Anti-static polybutylene terephthalate (PBT) material with excellent comprehensive performance and preparation method thereof

A comprehensive performance, antistatic technology, applied in the field of engineering plastics PBT, can solve the problems of compound molding processing performance and mechanical properties, inconvenience in production and life, poor antistatic performance, etc., to meet the requirements of antistatic function and product quality Stable and ensure the effect of surface cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

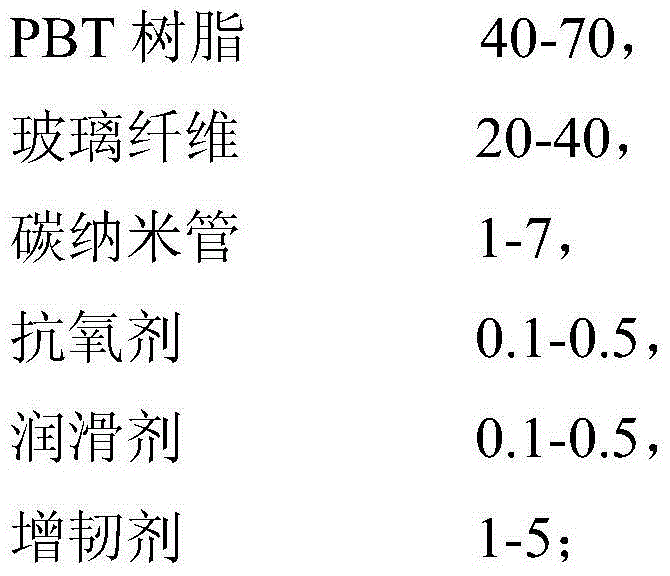

Method used

Image

Examples

Embodiment 1

[0030] Mix 440g of PBT resin, 50g of antistatic PBT masterbatch, 5g of antioxidant composed of hindered phenols and phosphites in a mass ratio of 1:1.5, 5g of lubricant and 30g of epoxy resin toughener, and mix evenly. The amount of fiber added is controlled at 37 wt%, and melt blending, extrusion, traction, and granulation are carried out in a twin-screw extruder. After pelletizing, use an injection molding machine to inject the obtained pellets at a temperature of 245°C to obtain ASTM standard test specimens for product performance testing. See Table 1 for test data.

Embodiment 2

[0032] Mix 390g of PBT resin, 100g of antistatic PBT masterbatch, 5g of antioxidant composed of hindered phenols and phosphites in a mass ratio of 1:1.5, 5g of lubricant and 30g of epoxy resin toughener, and mix evenly. The amount of fiber added is controlled at 37 wt%, and melt blending, extrusion, traction, and granulation are carried out in a twin-screw extruder. After pelletizing, use an injection molding machine to inject the obtained pellets at a temperature of 245°C to obtain ASTM standard test specimens for product performance testing. See Table 1 for test data.

Embodiment 3

[0034] Mix 340g of PBT resin, 150g of antistatic PBT masterbatch, 5g of antioxidant composed of hindered phenols and phosphites in a mass ratio of 1:1.5, 5g of lubricant and 30g of epoxy resin toughener, and mix evenly. The amount of fiber added is controlled at 37 wt%, and melt blending, extrusion, traction, and granulation are carried out in a twin-screw extruder. After pelletizing, use an injection molding machine to inject the obtained pellets at a temperature of 245°C to obtain ASTM standard test specimens for product performance testing. See Table 1 for test data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com