Chip removal device for lathe bed of numerical control machine tool

A CNC machine tool and bed technology, which is applied to metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as low production efficiency, large maintenance funds, and machine tool damage, so as to avoid the reduction of processing efficiency, Novel design and thorough cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

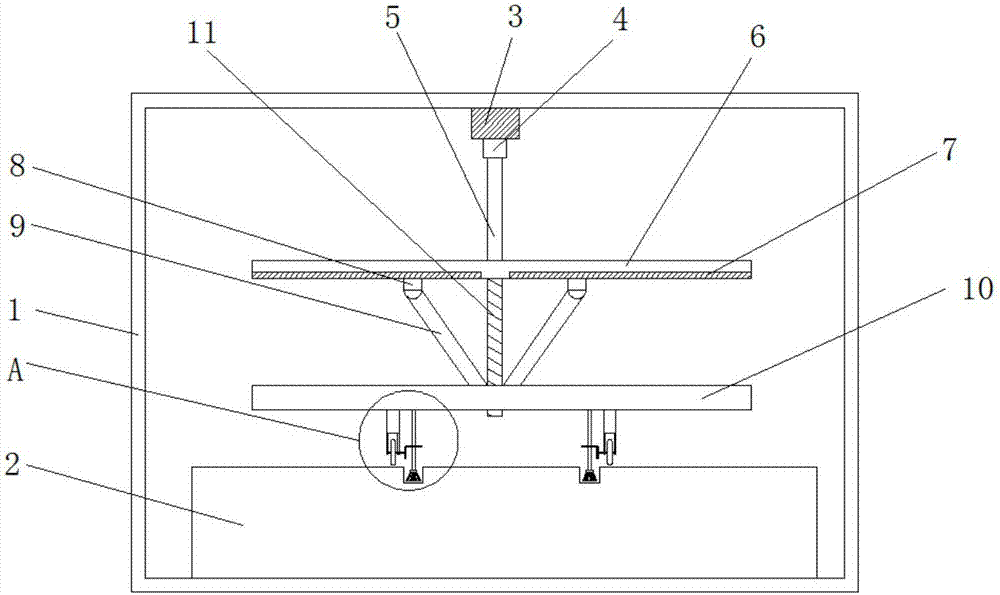

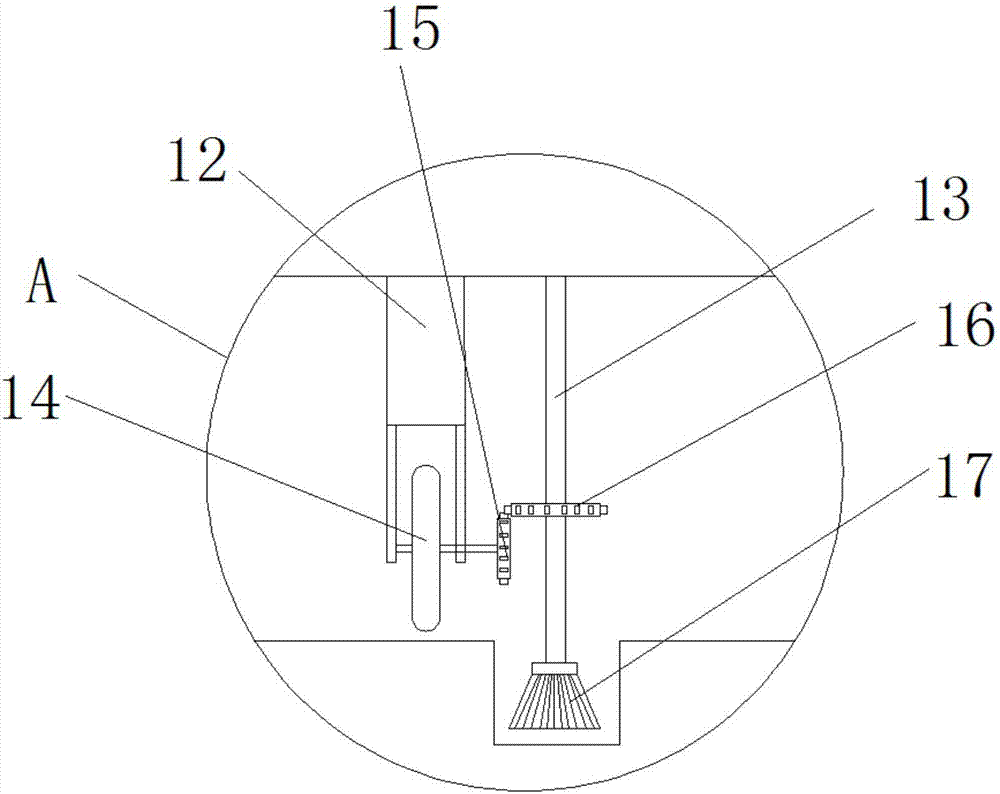

[0017] refer to Figure 1-2 , a chip removal device used on the bed of a numerically controlled machine tool, comprising a machine tool main body 1, a machine bed 2 welded to the bottom of the machine tool main body 1, a track 3 is provided along the width direction at the middle position of the inner wall of the top plate of the machine tool main body 1, and the track 3 is movable and installed There are mobile device 4, mobile device 4, mobile device 4 has mobile wheel and mounting plate, mobile wheel is installed on the mounting plate through bearing, and mobile wheel is movably installed on track 3, mounting plate connects fixed bar 5, mobile device 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com