Method for constructing plunge milling points for corner plunge milling

A construction method and corner technology, applied in metal processing equipment, metal processing mechanical parts, milling machine equipment, etc., can solve the problems of complicated plunge milling points, low processing efficiency, low corner program processing efficiency, etc., to save plunge milling The effect of cutting tool position and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is based on the CAD / CAM system platform and realizes a method for constructing plunge-milling points for corner plunge-milling. The implementation examples of the present invention are described in detail below in conjunction with the accompanying drawings. This implementation example is implemented on the premise of the technical solution of the invention, and detailed implementation methods and specific implementation processes are provided, but the protection scope of the present invention is not limited to The following implementation examples. The present invention implements detailed steps as follows:

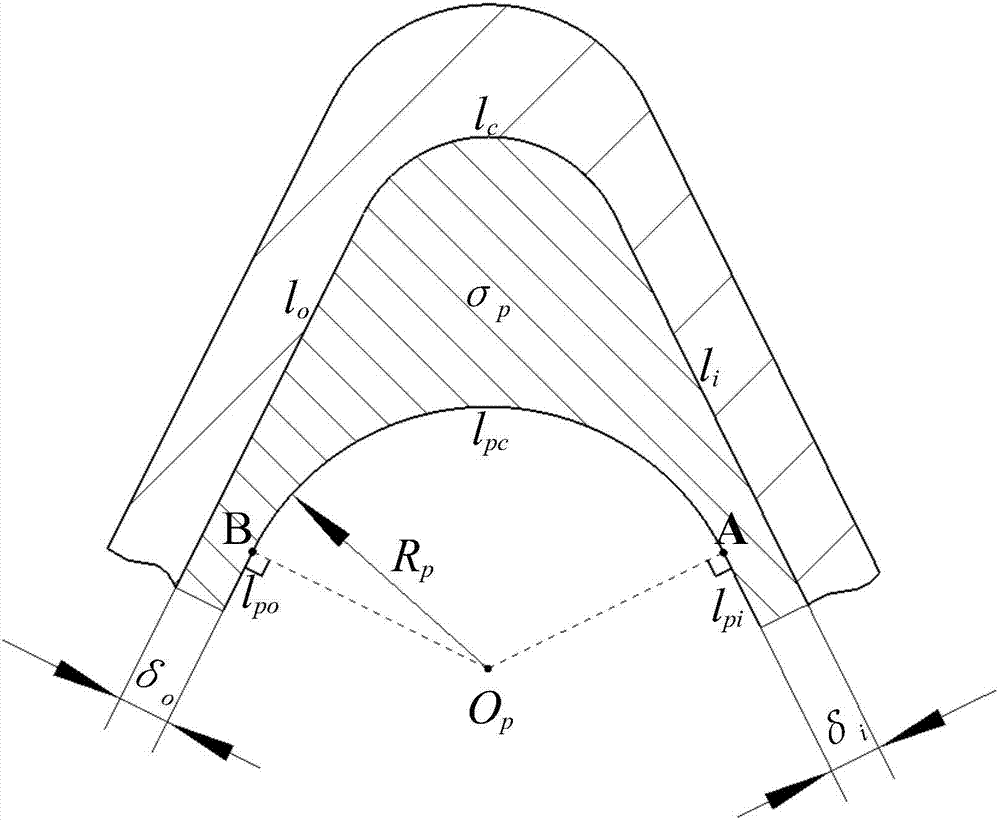

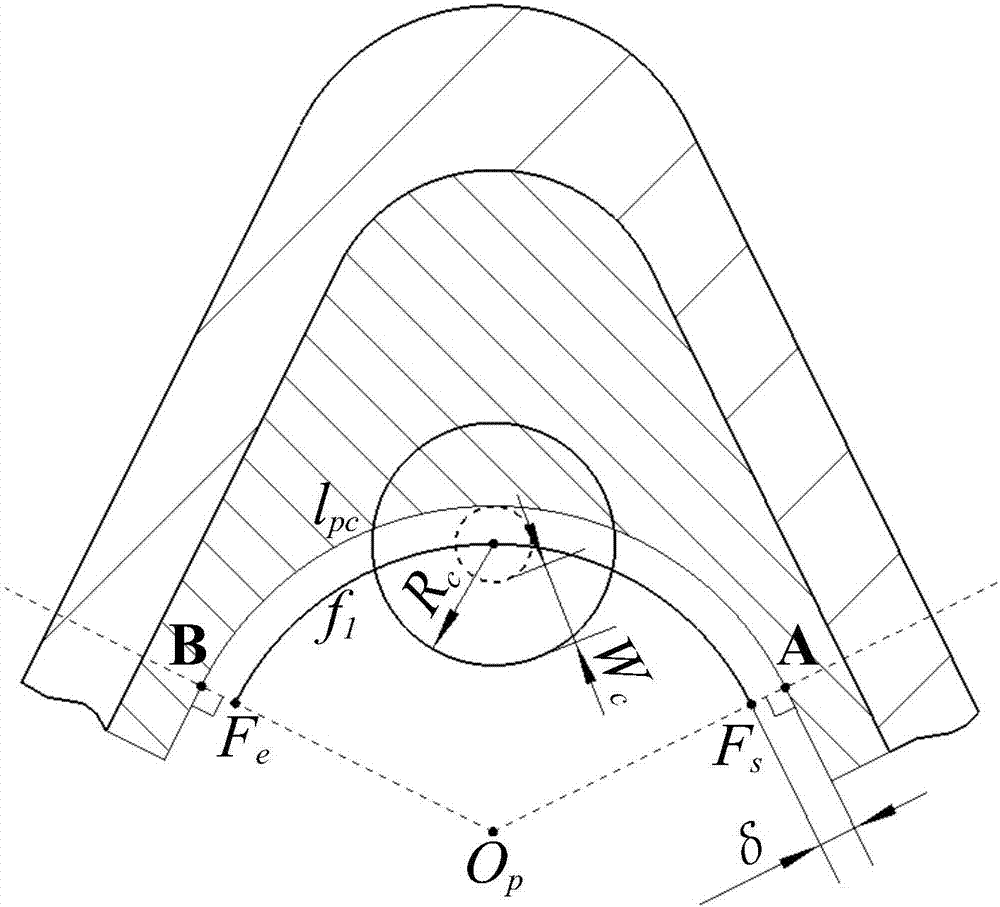

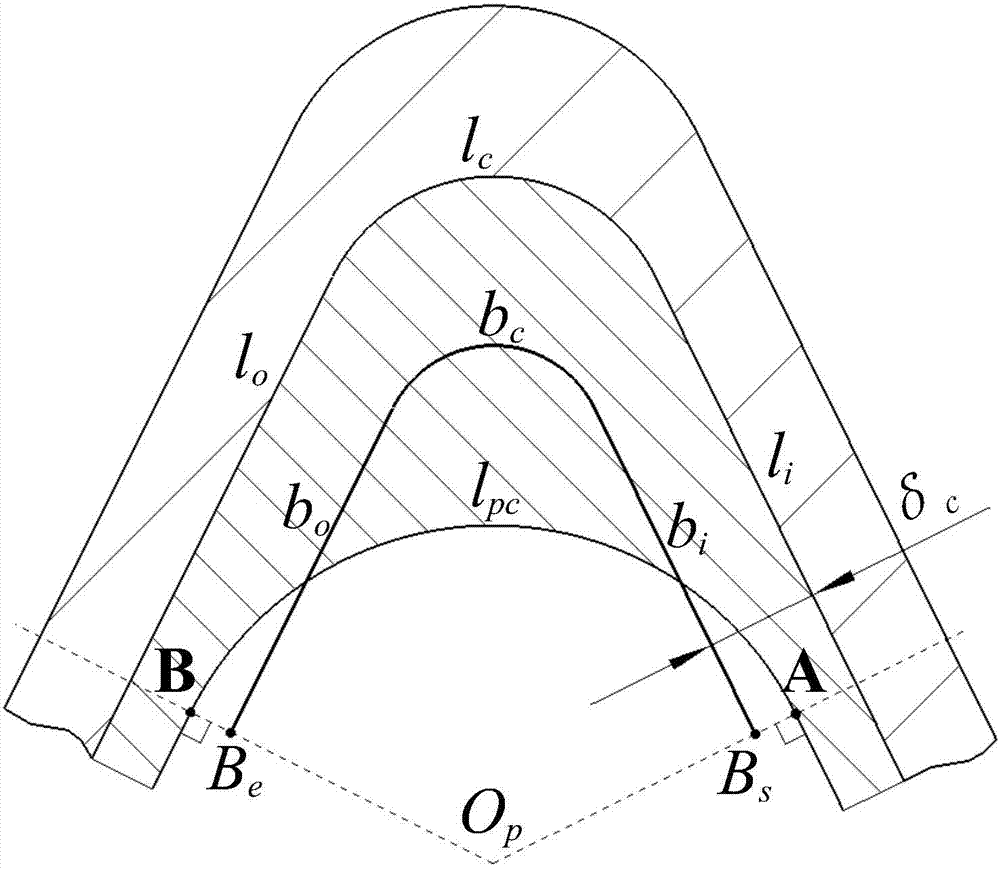

[0023] 1) Construction of corner residual area

[0024] (1) Cut the corner into the end contour line l i Towards the direction of the center of the corner, the margin of the cut-in end is offset δ i , to obtain the cut-in boundary line l of the cutting tool pi , similarly, the l o Offset margin to the center side δ o , to obtain the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com