Liquid filtering and degassing integration device

A liquid and equipment technology, applied in the field of liquid filtration and degassing integrated equipment, can solve the problem of large space occupation, and achieve the effect of increasing the surface area, ensuring the path and space, and speeding up the filtration speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

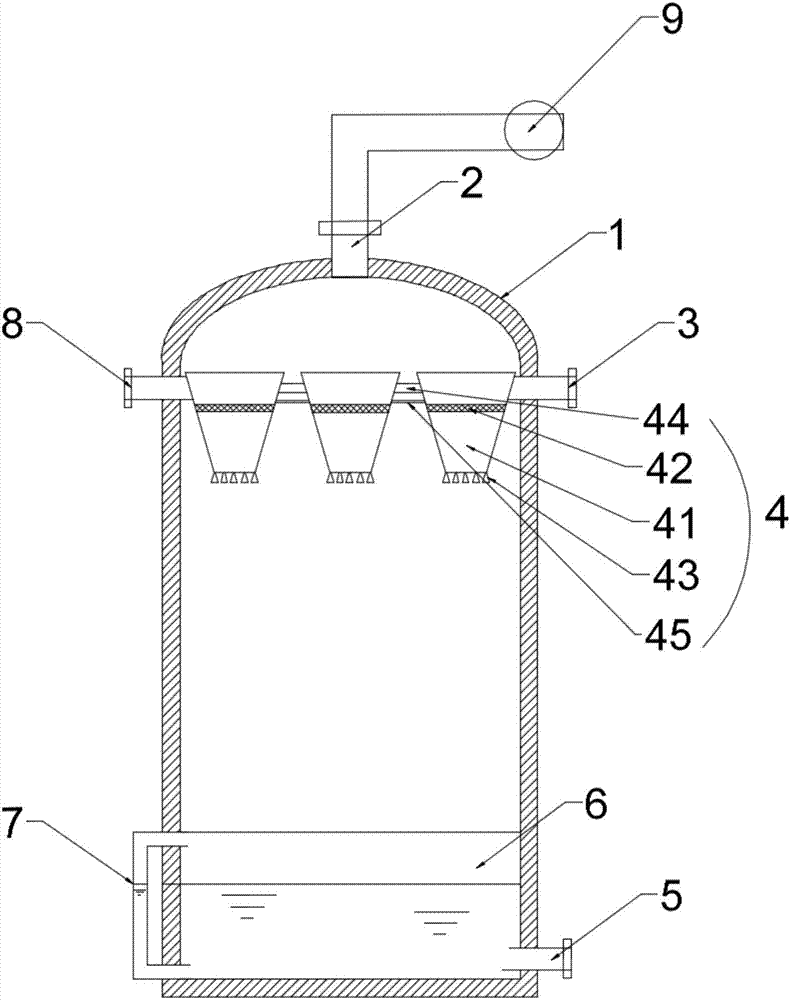

[0030] Such as figure 1 As shown, this embodiment provides an integrated liquid filtration and degassing device, including a tower body 1, a gas outlet 2 on the upper part of the tower body 1, a liquid inlet A3 and a liquid inlet B8, a filter tank assembly 4 inside the tower body, and a tower body 1. The lower liquid storage tank 6, the liquid level gauge 7 connected to the liquid storage tank 6, and the liquid outlet 5 below the tower body. The filter tank assembly 4 includes several filter tanks 41 connected side by side, and the inside of the filter tanks 41 are arranged There is a filter layer 42 , and several nozzles 43 for dispersing liquid are arranged at the bottom of the filter tank 41 , and the liquid inlet A3 and the liquid inlet B8 are respectively connected to the filter tanks 41 at both ends of the filter tank assembly 4 .

[0031] Adjacent filter tanks 41 of the filter tank assembly 4 are connected by hoses 44 , and the hoses 44 are arranged on the upper side of...

Embodiment 2

[0039] Such as figure 1As shown, this embodiment provides an integrated liquid filtration and degassing device, including a tower body 1, a gas outlet 2 on the upper part of the tower body 1, a liquid inlet A3 and a liquid inlet B8, a filter tank assembly 4 inside the tower body, and a tower body 1. The lower liquid storage tank 6, the liquid level gauge 7 connected to the liquid storage tank 6, and the liquid outlet 5 below the tower body. The filter tank assembly 4 includes several filter tanks 41 connected side by side, and the inside of the filter tanks 41 are arranged There is a filter layer 42 , and several nozzles 43 for dispersing liquid are arranged at the bottom of the filter tank 41 , and the liquid inlet A3 and the liquid inlet B8 are respectively connected to the filter tanks 41 at both ends of the filter tank assembly 4 . A certain distance is maintained between the filter tanks 41 of the filter tank assembly 4 and the filter tanks 41 are connected by a hose 44 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com