Coffee maker

A coffee machine and coffee technology, applied in beverage preparation devices, home appliances, applications, etc., can solve the problems of low brewing concentration, affecting taste, and high product manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

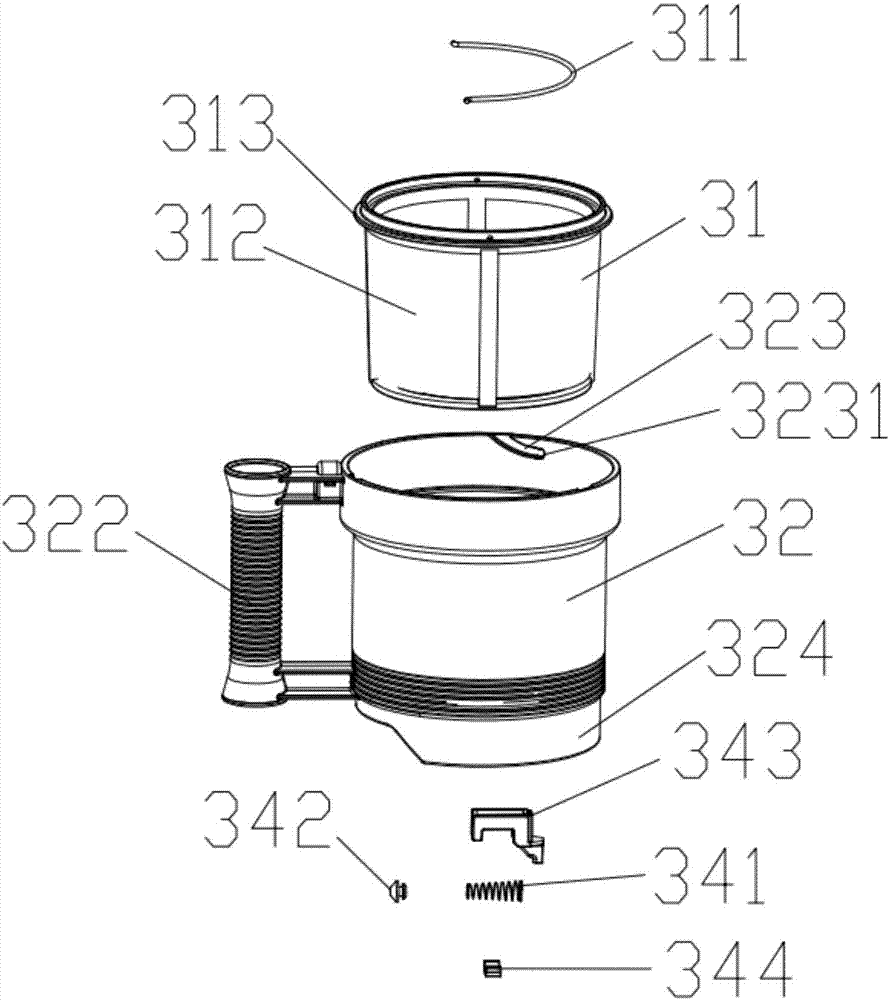

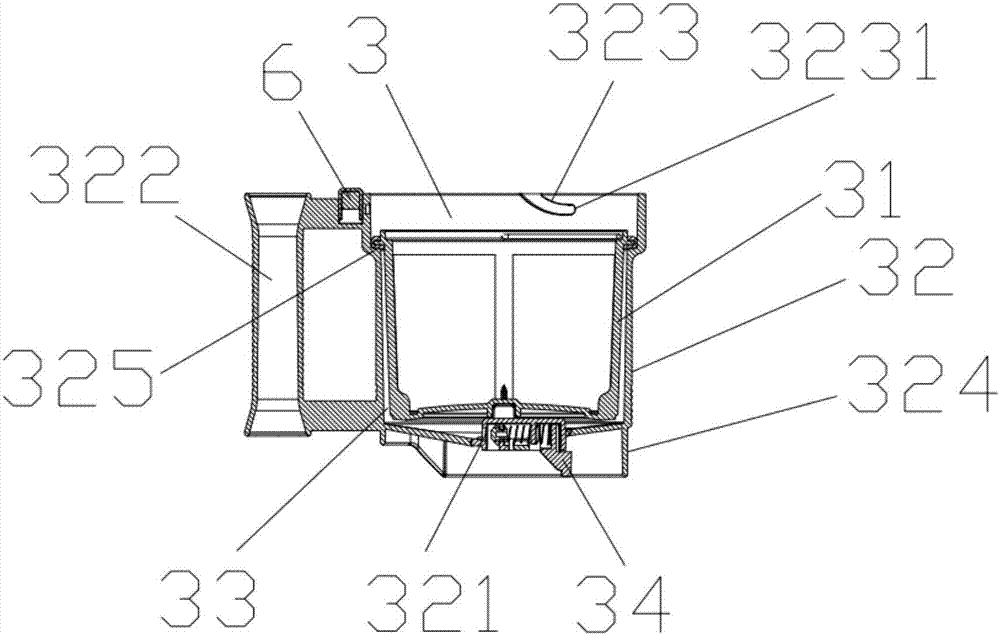

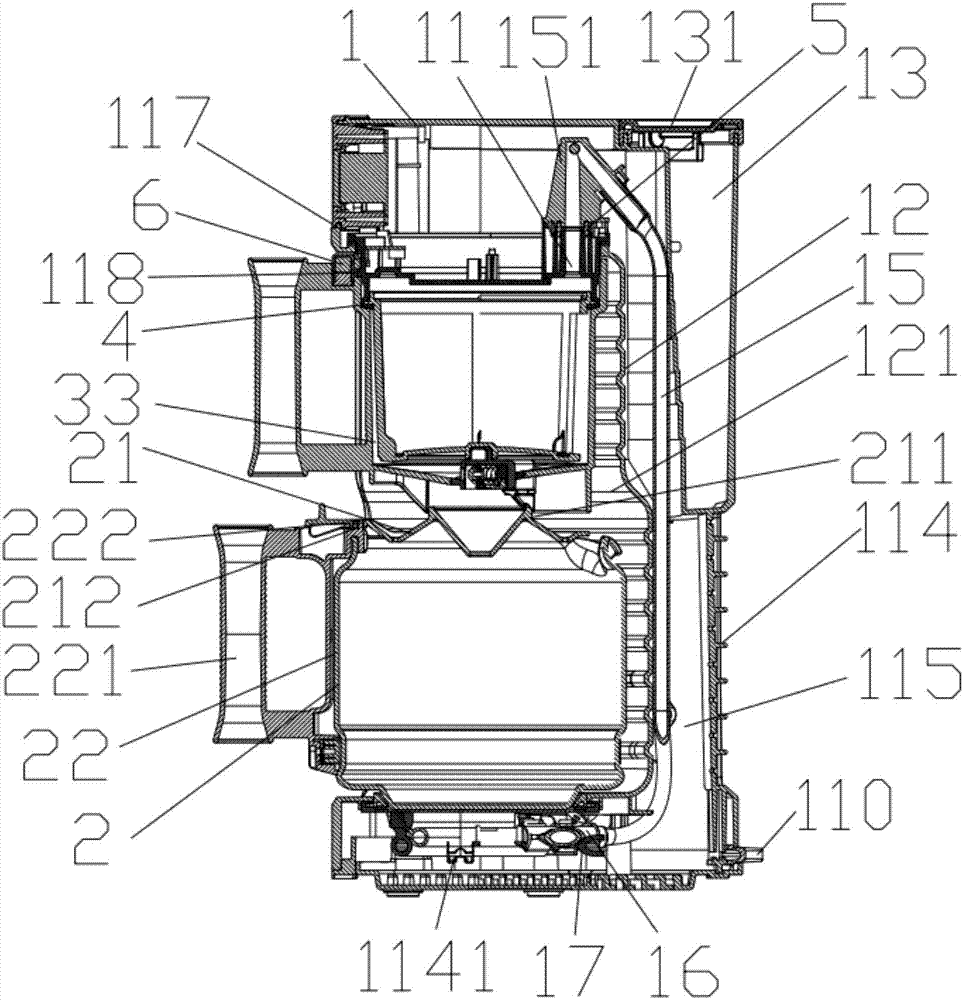

[0114] This embodiment discloses a coffee machine, such as Figure 1~4 , 21, 22, including a main machine 1, a coffee cup 2, and a processing bucket 3, the three are independent of each other, the processing bucket 3 is used for filtering coffee liquid, and the main machine 1 is provided with a first water inlet 11.

[0115] The processing bucket 3 includes an inner bucket 31 and an outer bucket 32 for containing coffee raw materials; There is a first water outlet 321 .

[0116] In this example, if figure 1 As shown, the filter screen 312 is used as the side wall of the inner bucket 31, and it is made of a metal material. It can also be used as the bottom of the inner bucket 31, and can also be made of other materials, such changes all belong to the equivalent protection scope of the present invention.

[0117] When the processing bucket 3 is installed on the main machine 1, the inner bucket 31 fits in the outer bucket 32 and forms a first cavity 33 communicating with t...

Embodiment 2

[0157] This embodiment discloses another coffee machine, which differs in structure from the coffee machine described in Embodiment 1 in that:

