Method for synthesizing highly-methylated amino resin through trimethylol melamine

A technology of trimethylol melamine and amino resin, which is applied in the field of environmental protection synthesis, can solve the problems of unfavorable environmental protection discharge, troublesome water treatment, increased treatment process and cost, etc., and achieves the advantages of reducing subsequent filtration requirements and costs, and reducing waste water treatment volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

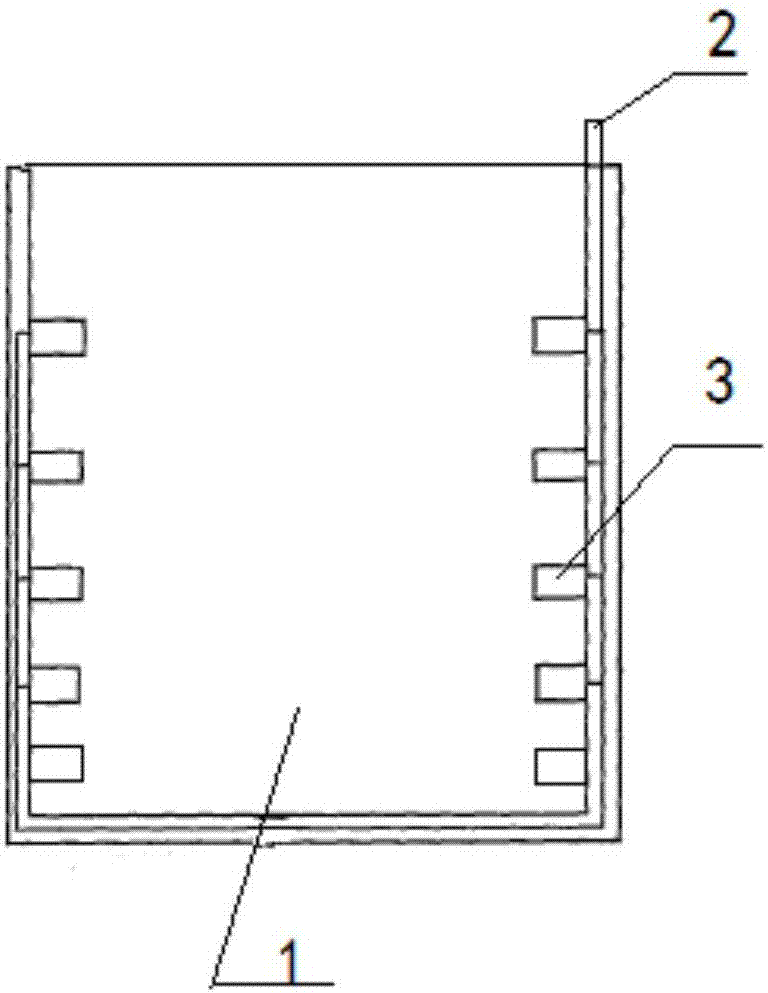

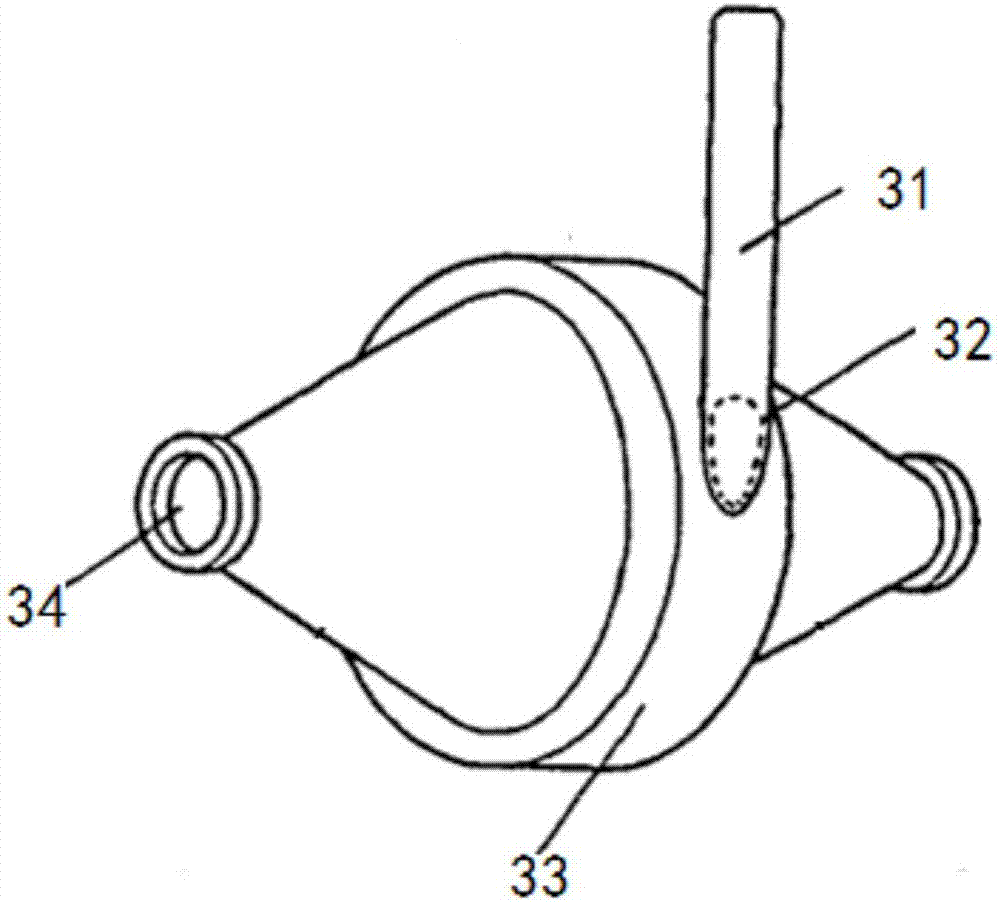

Image

Examples

Embodiment 1

[0029] Using trimethylol melamine as raw material to synthesize highly methylated amino resin:

[0030] (1) According to trimethylol melamine: the molar ratio of methyl alcohol is 1: 20 in above-mentioned reactor, drop into the methanol of above-mentioned metering, adjust reactor stirring frequency converter to 20Hz, add hydrochloric acid and adjust pH value to 3.5, add above-mentioned metering Trimethylol melamine, heating and regulating temperature is 55 ℃ and stirs to make it dissolve;

[0031] (2) after the completion of the reaction after the complete dissolution of trimethylol melamine, keep warm for 2 hours;

[0032] (3) feed ammonia into the reaction kettle through the above-mentioned ammonia gas feeding device, detect the pH value and adjust the pH to be 9;

