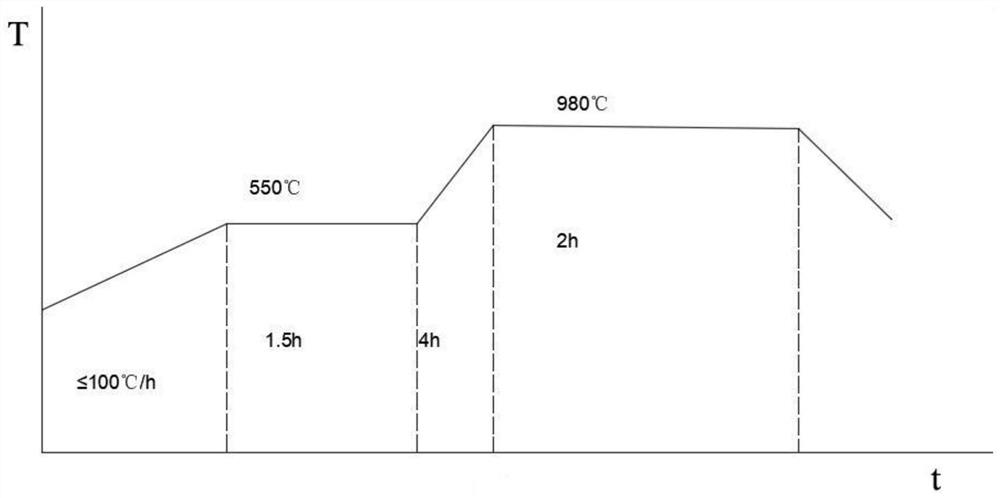

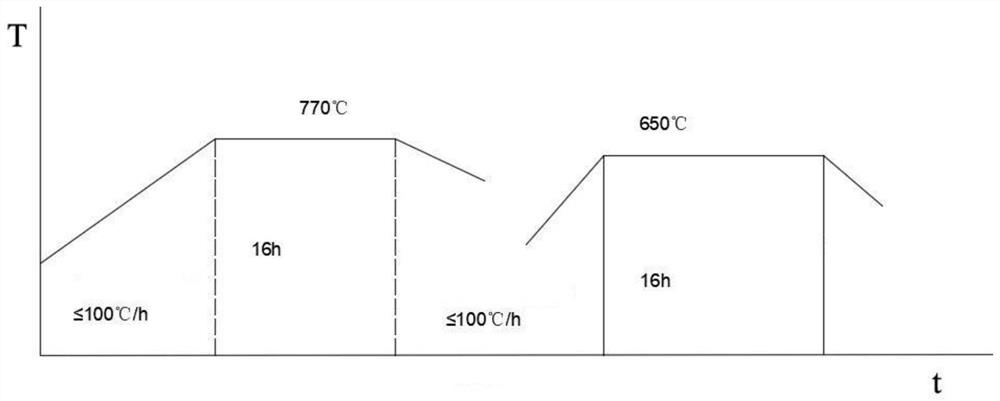

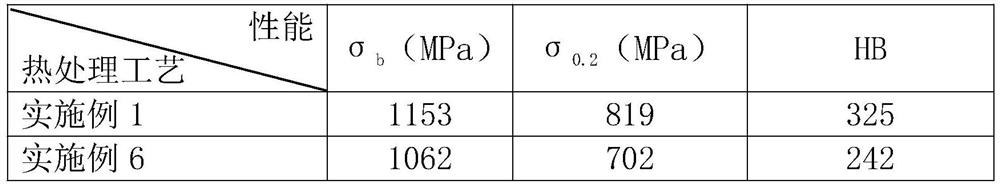

Embodiment 1

[0028] A GH2132 superalloy round bar blank with a size of 120*1500mm, made from the following raw materials by mass fraction: Ni: 24.0%, C: 0.01%, Cr: 13.5%, Ti: 1.75%, Al: 0.1% , Mn: 1.5%, Si: 0.8%, B: 0.00%, and the balance is Fe; the heat treatment method to improve its hardness includes the following steps:

[0029] S1. One-time charging: put five GH2132 superalloy round bar blanks into the solution treatment furnace. When loading the furnace, the interval between the round bar blanks is 50mm, and the middle of the round bar blanks is separated by refractory bricks. The present invention The amount of furnace charging before solution treatment should not be too large, because GH2132 has many high-temperature alloy elements, poor thermal conductivity, and slow microstructure transformation. During the heating process, the transformation of the bar in the center of the tray is incomplete, and there may be a considerable amount of it. The γ' is not dissolved in the matrix, re...

Embodiment 2

[0037] A GH2132 superalloy round bar blank with a size of 50*1000mm, made of the following raw materials by mass fraction: Ni: 24.5%, C: 0.02%, Cr: 14.5%, Ti: 1.85%, Al: 0.1% , Mn: 1.32%, Si: 0.2%, B: 0.005%, and the balance is Fe; the heat treatment method for improving its hardness includes the following steps:

[0038] S1. One-time furnace loading: 20 GH2132 superalloy round bar blanks of the above size are loaded into the solution treatment furnace. When loading the furnace, the interval between the round bar blanks is 50mm, and the middle of the round bar blanks is separated by refractory bricks , In the present invention, the amount of furnace charging before solution treatment should not be too large, because GH2132 has many high-temperature alloy elements, poor thermal conductivity, and slow microstructure transformation. A considerable amount of γ' is not dissolved in the matrix, resulting in the precipitation and distribution of the γ' phase not meeting the requireme...

Embodiment 3

[0046] A GH2132 superalloy round bar blank with a size of 120*1500mm, made from the following raw materials by mass fraction: Ni: 25.0%, C: 0.01%, Cr: 15%, Ti: 1.95%, Al: 0.1% , Mn: 1.2%, Si: 0.1%, B: 0.006%, and the balance is Fe; the heat treatment method for improving the hardness is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com