Composite lubricating oil suitable for low temperature environment, and preparation method thereof

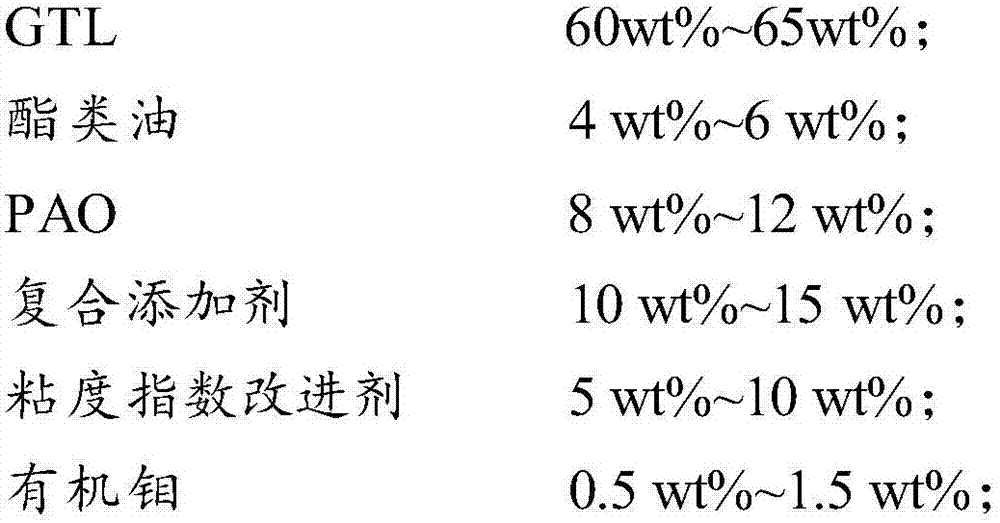

A low temperature environment, lubricating oil technology, applied in the field of lubricating oil, can solve the problems of inability to decompose, unfavorable anti-friction performance, etc., to achieve the effect of improving solubility, improving low temperature flow effect, and alleviating low temperature cold start

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Compounding of compound GTL synthetic oil

[0041] Mix GTL100 and GTL250 at a ratio of 11:10, heat to 60°C and stir for 30 minutes.

[0042] 2) Preparation of ester oil

[0043] Mix diisodecyl adipate and polyisobutylene fumarate at a ratio of 3:2, heat to 70°C and stir for 30 minutes.

[0044] 3) Preparation of organic molybdenum concentrate

[0045] Add molybdenum dialkyldithiocarbamate to the ester oil prepared in 2) at a mass ratio of 1:5, heat to 60°C and stir for 15 minutes.

[0046] 4) Preparation of compound lubricating oil

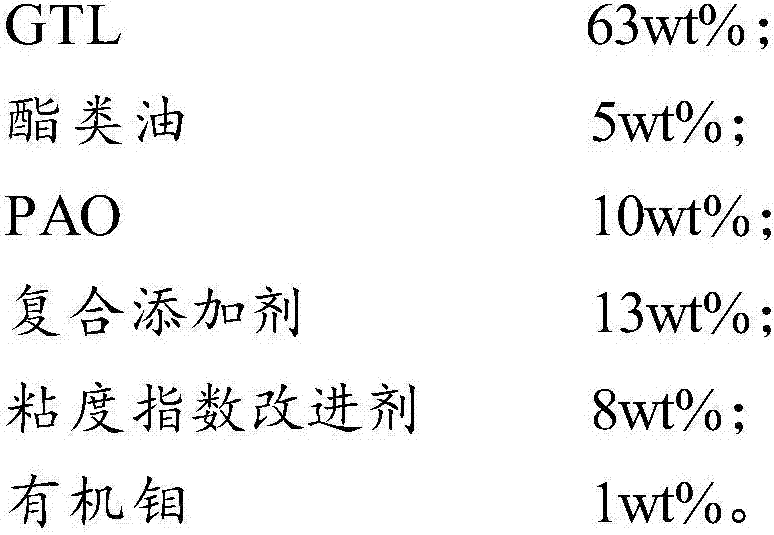

[0047] The ester oil, PAO 6, composite additives that are dissolved with organic molybdenum, PAO 6, composite additives that are made in 3): Afton (Afton) additive company's 8744B, polyhydrogenated styrene isoprene type viscosity index improver: SV261 is added to the composite GTL prepared in 1), the ratio is GTL: PAO: ester oil containing organic molybdenum: composite additive: viscosity index improver = 63 :10:6:13:8 (mass ratio)...

