Short-flexspline type harmonic precision transmission device

A precision transmission and harmonic technology, applied in the direction of transmission, gear transmission, belt/chain/gear, etc., can solve the problems of low load capacity, low transmission efficiency, short life, etc., to achieve strong load capacity, compact structure, Effect of Axial Dimension Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment, further illustrate the present invention.

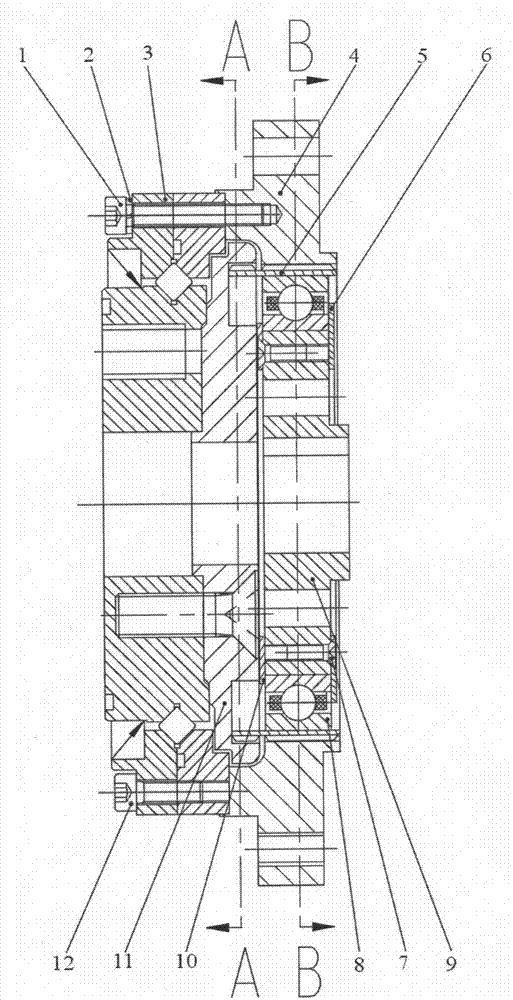

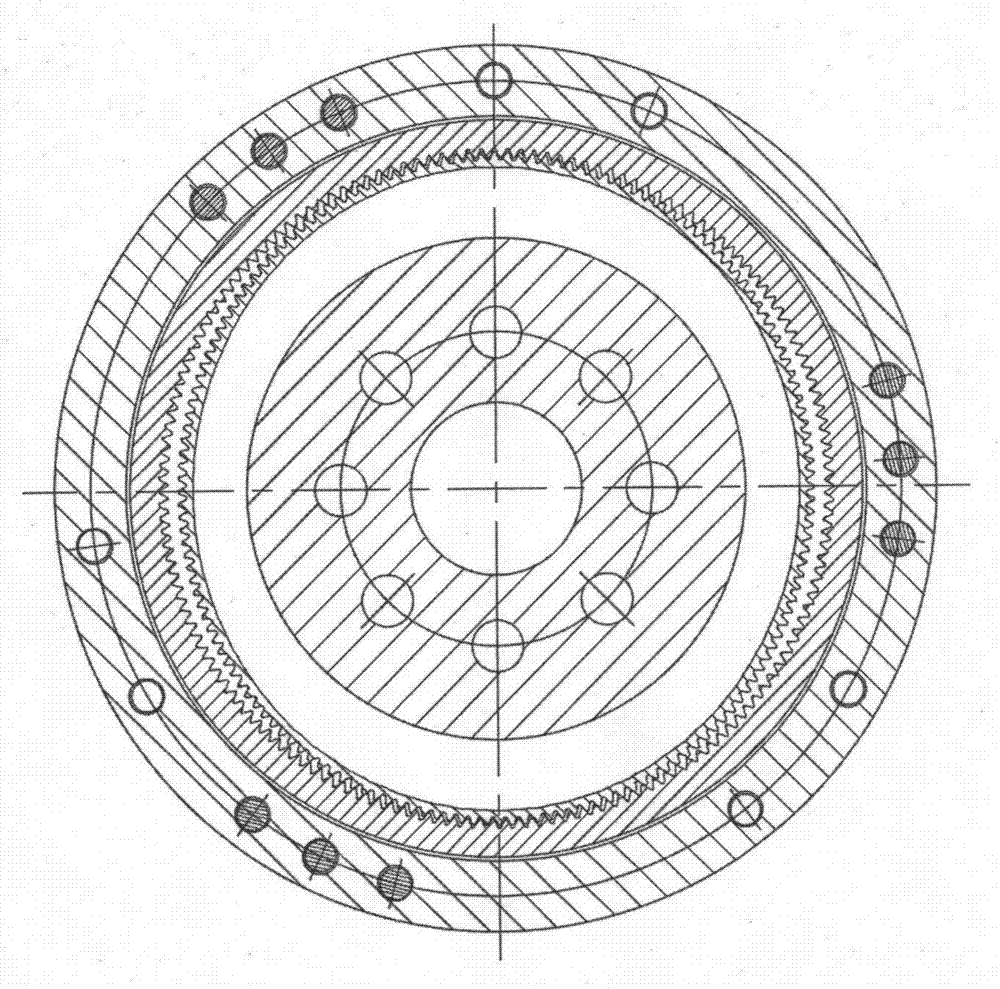

[0027] figure 1 The schematic diagram of the short-tube harmonic precision transmission device provided for this embodiment, the short-tube harmonic precision transmission device is composed of a connecting screw 1, a