Double-head drilling and tapping machine capable of reducing temperature

A tapping machine and drill technology, which is applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc., can solve problems such as affecting drilling accuracy, products that do not meet the requirements, and reducing product qualification rates. Achieve the effect of improving the pass rate, less labor participation, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

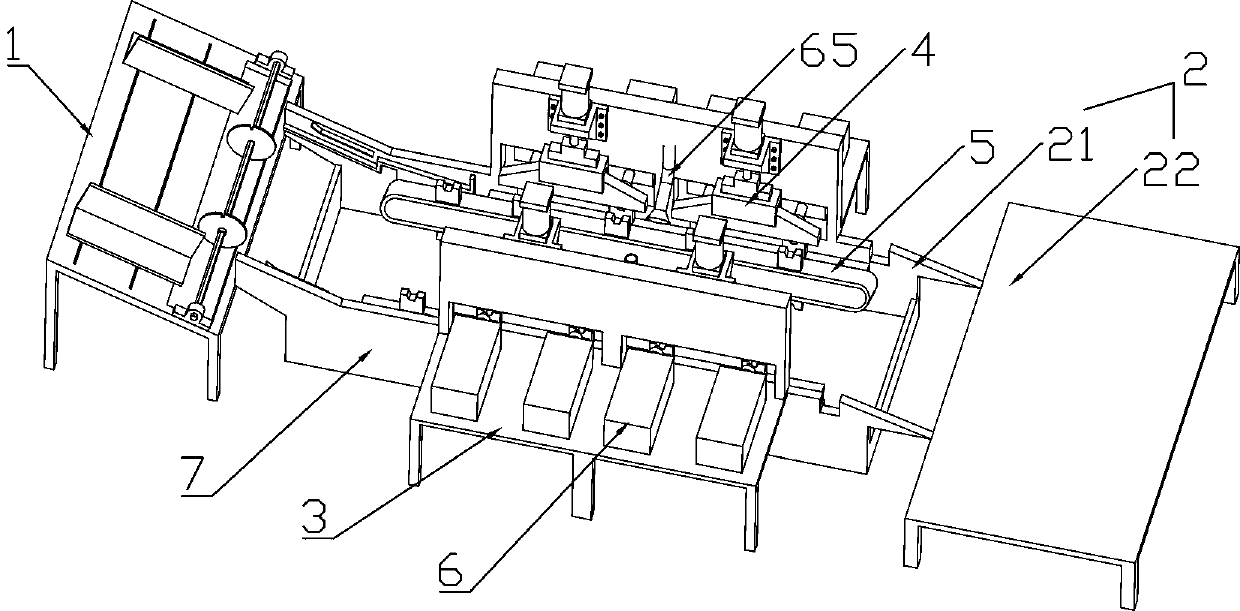

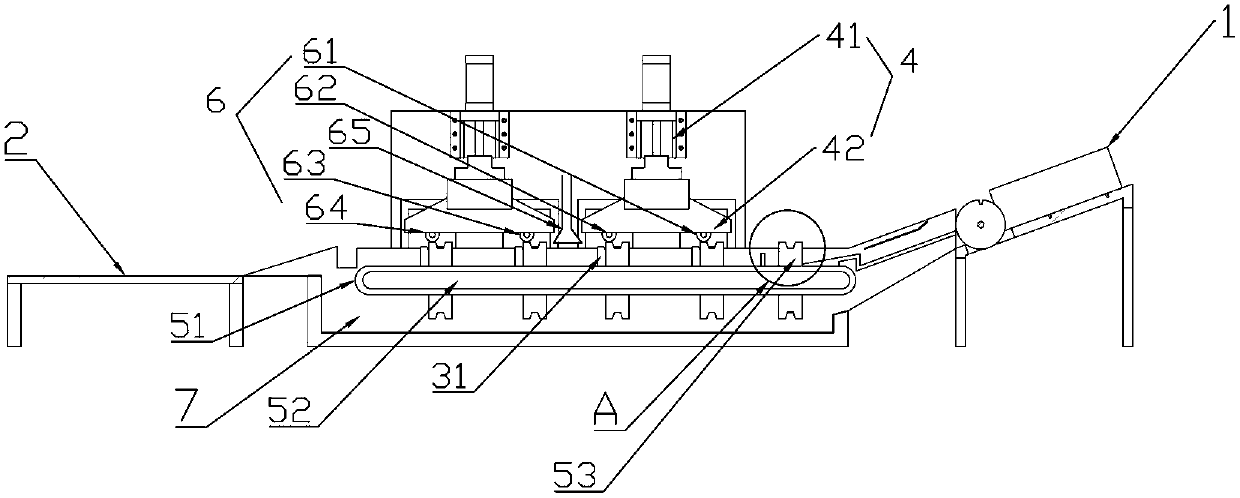

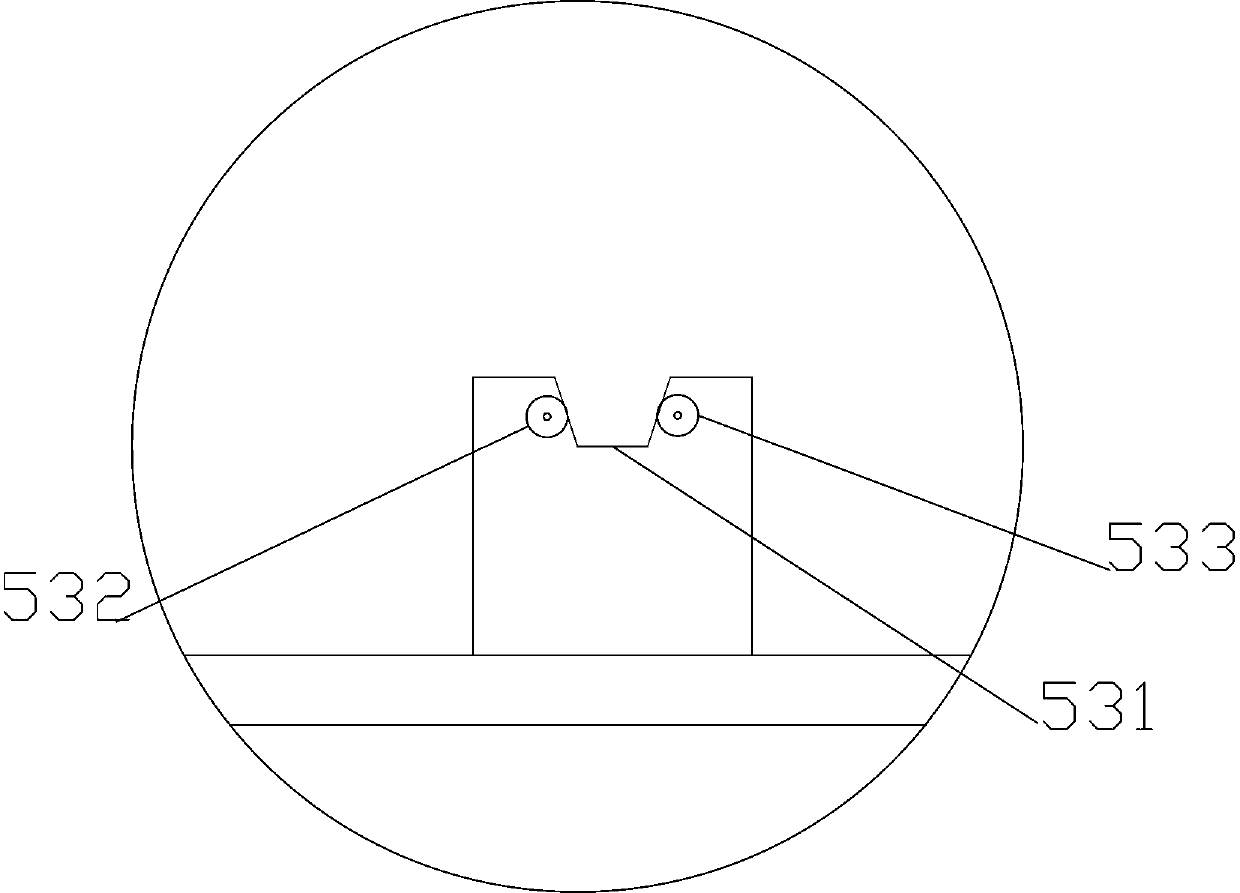

[0032] Example 1, such as figure 1 , figure 2 and Figure 4As shown, a cooling double-head drilling and tapping machine includes a feeding device 1 for feeding objects to be processed and a discharging device 2 for removing processed objects, and also includes a workbench 3 located on the workbench 3. Up and down in the vertical direction, the pressure stabilizing device 4 used to press the object during processing, the material moving device 5 used to move the object to different processing positions, and the processing device 6 arranged on the workbench 3, the processing There are two sets of devices 6, located on both sides of the material transfer device 5, and sequentially include a pre-driller 61, a main driller 62, a cooling device 65, a tapper 63 and a chip blower in the direction close to the discharge device 2 64. Define the vertical direction as up and down, the conveying direction of the object as front and rear, the front close to the feeding device 1, the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com