Roll gap learning coefficient correcting method in roll gap regulating process of hot continuous rolling strip steel precision rolling

A technology of learning coefficient and adjustment process, applied in the direction of rolling force/roll gap control, etc., can solve the problems of reverse learning, small learning amount, affecting strip thickness accuracy, etc., to achieve rapid roll gap adjustment and improve rolling. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

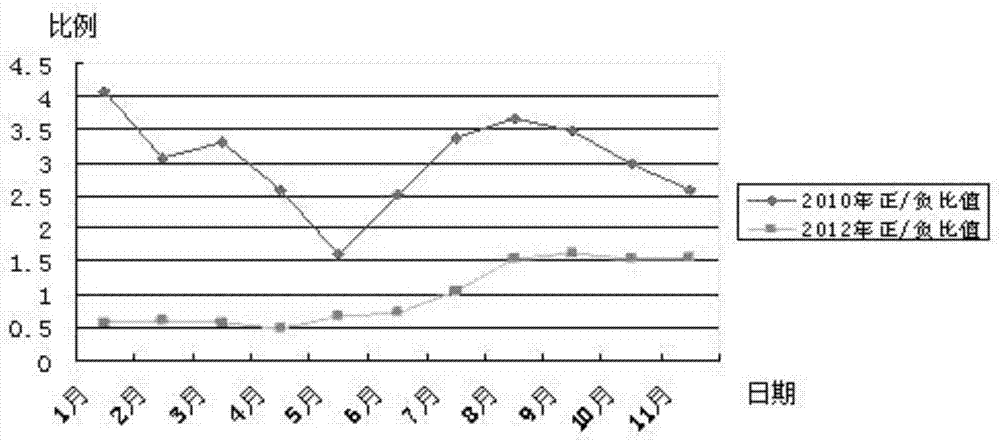

[0060] The 1700 production line of Anshan Iron and Steel Co., Ltd.’s hot-rolled strip steel plant adopts the roll gap setting calculation model and the AGC automatic thickness control system to control the thickness of the strip steel and the thickness of the head and tail. 1.

[0061] Table 1:

[0062] time

Number of rolling blocks

Thickness positive tolerance number

Thickness negative tolerance number

head hit rate

January 2010

11385

1872

459

79.53%

February 2010

9997

1422

465

81.12%

March 2010

8910

1614

487

76.42%

April 2010

7454

1204

464

77.62%

May 2010

11432

1204

752

76.82%

June 2010

11086

1892

750

76.17%

July 2010

11687

2269

671

74.84%

August 2010

12111

2334

636

75.48%

September 2010

9952

1655

478

78.57%

October 2010

11738

2235

756

74.52%

November 2010 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com