Embodiment 2

[0057] 1) Compounding of compound GTL synthetic oil

[0058] Mix GTL100 and GTL250 at a ratio of 11:10, heat to 60°C and stir for 30 minutes.

[0059] 2) Preparation of ester oil

[0060] Mix diisodecyl adipate and polyisobutylene fumarate at a ratio of 3:2, heat to 70°C and stir for 30 minutes.

[0061] 3) Preparation of organic molybdenum concentrate

[0062] Add molybdenum dialkyldithiophosphate to the ester oil prepared in 2) at a mass ratio of 1:5, heat to 60°C and stir for 15 minutes.

[0063] 4) Preparation of compound lubricating oil

[0064]The organic molybdenum-dissolved ester oil, PAO 6, compound additives obtained in 3): OLOA59094 from Chevron Oronite Company, polyhydrogenated styrene isoprene type viscosity index improver: SV261 are added to 1 Composite GTL prepared in ). The ratio is GTL:PAO:molybdenum-containing ester oil:compound additive:viscosity index improver=63:10:6:13:8.

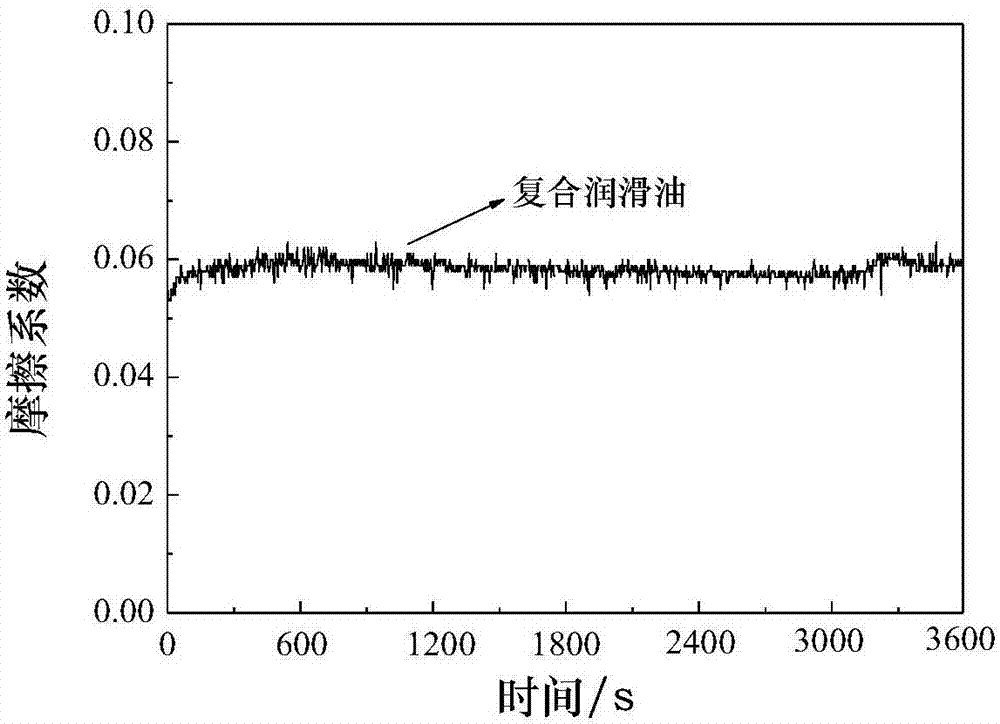

[0065] The performance of the lubricating oil was detected by the same metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com