Manual butt-joint locking steel bar connector

A steel connector and connector technology, applied in the direction of structural elements, building components, building insulation materials, etc., can solve the problems of insufficient operation convenience, insufficient reliability, and stuck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

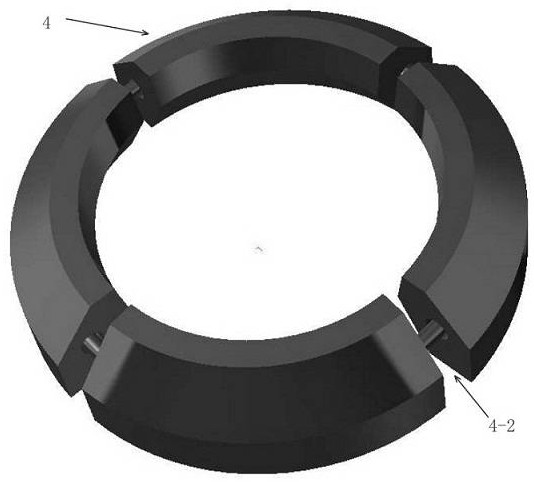

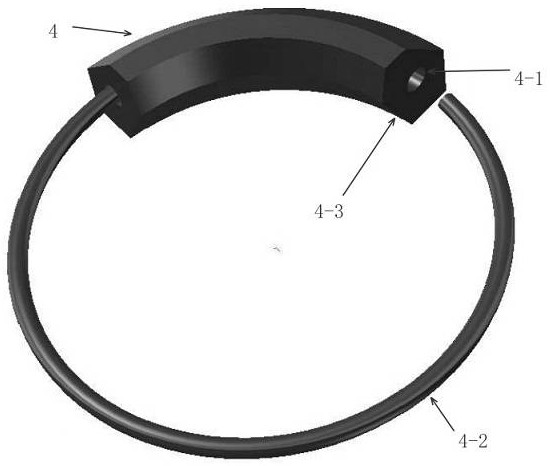

[0029] The main implementation mode of this patent is: the connecting punch (2) and the connecting locking sleeve (3) are respectively installed at the ends of the two steel bars (1) that need to be connected; (5) Install it into the connection lock sleeve (3); then use the elasticity of the spring coil (4-2) in the spring control block (4) to install the spring control block (4) into the connection lock sleeve ( 3), and the stable spring (5) provides continuous upward support to ensure the stability and position of the spring control block (4); the conical surface (2-4) at the front end of the connecting punch (2) provides a soothing Stretch the horizontal thrust of the spring control block (4); at this time, the steel wire that stabilizes the top of the spring (5-1) horizontally expands or retracts inwards can provide a stable support surface for the spring control block (4) to move horizontally. After the punch (2) reaches the limit (7), stabilize the compression reaction f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com