Anti-collision knee cap integrally formed by means of pouring and process for producing anti-collision knee cap

An infusion molding and production process technology, applied in protective clothing, clothing, clothing, etc., can solve the problem of not being able to slow down and disperse the impact force, and achieve the effect of weakening the impact force and strengthening the impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

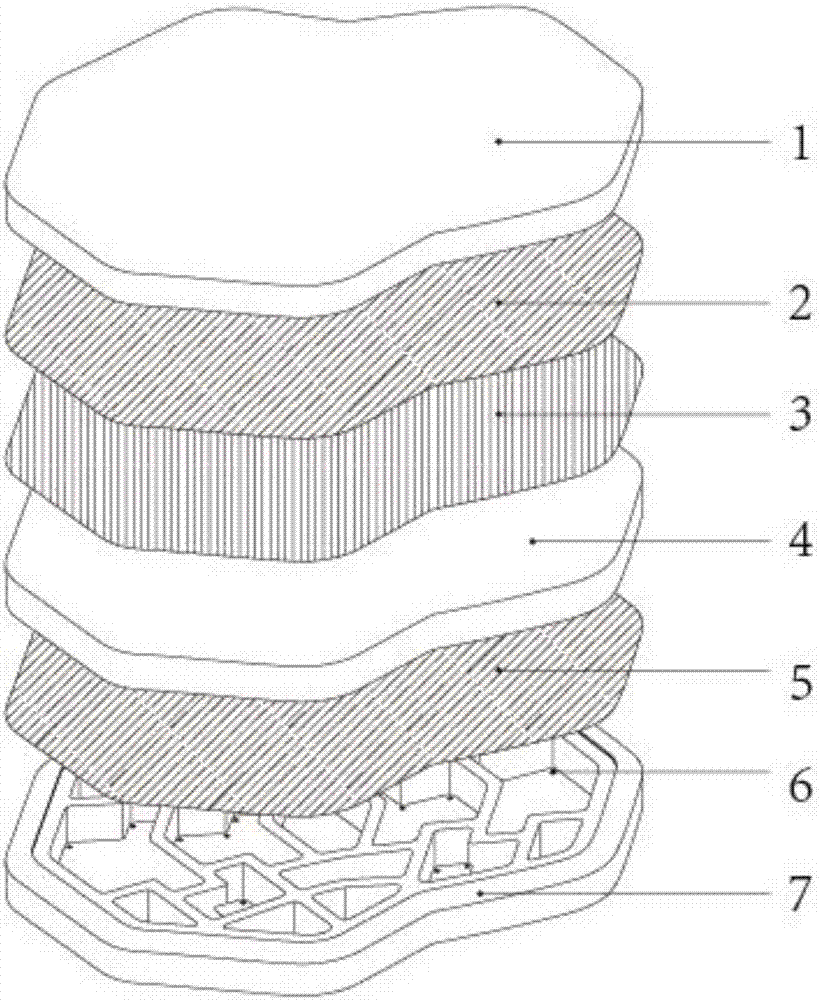

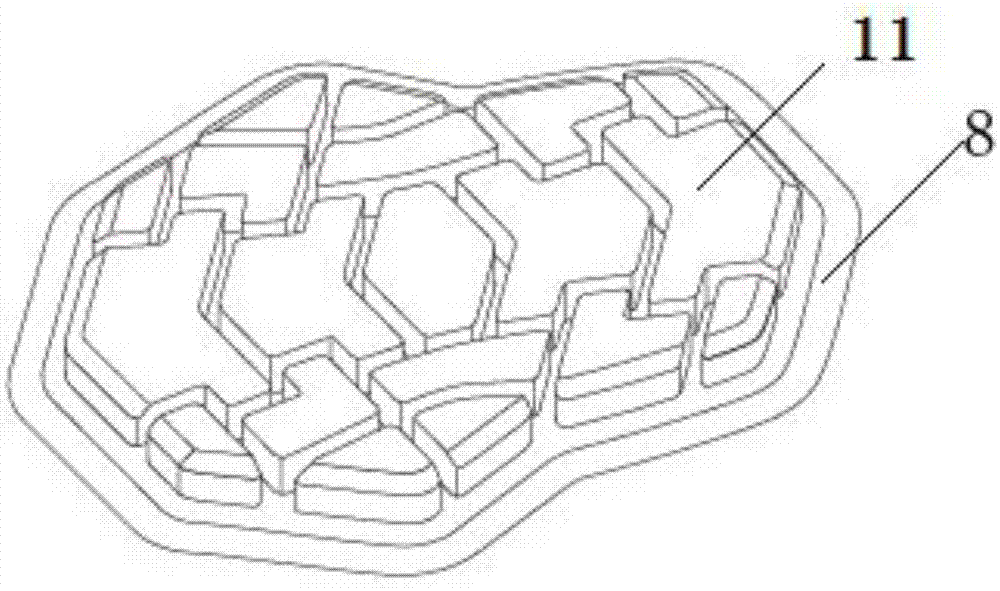

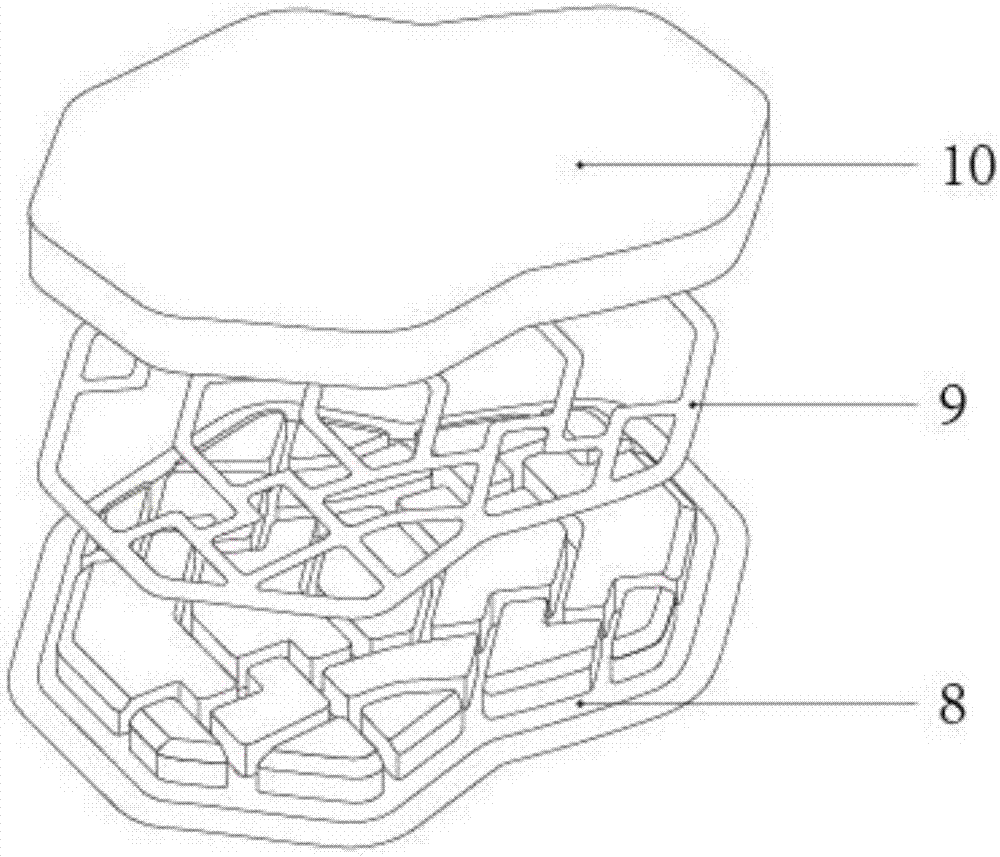

[0032] Such as Figure 1-10 As shown, the integrated infusion-molded anti-collision knee pad includes a knee pad body 12 and a crash pad 8, the crash pad 8 is fixed on the knee pad body 12 through a sewing fixing line 13, and the crash pad 8 sequentially includes an integrally molded textile Cloth 2, upper TPU film 3, PU foam layer 4 and lower TPU film 5, the crash pad 8 includes a plurality of small bump crash pads 11, and the PU foam layer 4 is attached to the upper TPU film 3 and the lower TPU film 5, it will not separate under the huge impact force. The TPU film has high wear resistance and elasticity, can fix PU foam, and can also improve the service life and increase the impact resistance. The lower TPU film 5 can be designed as TPU films of various colors, generally black. After the lower TPU film 5 is formed, it has good wear resistance and improves the service life of the knee pad.

[0033] In this embodiment, the crash pad 8 is also provided with a TPU decorative ...

Embodiment 2

[0035] The production process of the integrated perfusion molding anti-collision knee pad includes the following steps:

[0036] Step 1, put the lower TPU film 5 material on the bottom layer of the bottom mold 7 tooling, the bottom mold 7 tooling is provided with a plurality of grooves, and the bottom of each groove is provided with a vacuum hole 6, through After vacuuming, the material of the lower TPU film 5 is pasted on the bottom mold 7 to form a layer of lower TPU film 5 .

[0037] Step 2, then pour the liquid PU foaming 4 material into the groove of the bottom mold 7, cover the upper layer with TPU film 3 and textile cloth, close the upper mold 1 for foaming, and the liquid PU foaming The temperature is 50-70 degrees Celsius, and the liquid PU foaming time is 10 to 15 minutes.

[0038] Step 3: After forming, press the TPU decorative strip 9 that has been cut with a decorative strip molding tool to form an integrally molded and foamed crash pad 8 . The decorative strip ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com