porous metal rod

A porous metal and round rod technology, applied in the field of medical implanted porous metal rods, can solve the problems of affecting the fixation effect, prolong the operation time, and spend the tapping time, and achieve a good fixation effect, reduce the operation time, and reduce the stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

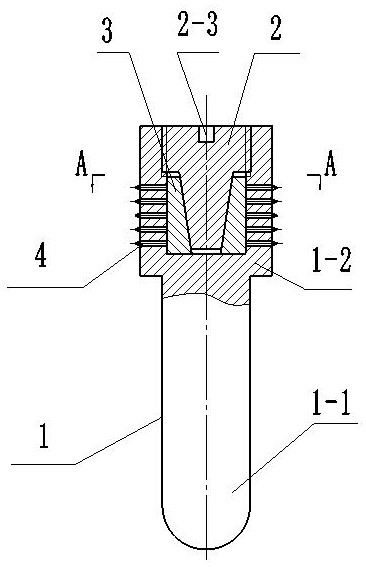

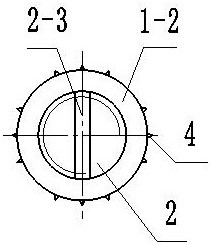

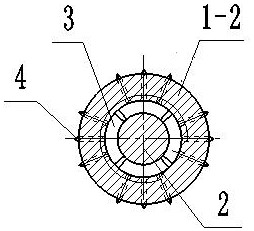

[0033] The porous metal rod structure of the present embodiment is as figure 1 As shown, the porous metal rod body 1 is made of metal tantalum, and the porous metal tantalum material is prepared by foam impregnation. The needle 4 is made of dense metal tantalum, the minimum wall thickness of the blind hole is 3 mm, the rounded corner r1 at the bottom of the straight wall hole 1-3-2, and the rounded corner r2 at the junction of the small end 1-1 and the big end 1-2 of the body 1 is 1.7mm, the threaded hole 1-3-1 of the blind hole 1-3 inside the big end 1-2, the thread of the threaded part 2-1 of the propulsion shaft is a circular thread, the root fillet radius r3 is 0.6mm, and the convex pin 4 The diameter d is 1mm.

[0034]According to the design of this embodiment, 2arctg ((l-b) / z)=15.8°, α is 16.5°, which meets the requirement of α≥2arctg((l-b) / z), so that the protruding pin 4 is pushed into the bone installation hole on the porous metal rod When the through hole 1-3-3 on ...

Embodiment 2

[0036] For this example see Figure 8 , similar to Example 1, the difference is that the large end 1-2 of the porous metal rod body 1 gradually decreases in diameter through the transition part 1-4 and transitions to the small end 1-1, the material used is metal niobium, and the diameter of the protruding pin 4 is d is 2mm, the porosity of the prepared porous niobium is 85%, and the pore diameter is 450µm-600µm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com