Adsorption and desorption/exploitation simulated experimental device and method of shale gas

A simulation experiment device, adsorption and desorption technology, which is applied in material inspection products, instruments, analytical materials, etc., can solve the problems of reduced control accuracy, low measurement accuracy, and the reliability of simulation test results without mining. The effect of saving equipment investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A shale mining simulation experiment method, the method comprising:

[0067] A. After the adsorption experiment is over, carry out the constant pressure mining simulation experiment:

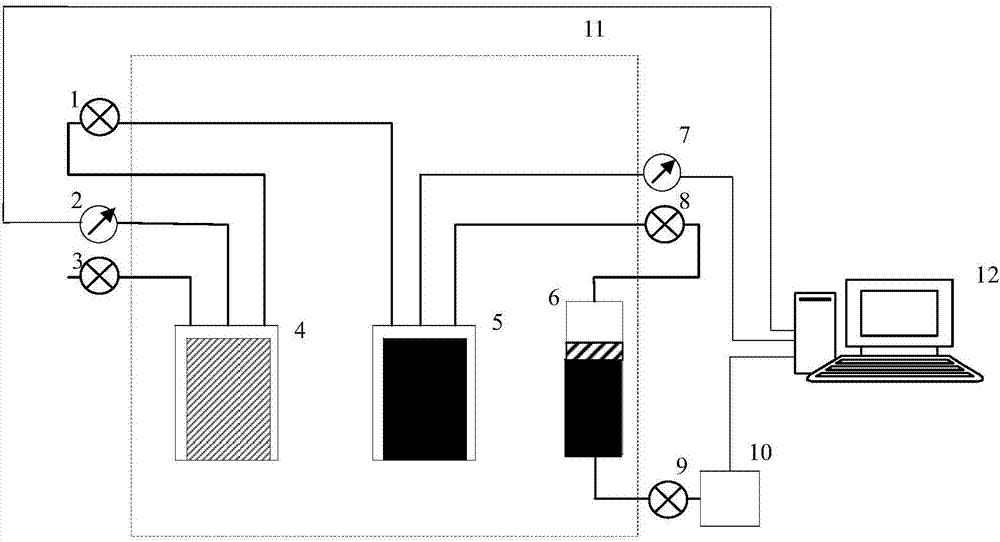

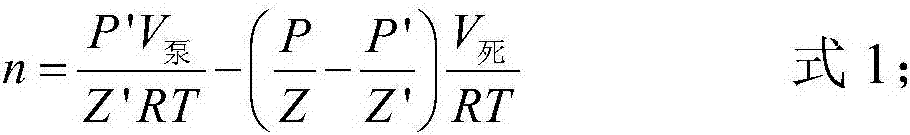

[0068] 1) The volume V of the sample is measured before the experiment 样 , mass m measurement, the sum of the volume V of the volume of the sample cylinder 5 and the volume of the pipeline between the cylinder body and the valve 8 下 Carry out calibration, the temperature T of setting thermostat 11 is experimental temperature;

[0069] 2) Close valve 1 and open valve 8;

[0070] 3) After the system pressure formed by the sample cylinder 5, the piston intermediate container 6 and the pipeline is stable, the initial pressure P is recorded by the pressure sensor 7, and the valve 8 is closed;

[0071] 4) Set the high-precision plunger pump 10 to the constant pressure mode, and set the pump pressure to the first experimental pressure value. At this time, start to withdraw the pump. After the...

Embodiment 2

[0086] A shale mining simulation experiment method, the method comprising:

[0087] A. After the adsorption experiment is over, carry out the production-fixed mining simulation experiment:

[0088] 1) Ensure that the piston of the piston-type intermediate container 6 is at the top before the experiment; 样 , mass m metering, the sum of the volume V of the volume of the sample cylinder 5 and its connected pipeline and the volume of the piston upper end space in the piston intermediate container 6 下 Carry out calibration, the temperature T of setting thermostat 11 is experimental temperature;

[0089] 2) Close valve 1 and open valve 8;

[0090] 3) After the system pressure formed by the sample cylinder 5, the piston-type intermediate container 6 and the pipeline is stable, the initial pressure P is recorded by the pressure sensor 7, and the cumulative gas production volume of the high-precision plunger pump 10 is cleared;

[0091] 4) Set the high-precision plunger pump 10 to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com