Electric cooker shell machining production line

A production line and rice cooker technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problem of no automatic processing production line, etc., and achieve the effect of reducing the width and reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below according to the accompanying drawings and specific embodiments, but the embodiments of the present invention are not limited thereto.

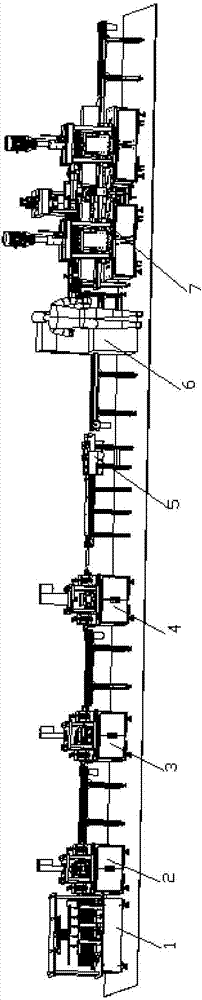

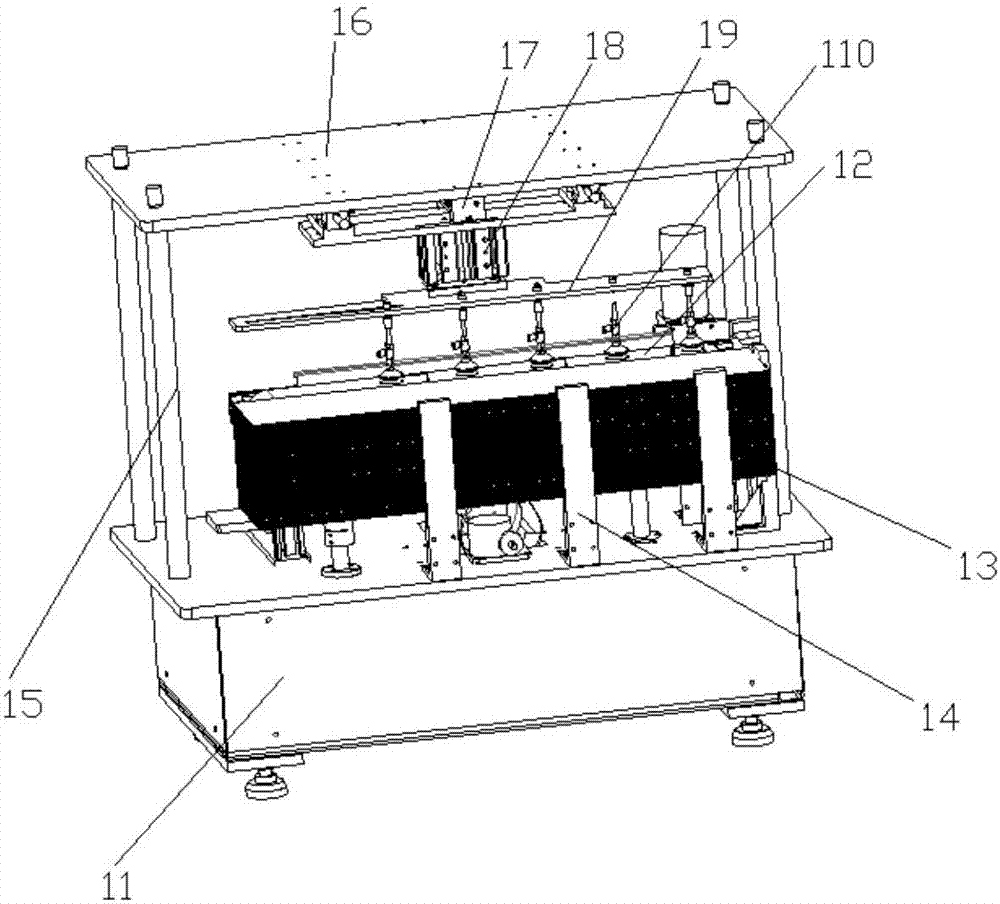

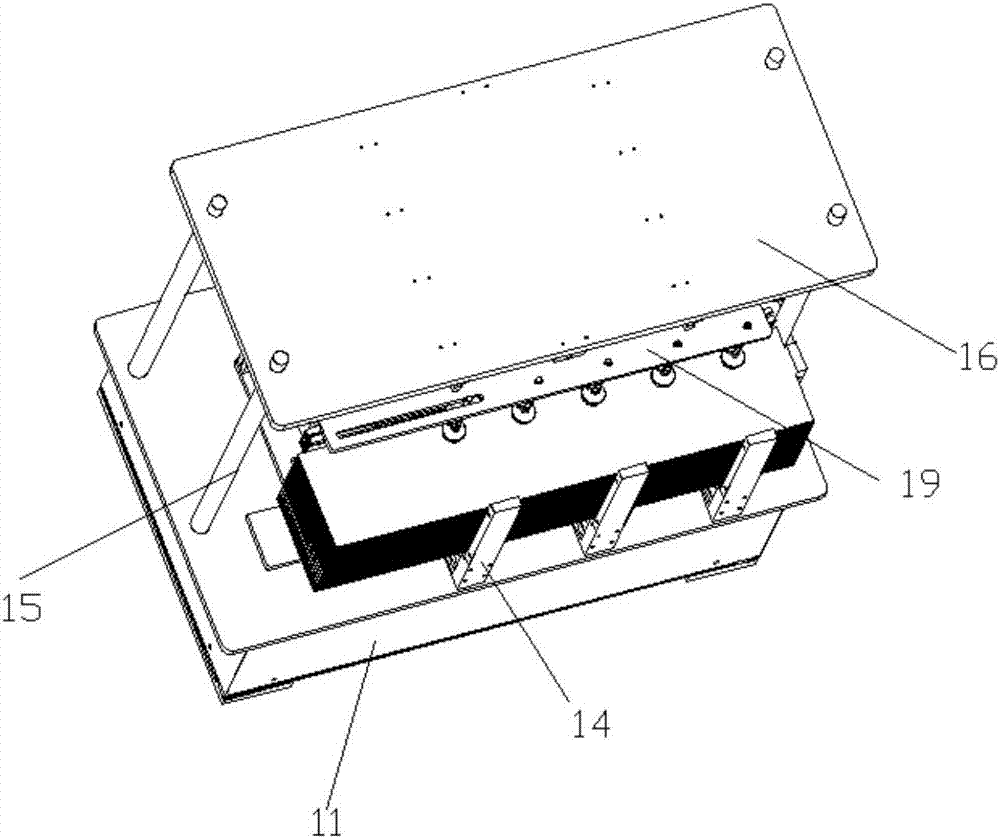

[0049] Such as Figure 1-Figure 10 As shown in the figure, a production line for processing electric rice cooker shells includes a sheet metal material feeding mechanism 1 that adopts vacuum suction cups to absorb and load materials, a notch punching mechanism that continuously punches notches on the metal sheets sequentially, and continuously punches the metal sheets into two groups. Handle hole punching mechanism of the handle hole group 3, furnace hole punching mechanism for punching the middle part of the metal plate out of the furnace hole hole 4, pre-crimping mechanism for pre-curling the edges of both sides of the metal plate 5, manual notch fastening station 6 and the automatic circle guide and crimping mechanism 7, the metal sheet is conveyed vertically, and when the notch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com