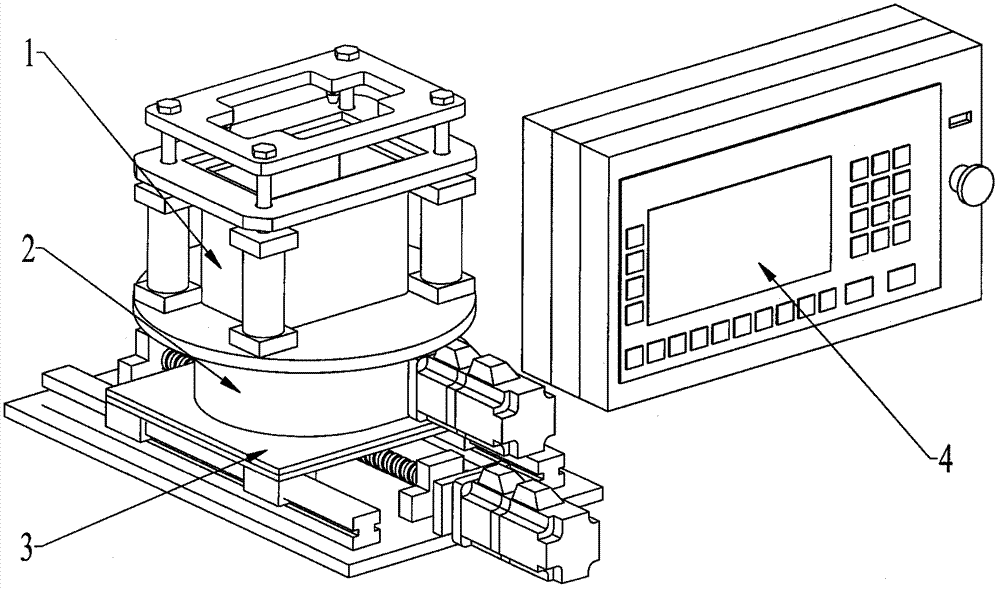

Design and manufacturing of drop hammer type impact clamp capable of adjusting and controlling impact position points in plane

A technology of impact position and drop hammer type, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of quantitative control of impact position points, and the impact performance of materials cannot be fully and truly tested and characterized, so as to reduce irrelevant variables and improve The effect of trial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

