Sealing system real time controllable derotation flow shock-absorbing device in impeller machinery

A technology of sealing system and vibration damping device, which is applied in the direction of mechanical equipment, vibration suppression adjustment, spring/shock absorber, etc., and can solve the problems that the injection pressure and injection volume cannot be adjusted in real time online

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The real-time controllable anti-swirl vibration damping device of the present invention will be described in detail below in conjunction with the accompanying drawings.

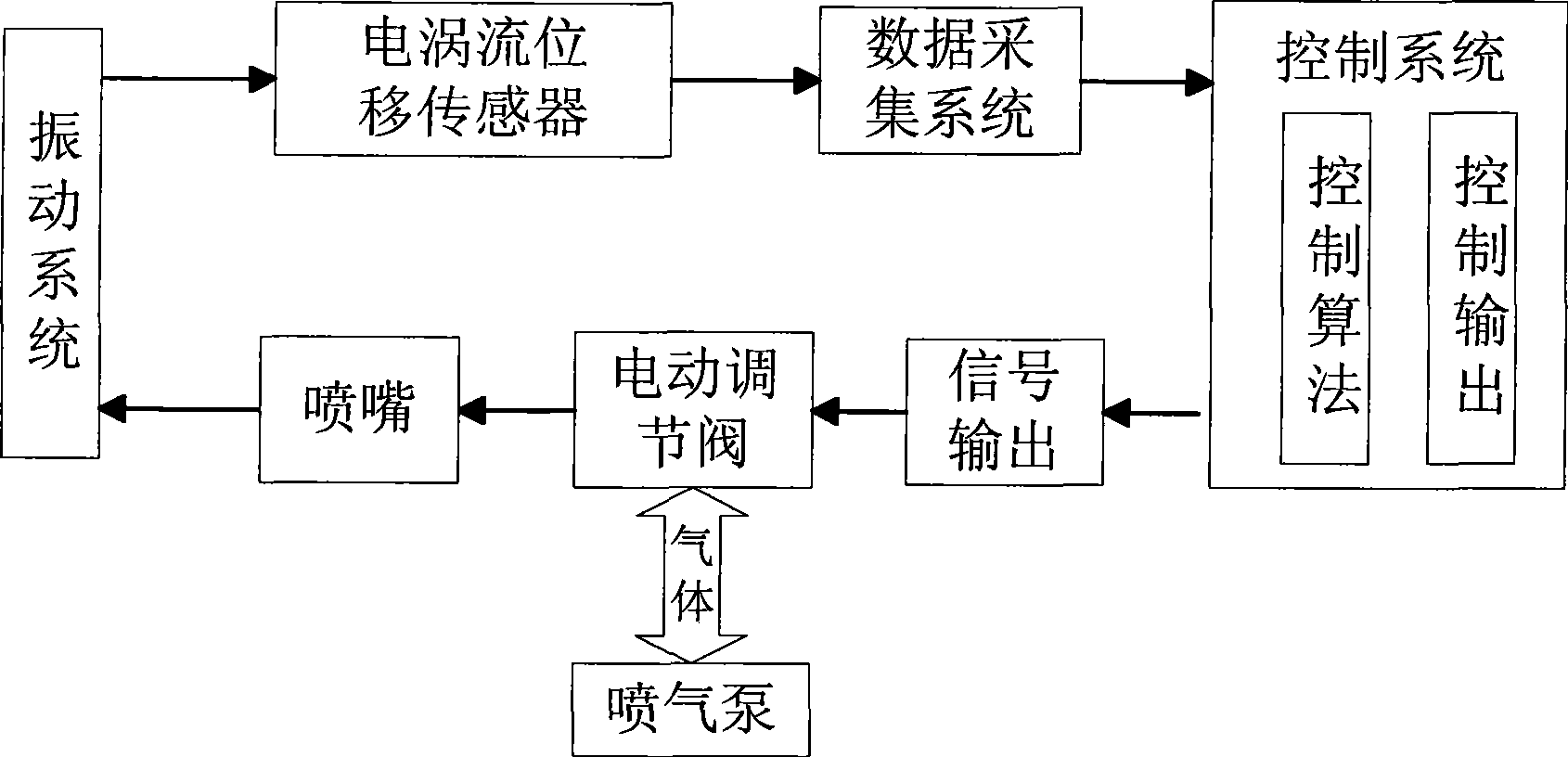

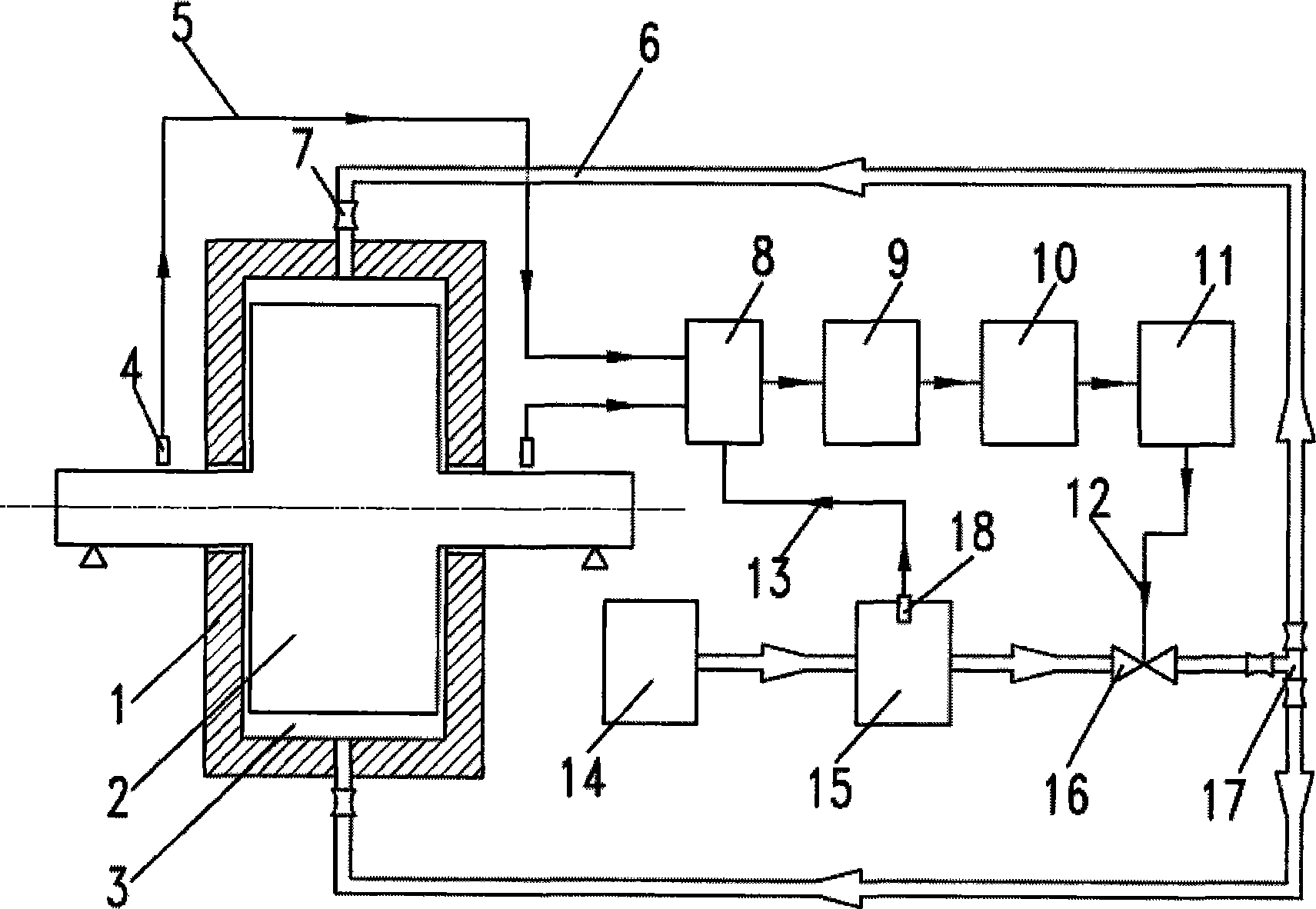

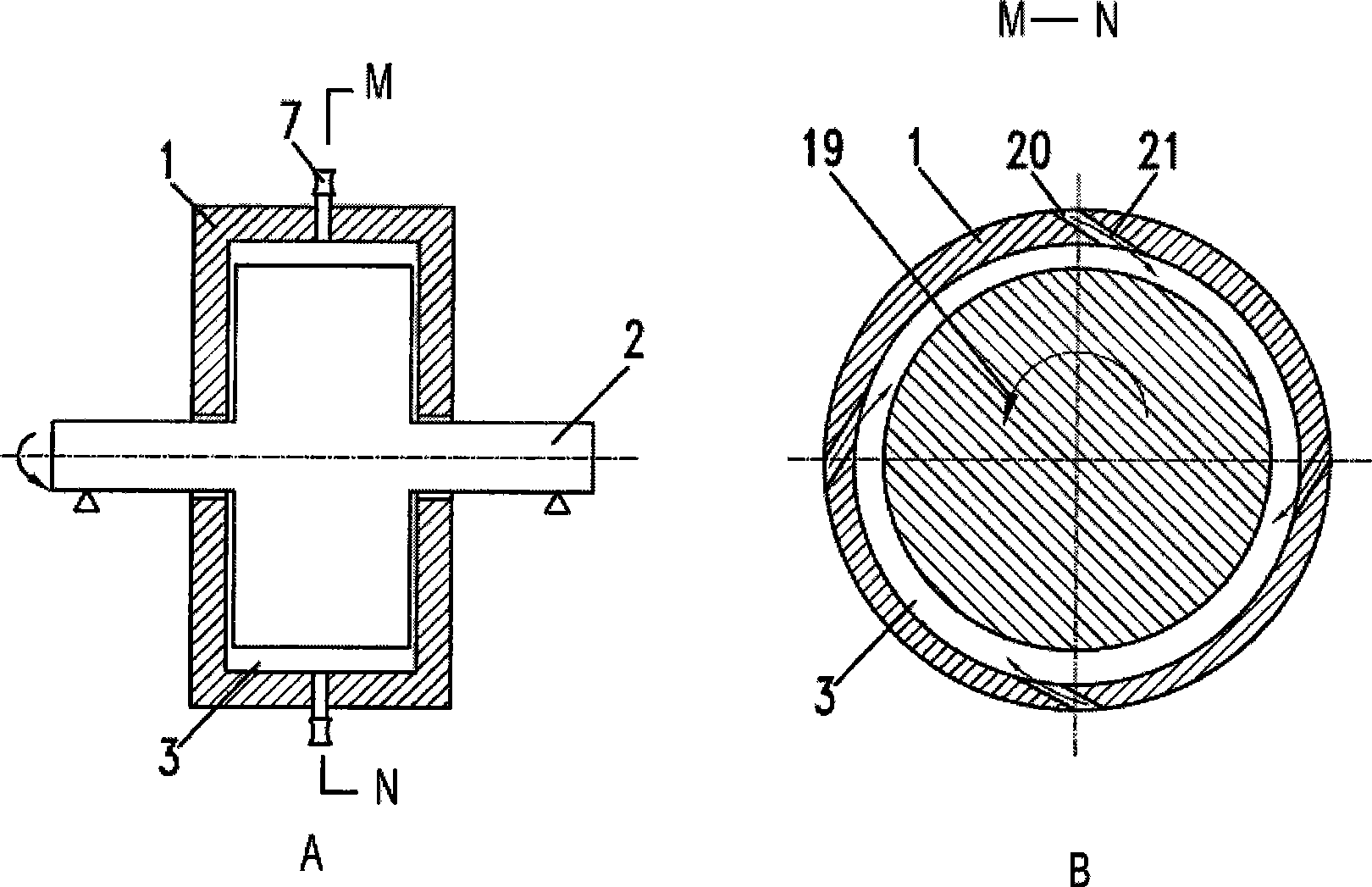

[0038] The present invention is a continuously controllable anti-swirl flow damping device, and an active closed-loop control system for real-time online continuous regulation of anti-swirl flow, as shown in the attached figure 1 shown. The eddy current displacement sensor monitors the vibration of the vibration system in real time, and converts the vibration into an electrical signal that can be collected by the data acquisition system. The data acquisition system performs filtering, amplitude modulation and other processing on the signal, and then inputs the signal into the control system. Calculate and determine the magnitude of the vibration, and give a control signal to control the opening of the electric regulating valve according to the magnitude of the vibration. One side of the electric contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com