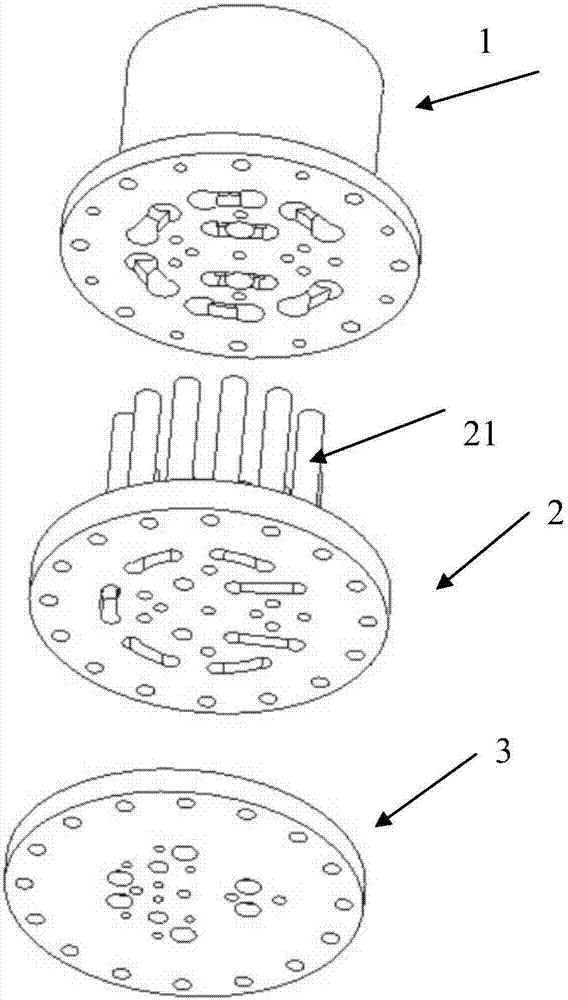

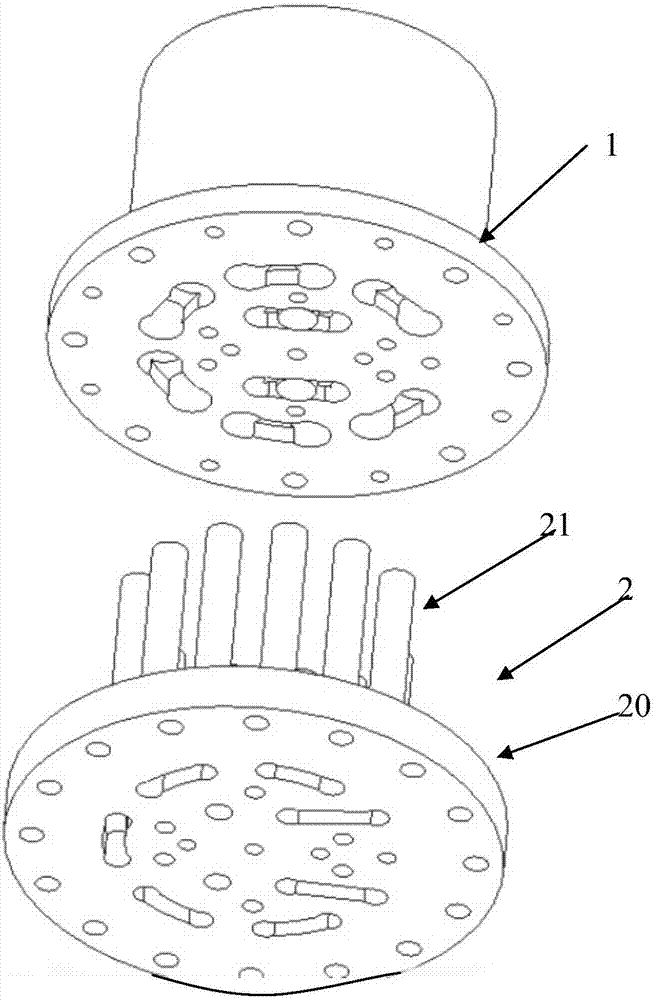

Cooling crucible for vacuum electron beam smelting

A technology of vacuum electron beam and cold crucible, which is applied in the direction of crucible furnace, furnace cooling, furnace components, etc., can solve the problems of high processing cost and affect the reliability of the evaporation system, reduce processing cost, ensure water cooling effect and uniformity, Effect of increased cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment

