Method for on line monitoring fatigue damage of nuclear grade equipment and pipelines

A fatigue damage and equipment technology, which is applied in the field of nuclear power equipment safety research, can solve the problems of conservative cumulative fatigue utilization coefficient, complex fatigue design of nuclear-level equipment and pipelines, and reduce the conservativeness of fatigue calculation, so as to simplify the technical effect and reduce the conservativeness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

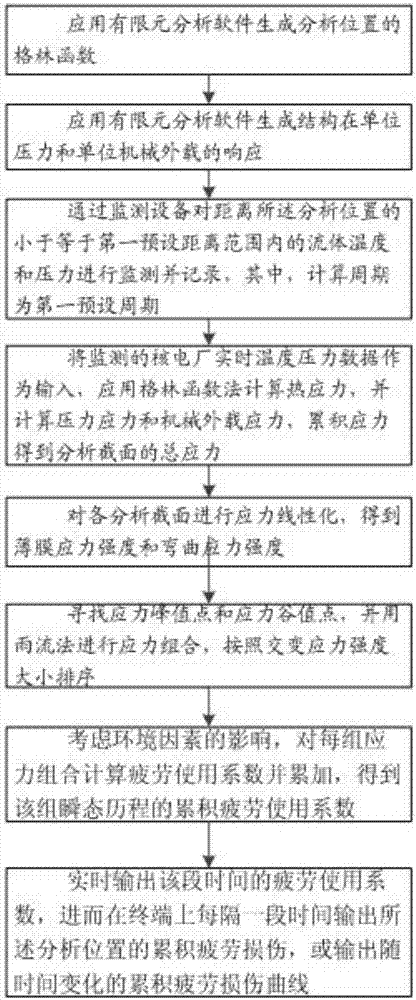

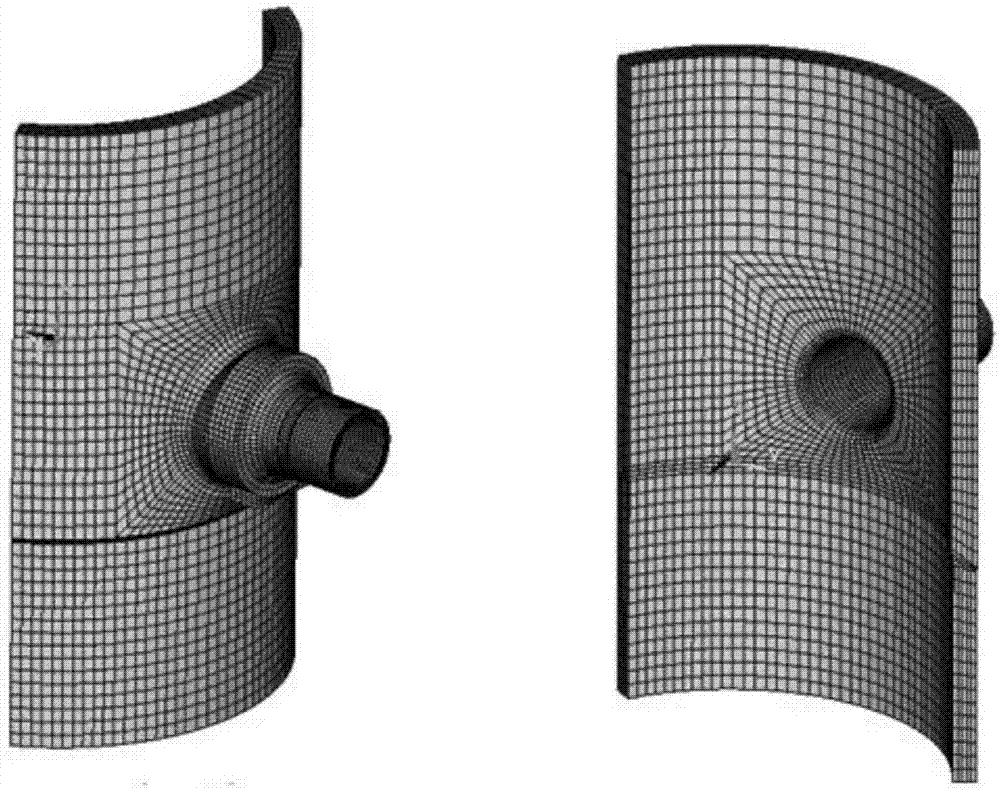

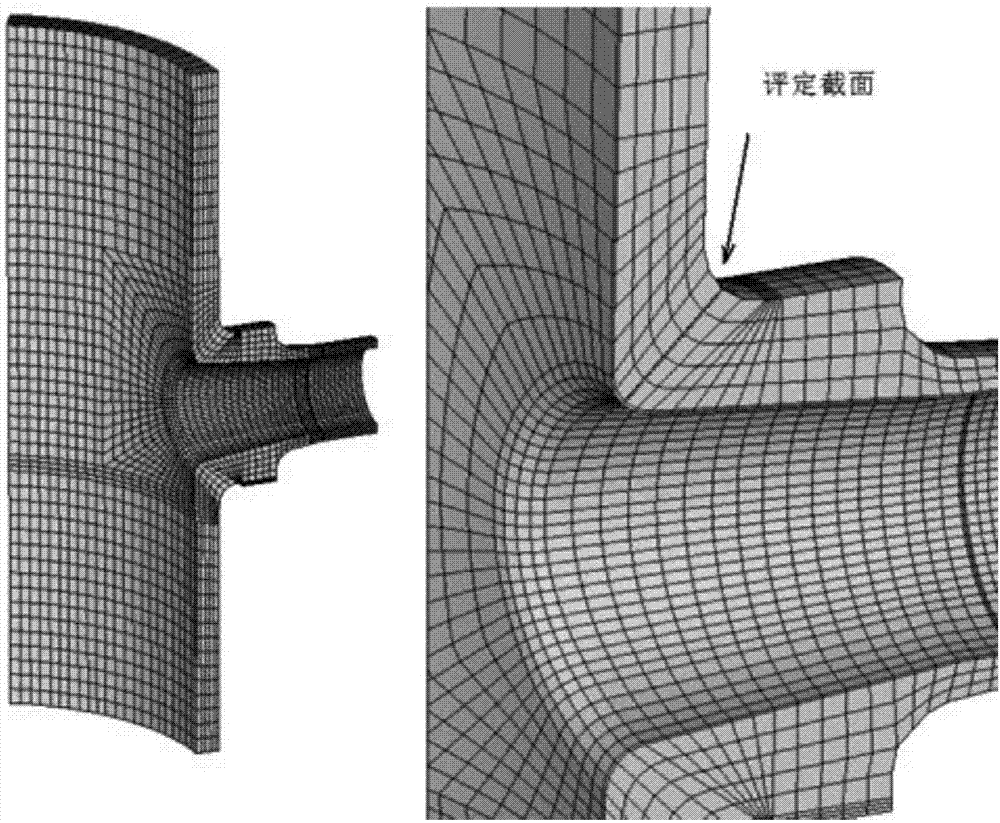

[0057] In Embodiment 1, a method for online monitoring of nuclear-level equipment and pipeline fatigue damage is provided, please refer to Figure 1-Figure 7 , the method includes:

[0058] First, apply the finite element analysis software to generate the Green's function of the analysis position;

[0059] Then, apply finite element analysis software to generate the response of the structure at unit pressure and unit mechanical external load;

[0060] Then, monitor and record the temperature and pressure of the fluid within a range of less than or equal to a first preset distance from the analysis position by the monitoring device, wherein the calculation period is the first preset period;

[0061] Then, the real-time temperature and pressure data of the monitored nuclear power plant are used as input, and the Green's function method is used to calculate the thermal stress, and calculate the pressure stress and mechanical external load stress, and accumulate the stress to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com