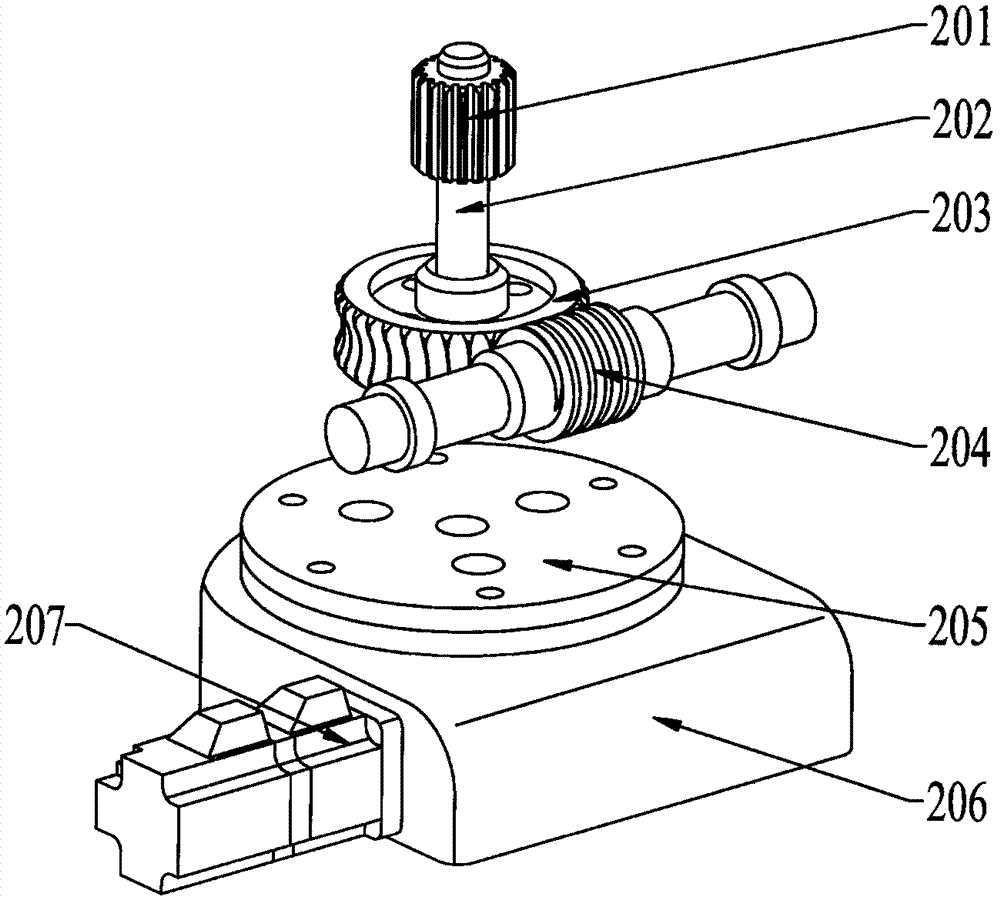

[0051] In this embodiment, a space gear mechanism and a worm gear are selected as the transmission mechanism of the fixed-axis rotating platform. The worm gear mechanism can be regarded as an evolution of the cross-axis helical gear mechanism. The worm and gear mechanism is in line contact, with stable transmission and low noise. When the lead angle is small, the worm gear mechanism is self-locking, that is, it cannot drive when the turbine is active. The worm gear should be made of wear-resistant material. Like the crossed-axis helical gear mechanism, the worm gear mechanism not only slides along the tooth height direction, but also has a large sliding speed along the tooth direction, which is easy to cause heat and wear. Therefore, the worm gear should be made of expensive anti-friction and wear-resistant materials such as copper alloy, and it also needs good lubrication and heat dissipation conditions.

[0052] Such as image 3Shown is a schematic diagram of a fixed-axi...

Embodiment 2

[0054] In this embodiment, the bevel gear of the space gear mechanism is selected as the transmission mechanism of the fixed-axis rotating platform. The bevel gear mechanism is used to transmit motion and power between the intersecting shafts, and the angle Σ between the two shafts can be determined according to needs, and Σ is 90° in the present invention. Bevel gears are divided into straight teeth and curved teeth. Curved bevel gears have stable transmission and large load capacity, and are used in automobiles and tractors. Straight bevel gears are widely used because they are relatively simple to design and manufacture. What selected in this embodiment is a straight bevel gear.

[0055] Such as Figure 10 Shown is a schematic diagram of a fixed-axis rotating platform with a straight-toothed bevel gear mechanism as the transmission mechanism, which consists of a center wheel 201, a transmission shaft 202, a horizontal straight-toothed bevel gear 210, a vertical straight-...

Embodiment 3

[0057] In this embodiment, a space gear mechanism with crossed-axis helical gears is selected as the transmission mechanism of the fixed-axis rotating platform. Cross-axis helical gear transmission is also called helical gear transmission. As far as its single gear is concerned, it is a helical gear. It is different from external meshing parallel shaft helical gear transmission. The helix angle of the two wheels is not necessarily equal, and the direction of rotation is not necessarily the same. on the contrary. Therefore, after installation, it becomes a transmission between space interlaced shafts. Compared with spur gears, helical gears generate less shock and vibration, and the meshing stability is much better than that of spur gears. Due to the large coincidence degree of the helical gear, the total length of the contact line is large, and the load-carrying capacity of the gear is high. Helical gears have a smaller minimum number of teeth than spur gears, so fewer gears...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com