Waterway connecting structure and large flow rate waterway assembly

A connection structure and large flow technology, applied in the field of sanitary ware, to achieve the effect of simple connection structure, convenient assembly, and saving transition space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

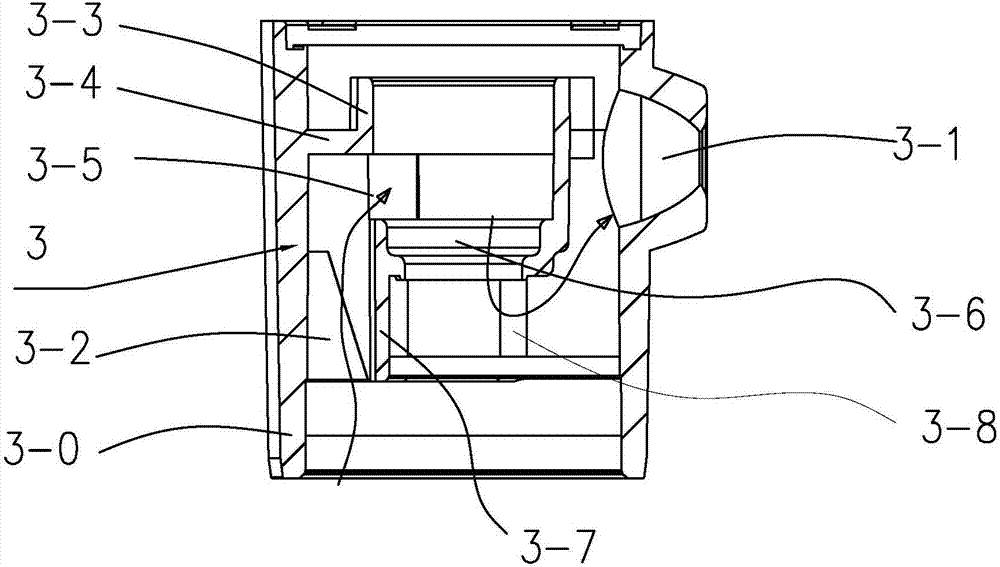

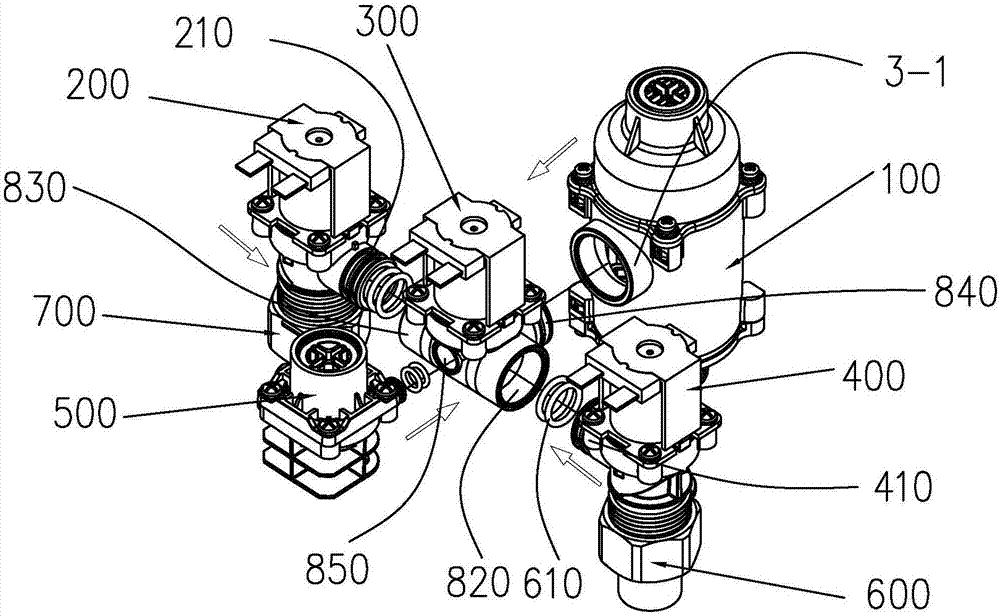

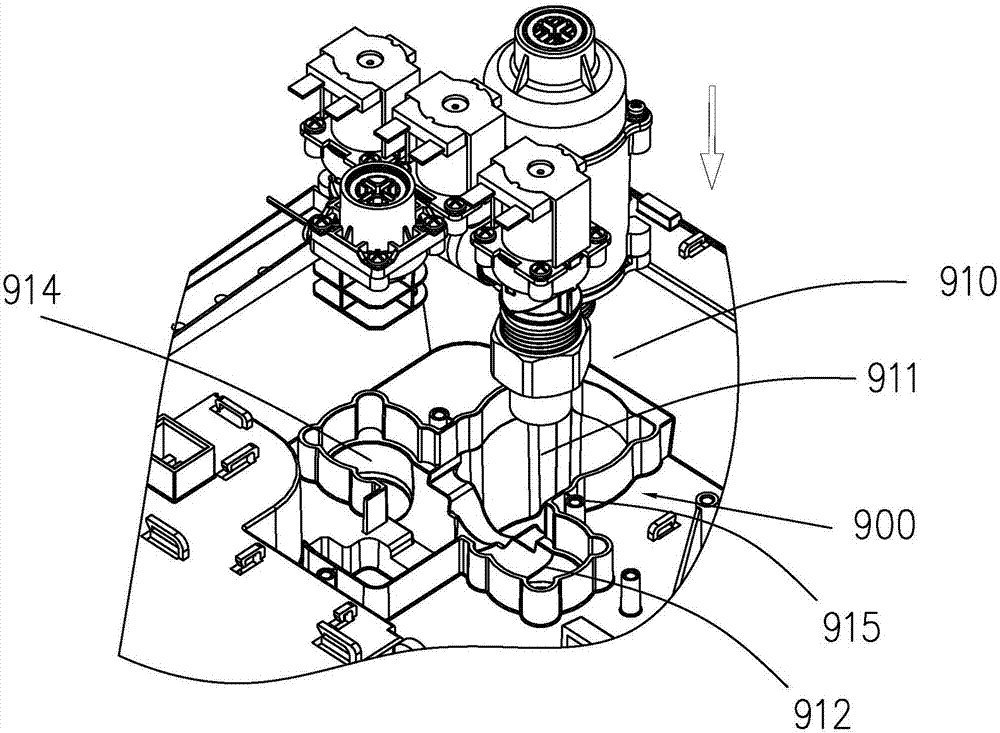

[0051] For specific embodiments of the present invention, refer to Figure 5 to Figure 8 , The water fitting is mainly composed of a large flow voltage stabilization unit 100, a brush coil solenoid valve unit 200, a washing solenoid valve unit 300, a spray solenoid valve unit 400, and a washing voltage stabilization unit 500.

[0052] Wherein, the water inlet 1 of the large-flow voltage stabilization unit 100 is connected to a water source (such as a water pipe), and after the water flow enters the large-flow voltage stabilization unit 100, the first voltage stabilization is performed, and the water outlet 3-1 on the side thereof is connected to a multi-channel pipe. The water inlet end 840 of the road 800, the outlet end of the multi-channel pipeline 800 is divided into three water outlets 810 in the middle, 820 in the left and 830 in the right (see image 3), wherein the middle water outlet 810 is connected to the washing solenoid valve unit 300, and the solenoid valve unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com