Rail beam type thermal centering machine

A centering machine and beam-type technology, applied in the direction of guiding/positioning/alignment devices, metal rolling, etc., can solve the problems of occupying production cycle, affecting production rhythm, unfavorable perforation, etc., achieving less occupation cycle, fast action rhythm, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The details of the present invention can be understood more clearly with reference to the accompanying drawings and the description of specific embodiments of the present invention. However, the specific embodiments of the present invention described here are only for the purpose of explaining the present invention, and should not be construed as limiting the present invention in any way. Under the teaching of the present invention, the skilled person can conceive any possible modification based on the present invention, and these should be regarded as belonging to the scope of the present invention.

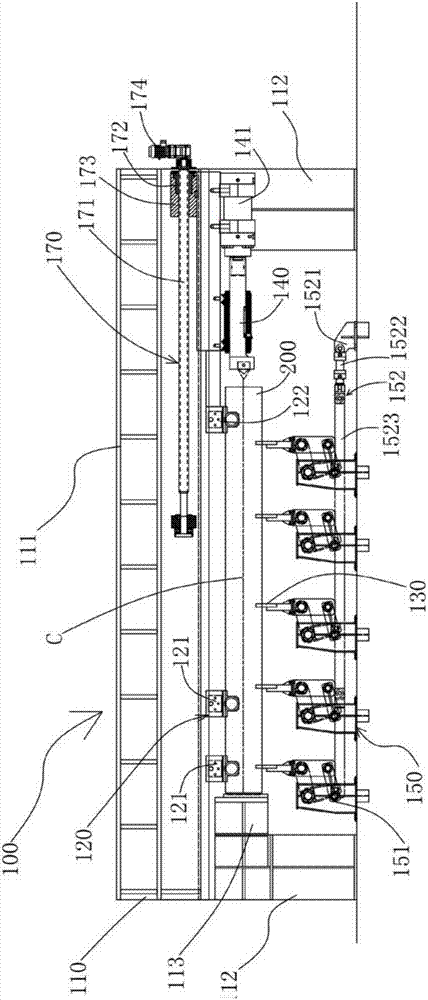

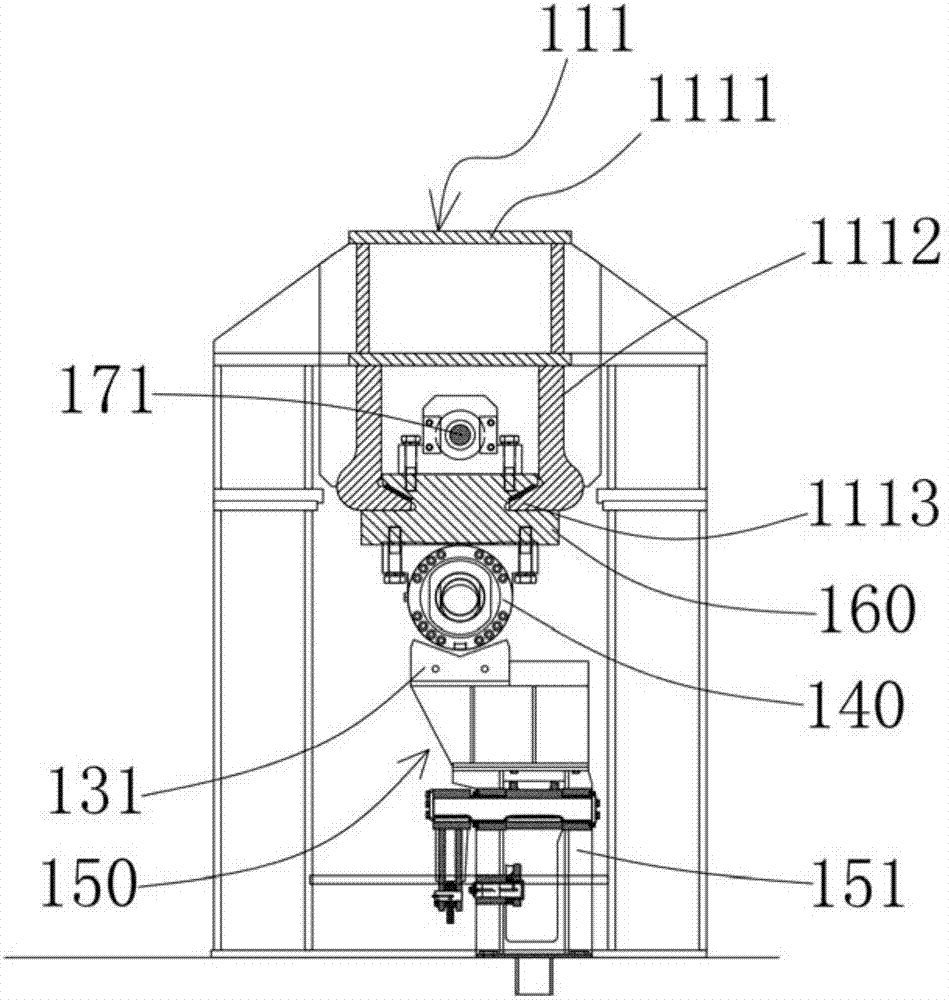

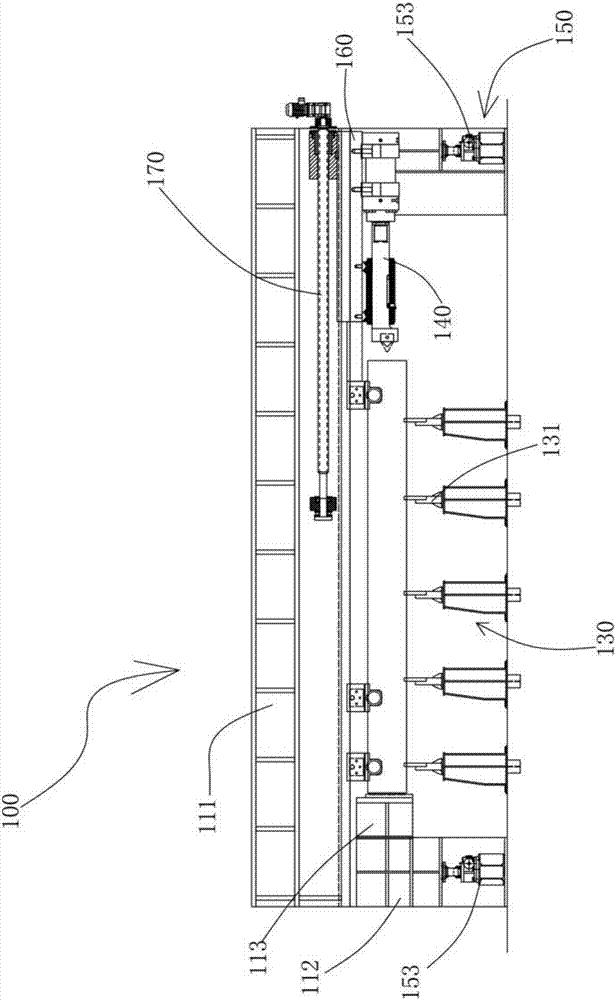

[0068] Please refer to Figure 1 to Figure 16 , the present invention proposes a rail beam type thermal centering machine 100, the rail beam type thermal centering machine includes a frame 110, a stabilizing device 120 installed in the frame 110, a support bracket 130 and a centering device 140, and the frame 110 includes A rail beam 111 arranged horizontally and two sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com