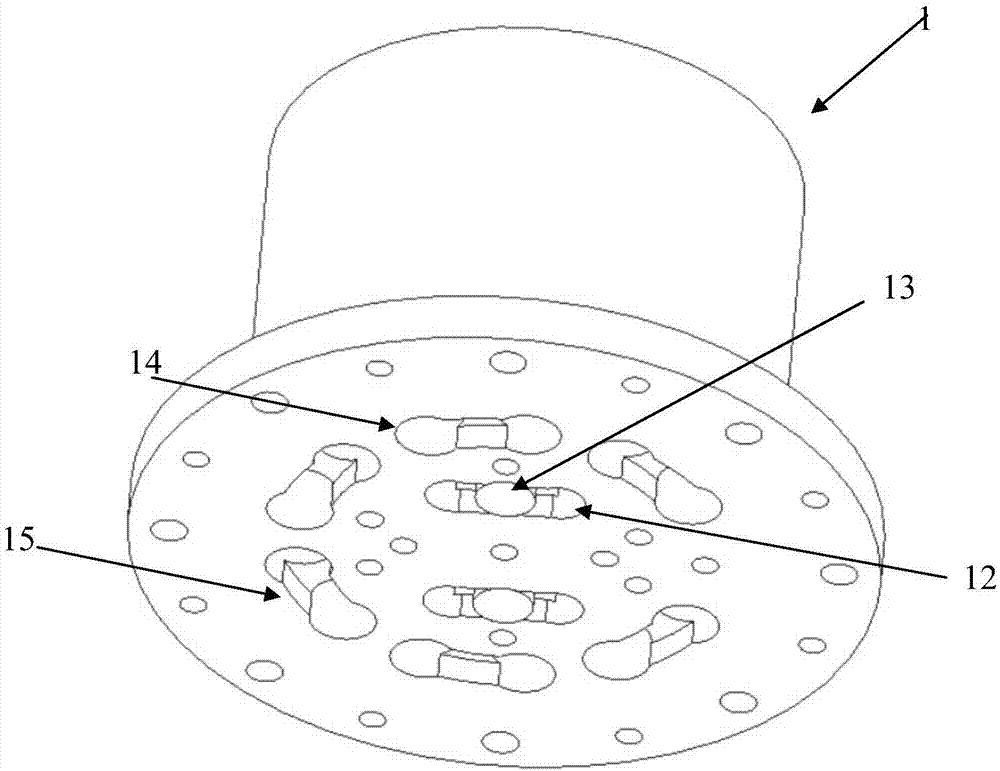

[0047] In order to realize the overall flow path design, the n is an odd number, the water tank is a section of C-shaped water tank, a water guide pipe is connected with the water inlet pipe, one end of the water tank is connected with the water outlet pipe, and a water hole is connected with the other end of the water tank It is connected by connecting parts, and the number of said connecting parts is (n-1) / 2, so as to connect the water guide pipes of the corresponding group. The layout of the C-shaped water tank makes the bottom of the material pool also have more evenly distributed cooling points to achieve bottom temperature control. The flow path of the water-cooling mechanism at the bottom of the material pool is connected in series with the flow path of the water-cooling mechanism around the material pool, and different structural parameter designs are adopted for different parts, so that temperature control can also be realized. Of course, in this embodiment, it is also...

no. 3 example

[0049] The n is an even number, the water tank is a section of C-shaped water tank, the two ends of the water tank are respectively connected with a group of water holes through the connecting part, and the two connecting parts and the water tank constitute the group of water holes. For the connecting groove of the hole, the number of connecting parts is n / 2-1 to connect the corresponding group of aqueducts, and the remaining two aqueducts are respectively connected to the water inlet pipe and the water outlet pipe. The difference between this embodiment and the second embodiment is that the flow path of the water-cooling mechanism at the bottom of the material pool is connected in series to the middle of the flow path of the water-cooling mechanism around the material pool. The rest of the structure is similar to the first embodiment and will not be expanded here. describe.

[0050] Of course, as a further modification of this embodiment, the two ends or one end of the water ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap