Water-driven flue gas purification device for ship

A flue gas purification and purification device technology, applied in the field of flue gas purification, can solve problems such as smoke elimination and purification that are not suitable for ship fires, and achieve the effects of simple structure, convenient engineering overhaul and maintenance, and convenient access.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

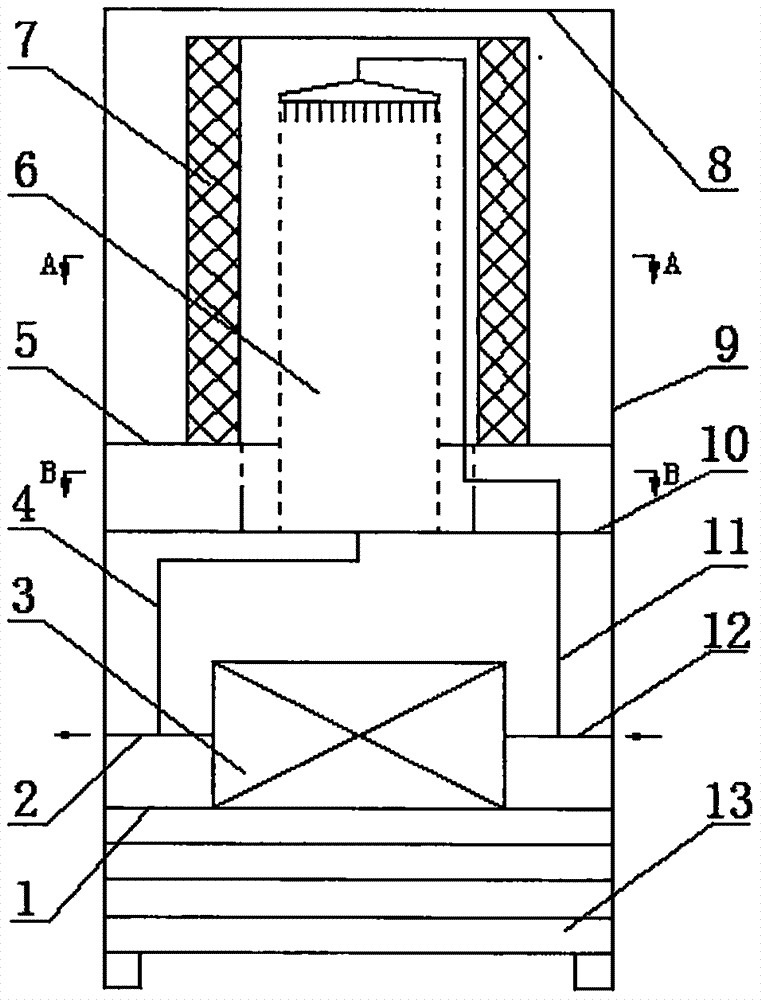

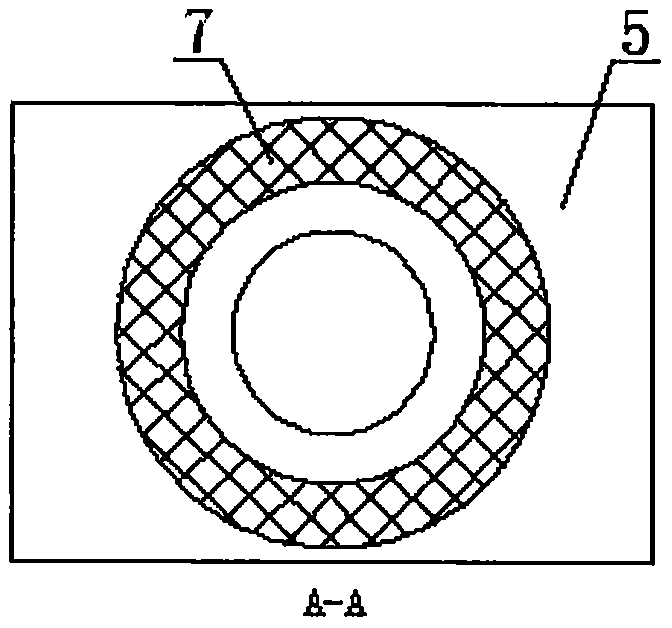

[0033] Disclosed is a device for purifying flue gas from ships driven by water. Such as figure 1 As shown, the purification device consists of a fan base plate 1, an outlet pipe 2, a water drive fan 3, a spray return pipe 4, a mounting plate 5, a spray unit 6, a filter cartridge 7, a wire mesh 8, a housing 9, and a bracket 10. It is composed of spray water supply pipe 11, water inlet pipe 12 and shutters 13.

[0034] Such as figure 1 As shown, one end of the water inlet pipe 12 is connected to the water inlet of the water-driven fan 3, and the other end passes through the housing 9 to externally connect to a high-pressure water source. One end of the water outlet pipe 2 is connected to the water outlet of the water-driven fan 3 , and the other end passes through the housing 