[0033] (4) Start the vacuum pump, control the vacuum degree to 0.08MPa, the temperature is 60°C, and dealcoholize and dehydrate for 3h;

[0034] (5) Stop vacuuming, add butanol with a mass ratio of 20%, and sti...

Embodiment 2

[0037] Step is with embodiment 1, difference is as follows:

[0038] In step (1), the molar ratio of trimethylolmelamine:methanol is 1:10, the reactor is adjusted to stir the frequency converter to 30Hz, the pH value is adjusted to 5.0 by adding sulfuric acid, and the temperature is raised to 45°C for stirring and dissolving;

[0039] In step (2), keep warm for 1h;

[0040] In step (3), adjust the pH value to 8.0;

[0041] In step (4), the vacuum degree is controlled to 0.09MPa, the temperature is 80°C, and the time is 2h;

[0042] In step (5), 30% butanol was added and stirred for 40 min.

Embodiment 3

[0044] Step is with embodiment 1, difference is as follows:

[0045] In step (1), the molar ratio of trimethylolmelamine:methanol is 1:8, adjust the stirring frequency converter of the reactor to 10Hz, add hydrochloric acid to adjust the pH value to 6.0, and heat up and adjust the temperature to 35°C for stirring and dissolving;

[0046] In step (2), keep warm for 0.5h;

[0047] In step (3), the pH value is adjusted to 8.5;

[0048] In step (4), the vacuum degree is controlled to 0.1MPa, the temperature is 100°C, and the time is 0.5h;

[0049] In step (5), 40% butanol was added and stirred for 20 min.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap