Bean sprout growing machine

A bean sprout machine and electric motor technology, which is applied in the fields of agricultural gas emission reduction, botany equipment and method, soilless cultivation, etc., can solve the problems of artificial water replenishment, affecting the taste, time-consuming and labor-intensive, etc., so as to improve the growth rate and work efficiency efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

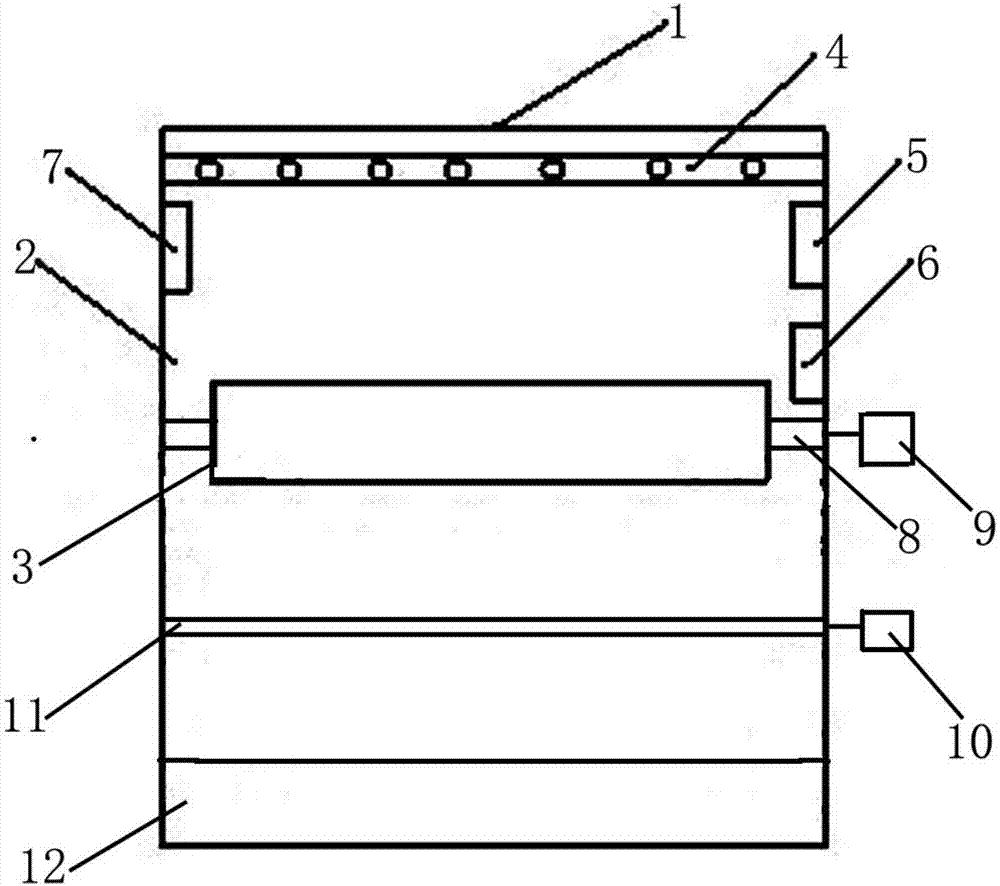

[0014] Such as figure 1 As shown, a bean sprouts machine includes a sprouting cabinet 1, in which a sprouting chamber 2 is provided, and a sprouting box 3 for holding bean sprouts is provided in the sprouting chamber 2, and the top of the germination chamber 2 is provided The spray device 4, the spray device 4 is a pipe arranged in multiple rows and having several water outlet holes. The spray device 4 is connected to a water tank, and a temperature sensor is provided in the water tank. The inner wall of the germination chamber 2 is provided with a temperature sensor 5, a humidity sensor 6 and a sterilization device 7, and the sterilization device 7 is an ultraviolet lamp.

[0015] The germinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com