9 . One end of the spray water supply pipe 11 is connected with the water inlet pipe 12 , and the other end is connected with the spray unit 6 . One end of the spray return pipe 4 is connected with the ...

Embodiment 2

[0042] Disclosed is a device for purifying flue gas from ships driven by water. Such as Figure 5 As shown, the purification device consists of a fan base plate 1, an outlet pipe 2, a water drive fan 3, a spray return pipe 4, a mounting plate 5, a spray unit 6, a filter cartridge 7, a wire mesh 8, a housing 9, and a bracket 10. It is composed of spray water supply pipe 11, water inlet pipe 12 and shutters 13. Except following technical parameter, all the other are with embodiment 1:

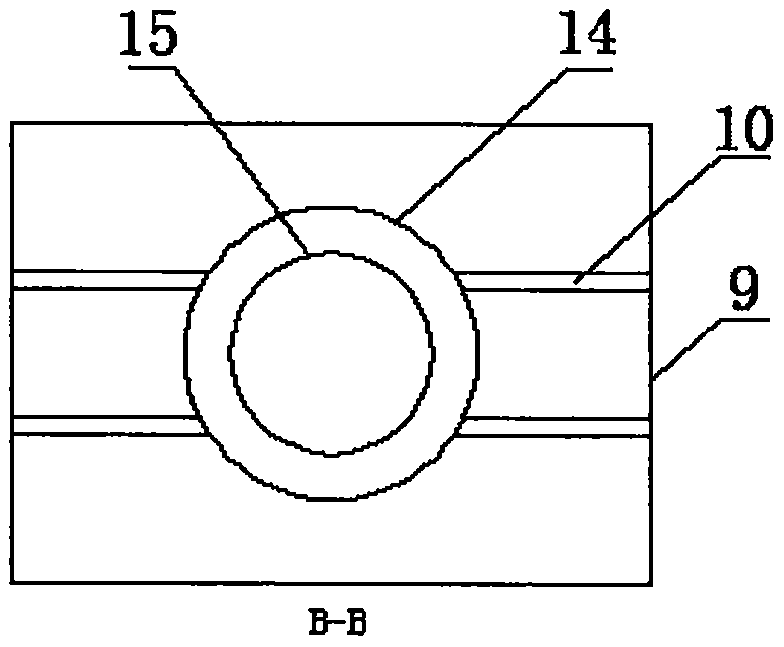

[0043] Such as Figure 5 , Figure 6 and Figure 7 As shown, the installation plate 5 is a flower plate, and the spray unit 6 and the filter cartridge 7 are multiple parallel structures. Each spray unit 6 is connected with a spray water supply pipe 11 and a spray return pipe 4 . Each spray water supply pipe 11 is connected with the water inlet pipe 12 , and each spray return water pipe 4 is connected with the water outlet pipe 2 . Each row of spray units 6 is fixed on the housing 9 through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com