Function and capacity modular design-based non-point source water purification bioreactor and preparation method thereof

A modular design, bioreactor technology, applied in the treatment of non-point source pollution sources, to improve removal efficiency, reduce time consumption, and facilitate repair and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

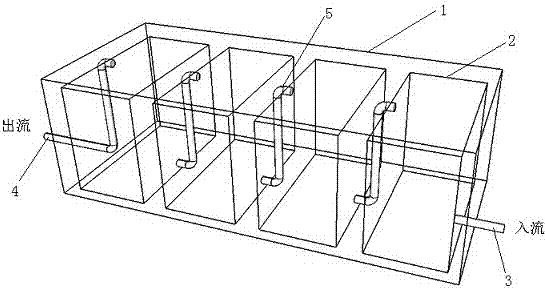

[0028] like figure 2 As shown, a non-point source water purification bioreactor based on the modular design of function and capacity, the reactor 1 is a cuboid structure (open structure), and the reactor is provided with several unit packing module boxes along the length direction (Open structure) 2. Different fillers are placed in each unit packing module box, such as activated carbon, sawdust, slag, cinder, etc.

[0029] The lower right side of the reactor is provided with an inflow pipe 3, the inflow pipe extends into the reactor and is connected to the lower right side of the rightmost unit packing module box, and the inflow pipe communicates with the unit packing module box; the left lower part of the reactor There is an outlet pipe 4, which extends into the reactor and is connected to the left lower part of the leftmost unit packing module box, and the outlet pipe communicates with the unit packing module box; two adjacent units in the reactor The packing module boxes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com