[0158] (1) In this embodiment, if Figure 5 As shown, the host 1 is provided with a plurality of lighting indicator lights 7 for prompting that the processing bucket 3 is installed in place and illuminating the inside of the processing bucket 3, and each lighting indicator light 7 is electrically connected with the control circuit board 19; The indicator lights 7 are evenly distributed in the circumferential direction. When the processing bucket 3 is installed on the main machine 1, each lighting indicator light 7 is located above the processing bucket 3 to illuminate the entire transparent inside of the processing bucket 3, so that users can observe the processing bucket 3 at any time. The internal working conditions are more humane.

[0159] (2) In order to provide a more spacious layout space for the circuit that supplies power to...

Embodiment 3

[0163] This embodiment discloses another coffee machine, which differs in structure from the coffee machine described in Embodiment 1 in that:

[0164] In this example, if Figure 6-9 As shown, the processing bucket 3 also includes a bucket cover assembly 35;

[0165] When the processing bucket 3 is installed on the main machine 1, the bucket cover assembly 35 is fastened to the inner bucket 31, and the bucket cover assembly 35 and the inner cavity of the inner bucket 31 form a second cavity 36, and the first water inlet 11 and the second cavity 36 is connected to the water inlet, and the area between the opening of the inner bucket 31 and the opening of the outer bucket 32, and the bonding area between the bucket cover assembly 35 and the inner bucket 31 are all sealed.

[0166] Specifically, in this embodiment, as Figure 6-9As shown, when the processing bucket 3 is installed on the main machine 1, the bonding area between the bucket cover assembly 35 and the inner bucket ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com