Ammonium recovery and zero discharge technology and system of alumite-titanium wastewater

A zero-discharge, waste water technology, applied in ammonium chloride, ammonium halide, water/sewage treatment, etc., can solve problems such as inability to realize ammonia recycling, easy corrosion of equipment, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

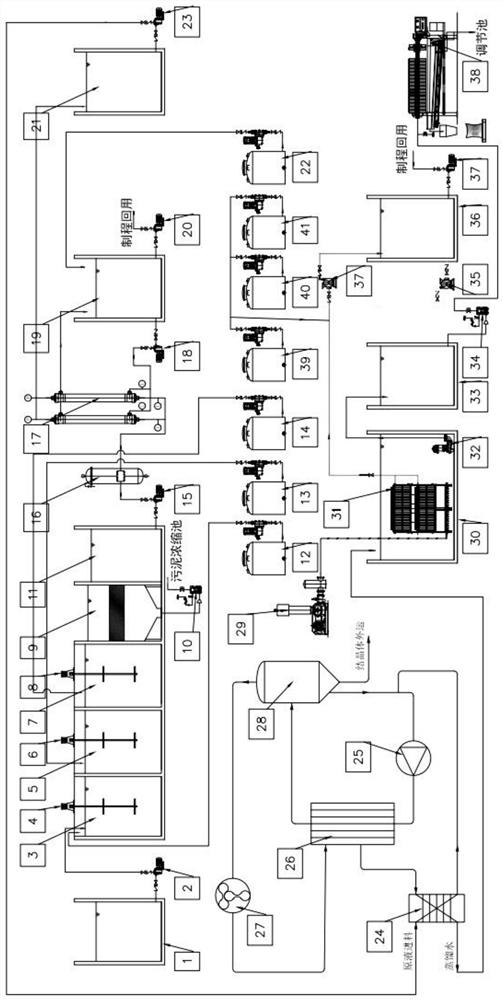

[0085] Such as figure 1 As shown, the present embodiment provides a system for ammonium recovery and zero discharge of alum-titanium wastewater, which uses AEM membrane method for deammonization and online recovery of ammonium chloride technology; the system uses evaporation desalination technology dominated by MVR mechanical vapor recompression ;The system adopts MBR membrane bioreactor to remove COD technology in wastewater. This system includes pH adjustment system, precipitation system, ammonia removal system, evaporation condensation system and COD removal system;

[0086] After the wastewater is pumped out of the regulating pond 1 through the regulating pond lifting pump 2, it flows through the pH regulating system, the sedimentation system, the ammonia removal system, the evaporative condensation system and the COD removal system in turn to realize reuse.

[0087] The pH adjustment system is used to adjust the pH of the wastewater to a specified pH value, and in this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com