Base end bearing buffer mechanism

A buffer mechanism and base technology, applied in the field of steel structure support structure, can solve problems affecting equipment transportation, suspension base vibration, safety hazards, etc., and achieve the effect of improving buffer effect, avoiding violent vibration, and protecting cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

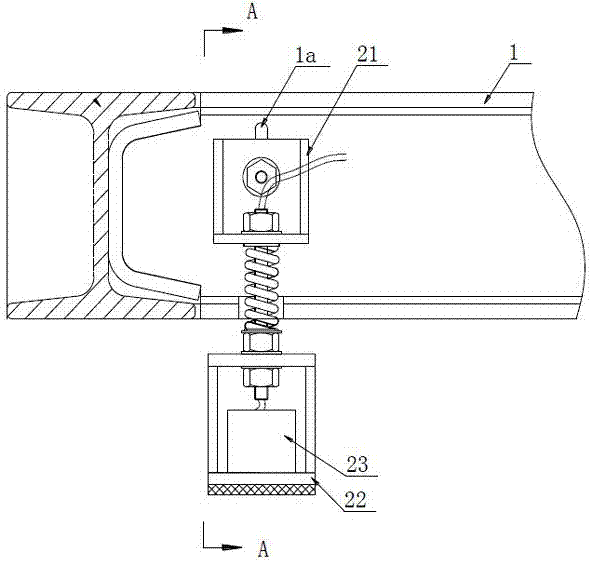

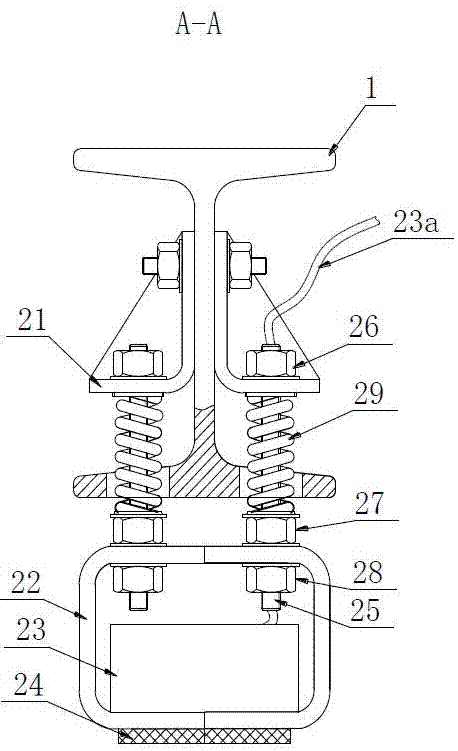

[0012] Such as figure 1 , 2 As shown, the support buffer mechanism 2 at the end of the base is set on the longitudinal I-beam 1 of the suspension base. The longitudinal I-beam 1 includes a web, an upper flange and a lower flange, and the two ends of the web are welded with web The vertical upper and lower flanges of the plate, and the thickness of the upper and lower flanges gradually becomes thinner from the center of the flange to both sides;

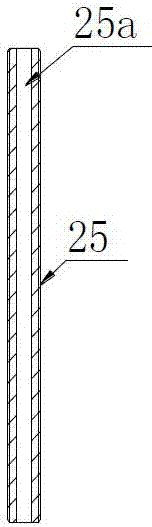

[0013] The base end support buffer mechanism 2 includes a buffer bracket 21, a base support 22, an electromagnetic chuck module 23, a buffer damping pad 24, a buffer screw 25, a first lock nut 26, a second lock nut 27, and a third lock nut 28, buffer spring 29. A pair of buffer brackets 21 are symmetrically arranged on the web of the longitudinal I-beam 1, the buffer bracket 21 is an L-shaped angle steel with a bracket vertical section and a bracket horizontal section, and the angle steel is welded between the bracket vertical secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com