Self-cleaning spiral extrusion filter and use method thereof

A screw extrusion and filter technology, which is applied in fixed filter element filters, chemical instruments and methods, filtration and separation, etc., can solve the problems of low efficiency, large loss, and many manual operations, and achieve high filtration efficiency and production. High efficiency and low water consumption for backwashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

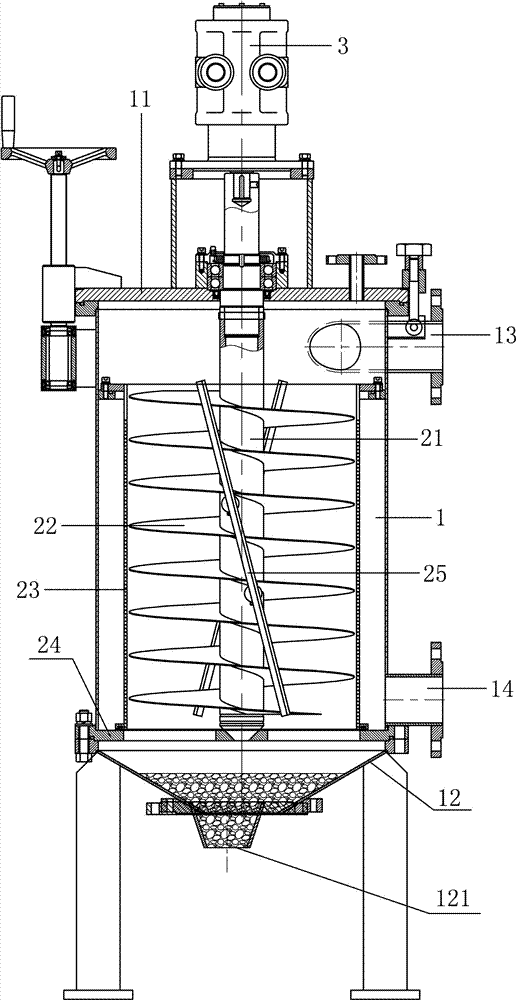

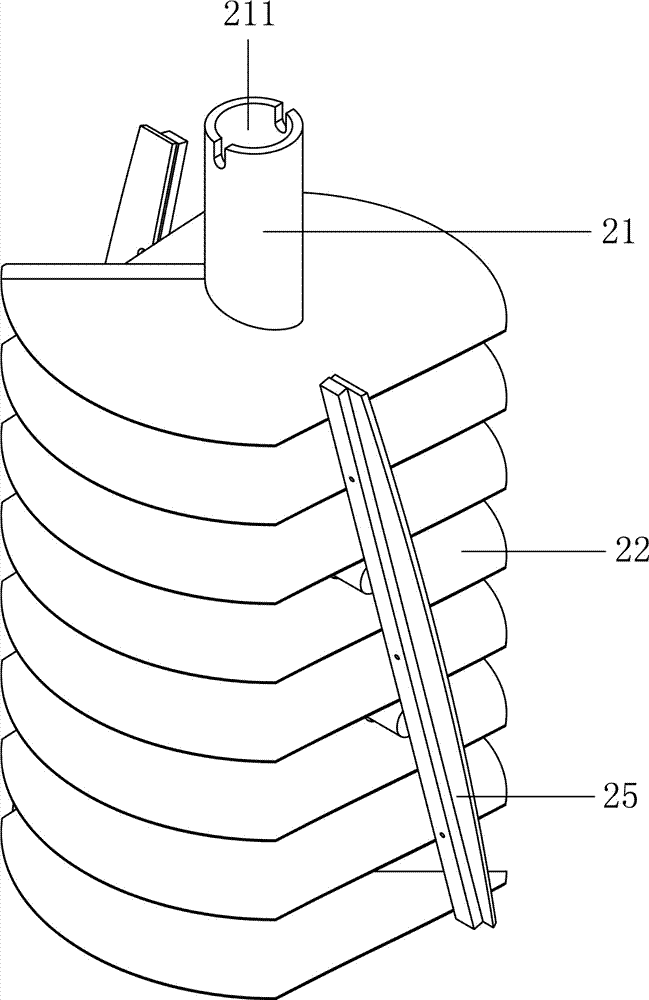

[0027] A kind of self-cleaning type spiral extruded filter, comprises vertical tube 1, vertical shaft 21, vertical helical piece 22, filter screen 23 and motor 3 that are arranged vertically, as Figure 1 ~ Figure 4 As shown, the specific structure is:

[0028] The top and bottom of the vertical tube 1 are respectively covered with a top cover 11 and a bottom cover 12, the bottom of the bottom cover 12 is provided with a discharge port 121, and the upper and lower parts of the outer surface of the vertical tube 1 are respectively provided with an inlet pipe 13 and an outlet pipe 14;

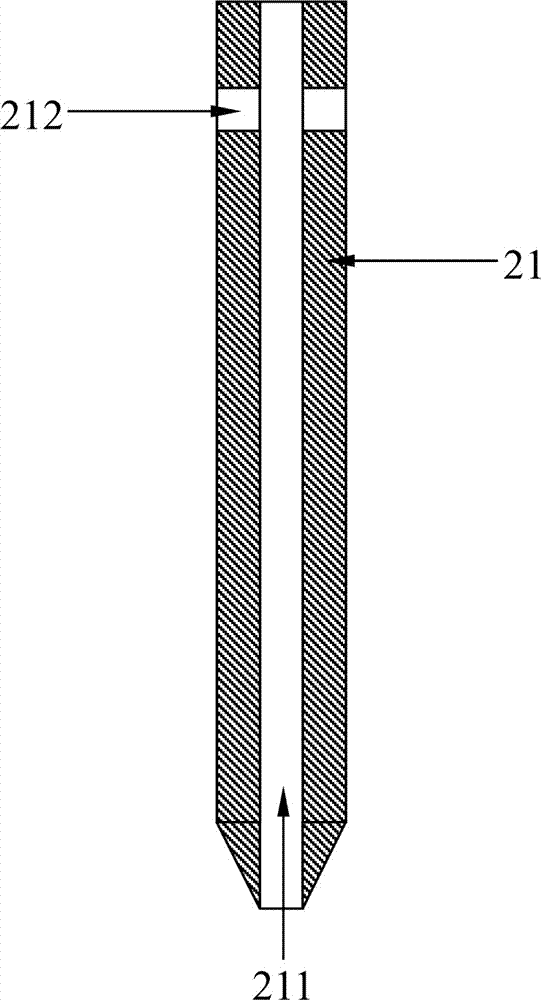

[0029] The vertical shaft 21 is vertically arranged in the vertical tube 1, and the central axes of the vertical shaft 21 and the vertical tube 1 coincide with each other. The top of the vertical shaft 21 is rotatably arranged in the top cover 11, and the outside of the vertical tube 1 is provided with a motor 3 , the output shaft of the motor 3 is connected to the vertical shaft 21 through a tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com