gasket 2, a cross bearing 3, a rigid wheel 4, a double flexible wheel 5, an inner Block plate 6, block plate screw 7, flexible bearing 8, shock wave device 9, outer block plate 10, output disk 11, bearing screw 12 etc. are formed.

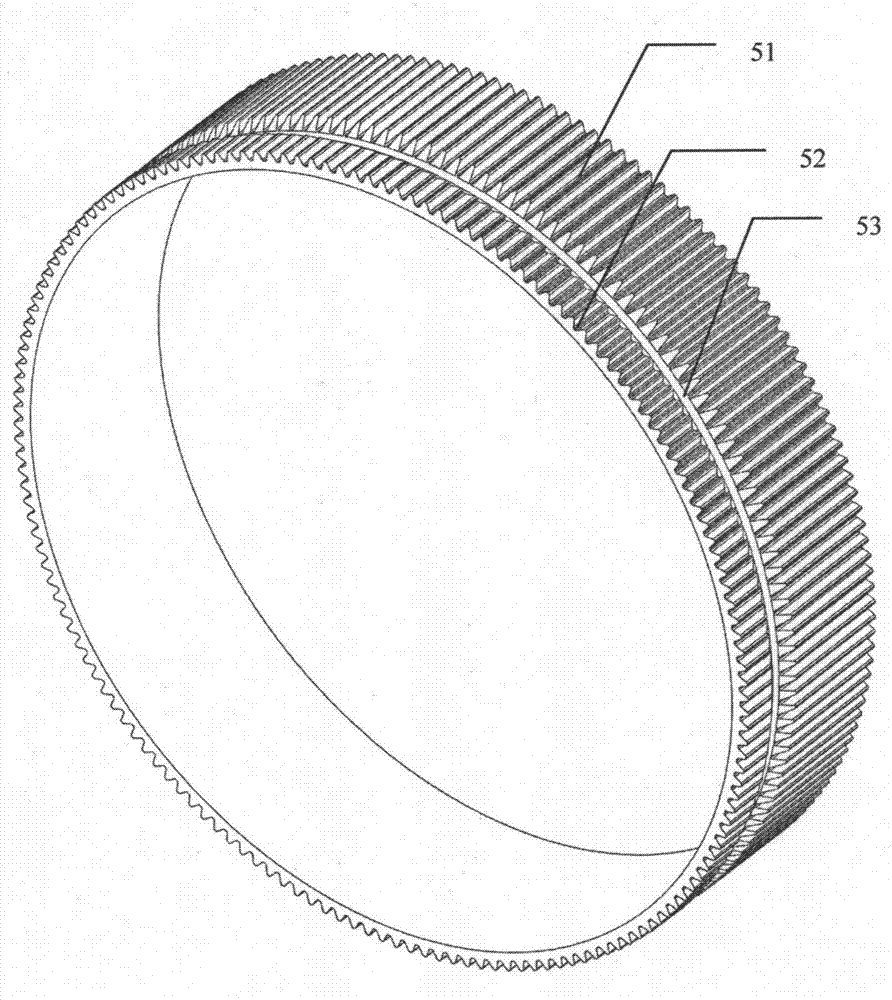

[0028] The inner ring of the flexible bearing 8 is installed on the shock wave device 9, and the flexible bearing 8 is fixed on the shock wave device 9 through the inner blocking plate 6 and the outer blocking plate 10, and the double flexible spline 5 is installed on the outer ring of the flexible bearing 8 Above, the outer ring of the flexible bearing 8 corresponds to the tooth segment of the deceleration part of the duplex flexspline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com